Okay guys

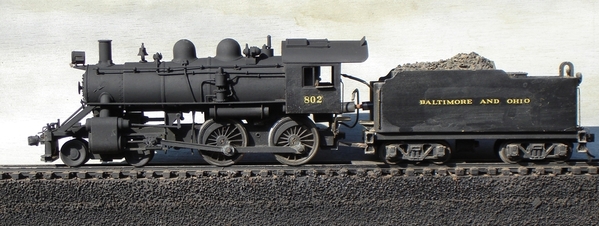

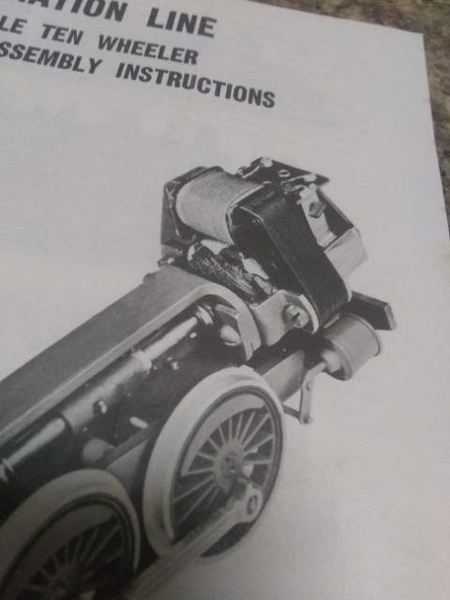

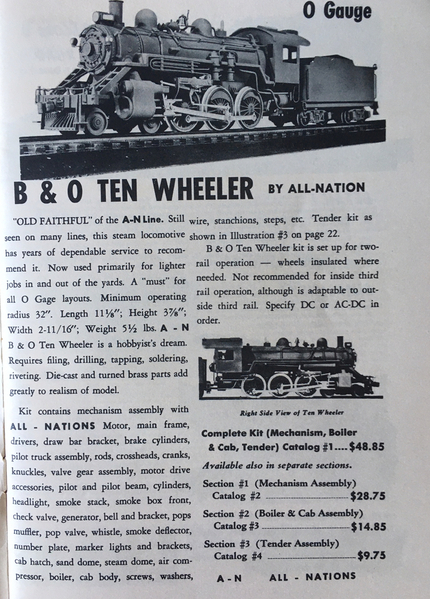

I imagine most of you who have been into this hobby for a while have had (or still have) this iconic model:

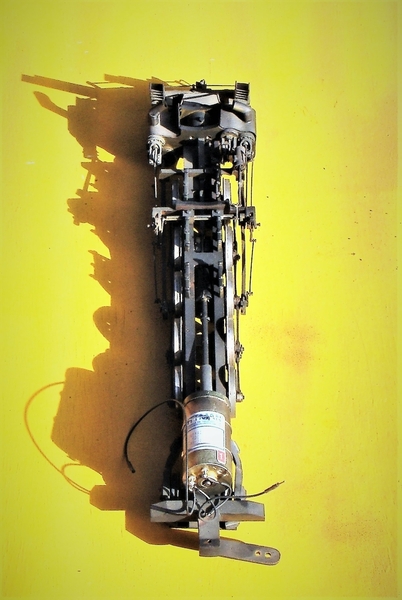

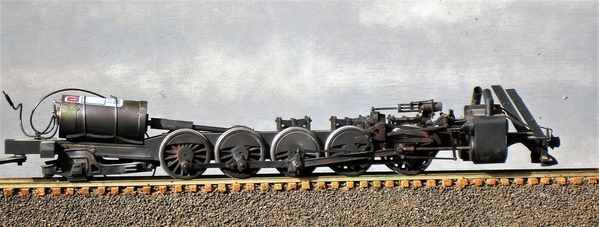

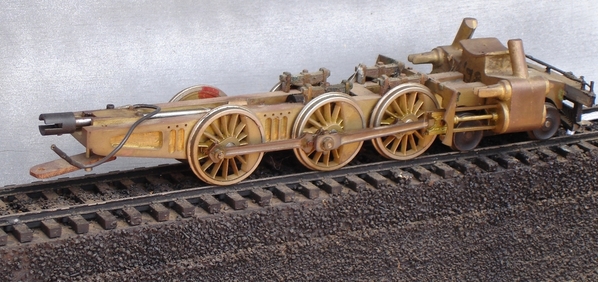

(eBay listing photo...)

