DISCLAIMER: This topic is for discussing these types of breakers. The 10A "Instant trip" example pictured above might not be right for your application. Choosing the right Amperage rating and Time delay should be based on several factors and less than or equal to the nominal output rating of the transformer to which they are connected. If you think you may want to use a breaker of this style and you are unsure of the correct model, please ask for help here in the Electrical Forum in choosing the right one for your application.

Airpax Snapac Hydraulic-Magnetic Circuit Breaker Internal Mechanisms - Updated 12/4/2021

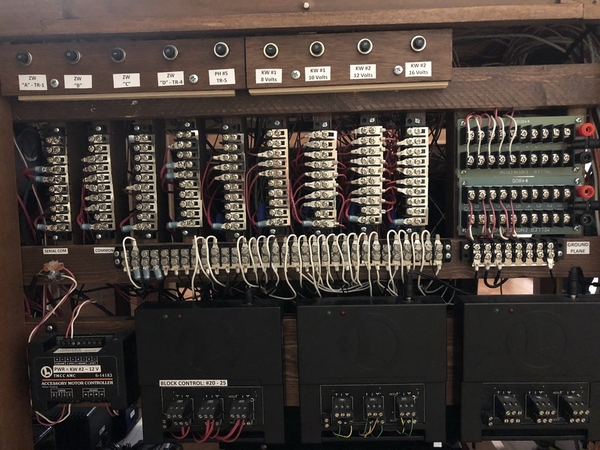

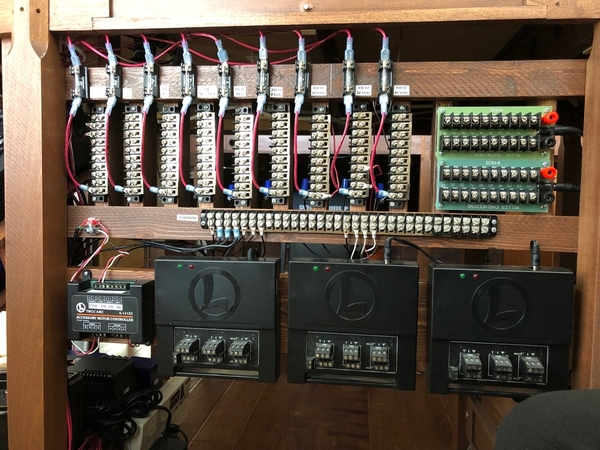

Introduction: These very fast acting circuit breakers are ideally suited for use in helping protect the sensitive electronics within modern Locomotives (TMCC/Legacy, Lion Chief (all versions), DCS, ERR and others especially when power is supplied from postwar transformers. These Airpax breakers are ideally suited to use on a layout when a mix of Command and Conventional Locomotives are run.

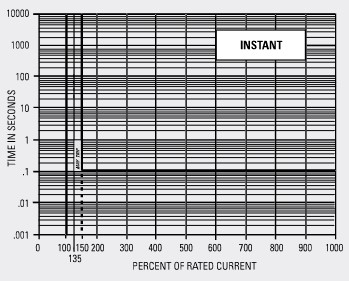

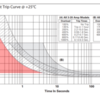

The Airpax "Instant" models presented here will trip in 1/10th of a second when their rated current (in Amps) is exceeded. They are faster than fast blow fuses and much faster than the original internal Thermal breakers that came stock inside postwar transformers.

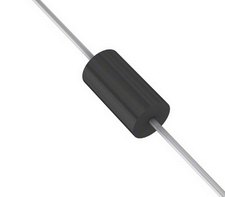

The other part of helping protect locomotives' electronics is combining fast acting breakers with TVS (Transient Voltage Suppression) diodes located strategically around the layout. Since there are numerous other references on this Forum, I will not go into detail about those here.

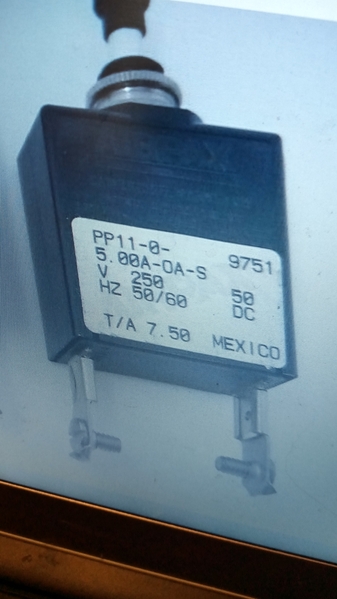

When I first read about these products here on OGR in early 2021, I decided to learn more about them. This series of hydraulic-magnetic breakers is called AirPax Snapac and is made by Sensata/Airpax.