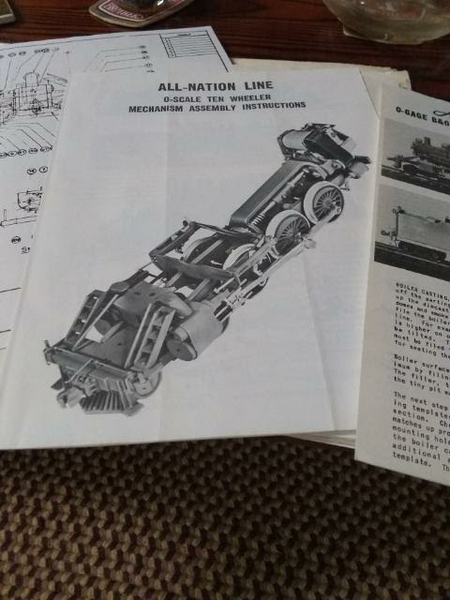

I picked up an example this past week, and it should be here sometime in the future; while I wait for it's arrival, I would like to learn something about its construction and perhaps pick up a few pointers on what to look for.

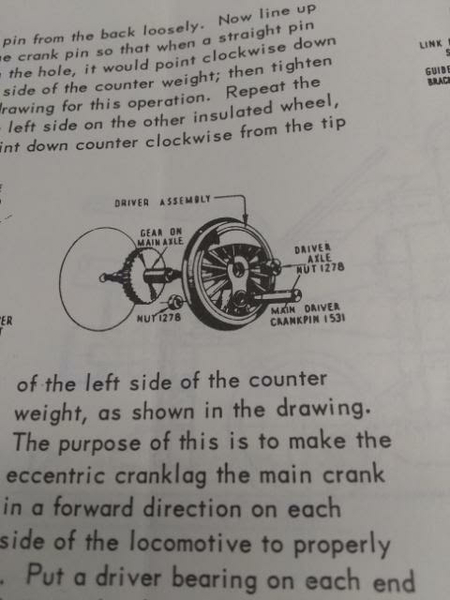

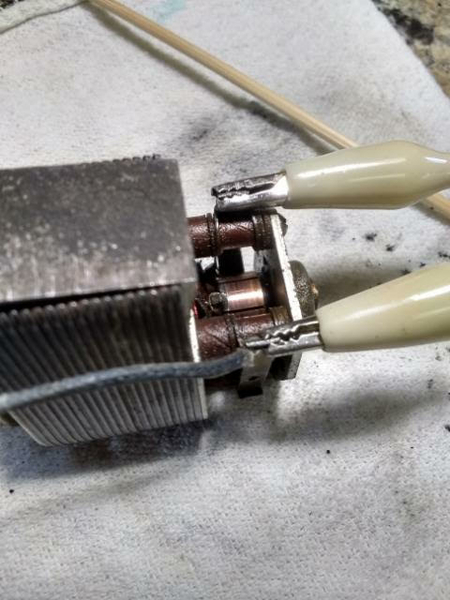

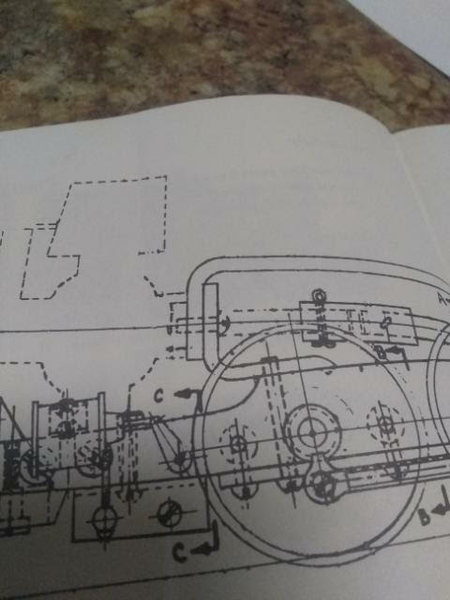

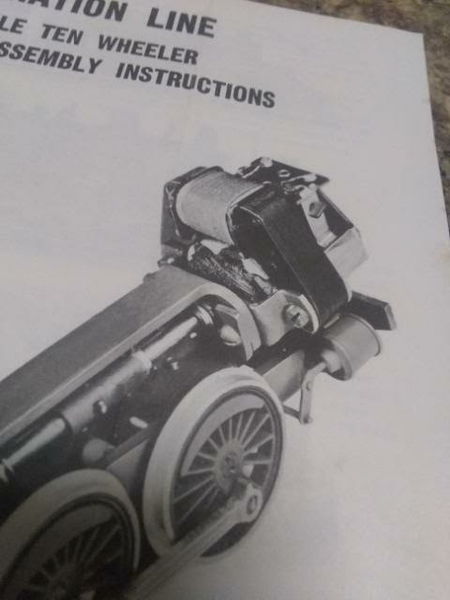