Their data sheet is attached below.

There is more information on the web about their larger cousins (for example https://www.youtube.com/watch?v=sJU2pTdUyY0 ) used for higher voltage and amperage circuits, how they work and cut-away animations, but I was unable to find details on the inner workings of these smaller Airpax Snapac hydraulic-magnetic versions.

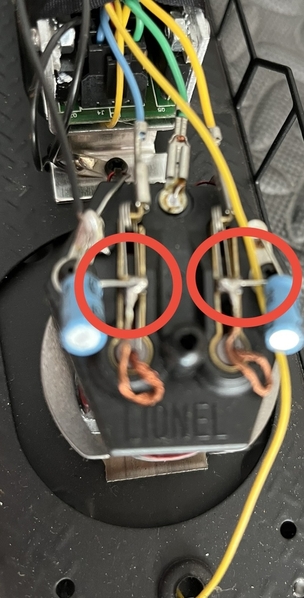

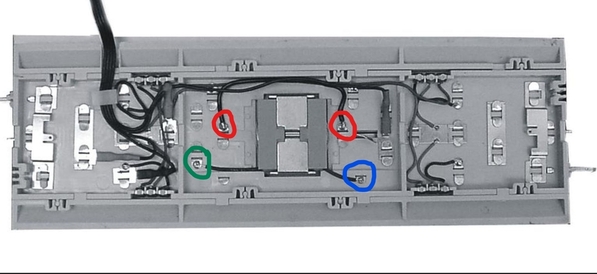

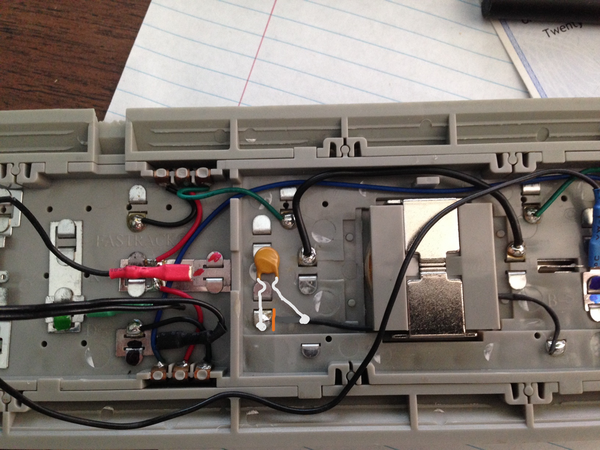

I decided to cut open one of the Airpax Snapac 10A “Instant” trip breakers. They are very similar, in that they have an Arc Chute (for dissipating the arc created by the opening contacts when they trip). They also have what appears to be a gas filled piston inside a coil, but there is one subtle difference in the way it activates the trip linkage. As the current in its stationary coil rises towards a set value, the resulting increase in the magnetic field overcomes the spring tension on the disconnect mechanism and pulls on a lever and disengages the contacts.

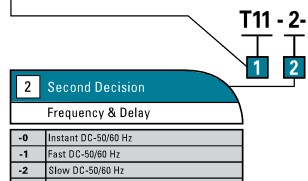

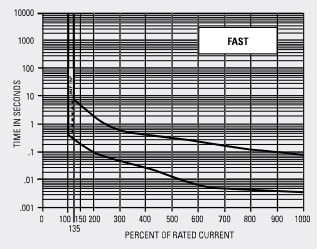

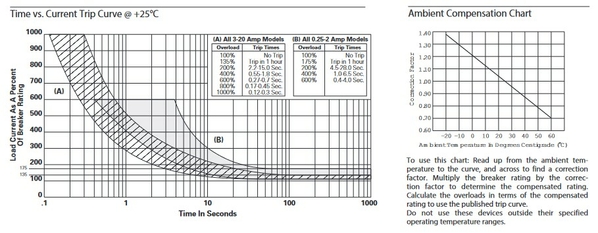

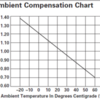

Airpax Snapac hydraulic-magnetic breakers are available with different time delays before tripping at the rated current (Amps). They come in Instant ( 100 millisecond delay), Fast (slower than the Instant and the delay time varies by how much above the rated current the actual current flow through them is for a variable period of time), and Slow (which has delay characteristics similar to a Slow Blow fuse).

Choosing the right type of breaker is dependent upon many factors and choosing correctly can mean the difference between experiencing nuisance tripping before the the optimal current flow is reached in the protected circuits, to just right protection, to being either to slow or overrated and not providing adequate protection to prevent damage to the transformer and what's connected to it.

Here are links to the Airpax Snapac "Instant" trip Series Breakers

5 Amp PP11-0-5.00A-OB-V https://www.onlinecomponents.c...00aobv-10090638.html or https://octopart.com/search?q=...ency=USD&specs=0

7.5 Amp PP11-0-7.50A-OC-V https://www.onlinecomponents.c...50aocv-10090644.html or Link to Alternative overseas Distributor or https://octopart.com/search?q=...ency=USD&specs=0

10 Amp PP11-0-10.0A-OB-V https://www.onlinecomponents.c...00aobv-10090622.html or https://octopart.com/search?q=...ency=USD&specs=0

12.5 Amp (no button markings) PR11-0-12.5A-XX https://www.onlinecomponents.c...125axx-43802931.html or https://octopart.com/search?q=...ency=USD&specs=0

Links to the Fast and Slow varieties are not included here, but can be found on the same website. Their part numbers differ by having a PP11 -1 - xxxx(Current rating) for Fast, and PP11 -2 - xxxxx(Current rating) for Slow.

Here is some basic information on choosing the correct Amperage rating for a breaker:

There are a few electrical fundamentals in addition to the trip delay time one should understand when choosing a breaker. The transformer Output ratings are a good place to start. Here's what they mean:

Volts - (electrical energy potential) in Conventional operation this sets the train speed.

Amps (current flow) - More Locos, cars and such (and shorts) pull more current through the circuit from the transformer. The transformer only delivers as much current as required by the load, up to a point. This point is it's Output rating.

AC Transformer Output ratings are usually given in either Watts or VoltAmps, both of which have essentially the same meaning when choosing breaker size.

Watts = Volts x Amps = VA

or

Watts/Volts = Amps

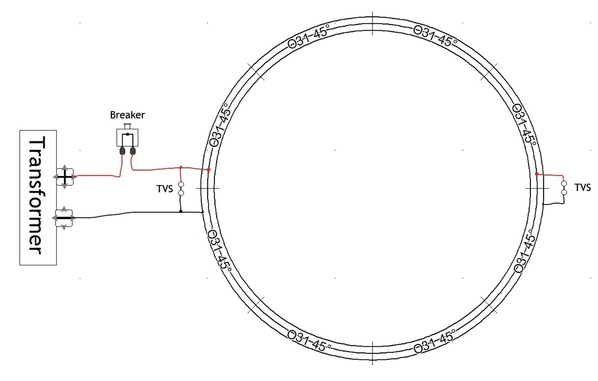

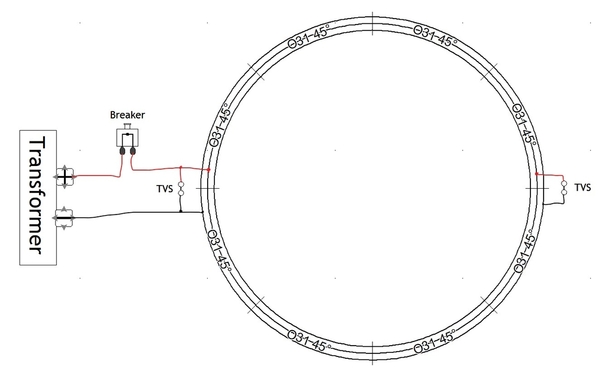

An often asked question is how to connect a Circuit Breaker and TVS Diodes. Here is a very basic example of a simple loop connected to one transformer:

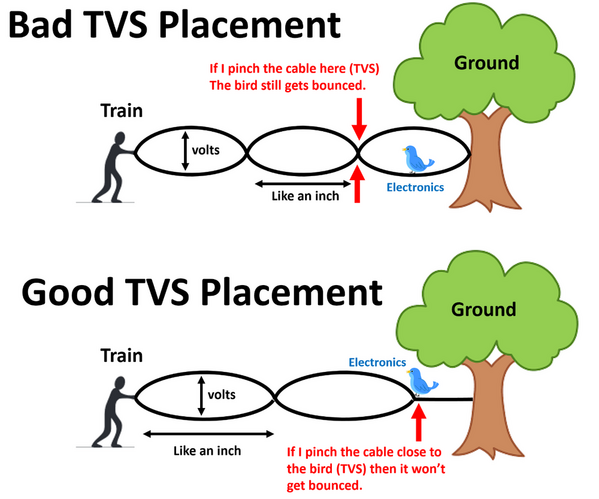

If you're looking for the ultimate in protection for your Legacy locomotive's electronics, installing TVS diodes inside the locomotives, on the PCB track power inputs is the best way to protect their sensitive electronics. TVS installed on the transformer outputs is a good step, but high frequency voltage spikes will travel past these.

Here's a link to the Topic started by Adrian! and his explanation of how this happens:

from that topic:

I hope this helps.