The main driver on the opposite side is out of quarter, and it looks like some of the valve gear will need to be replaced; as per usual, any eBay engine I get will need to be disassembled, cleaned, etc...which leads me to my main question: how is the boiler/cab attached to the frame? Is it like similar-vintage HO, with a screw up through the cylinder block and maybe a couple under the cab?

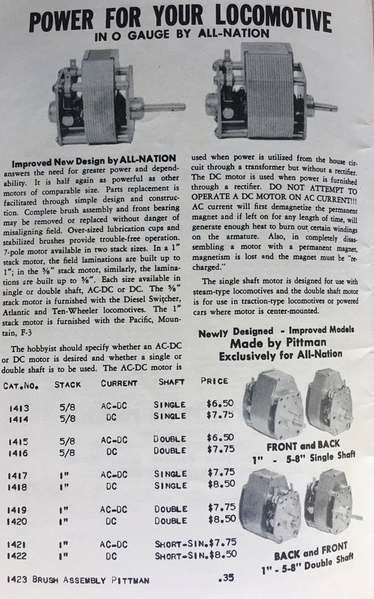

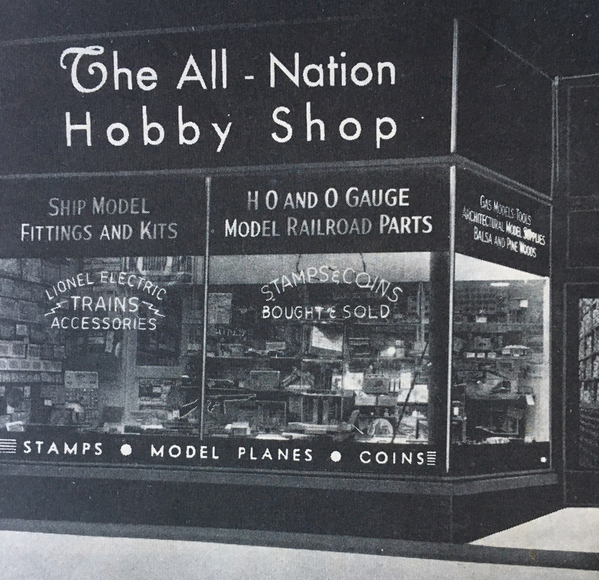

It's my understanding that this (and others) were owned by an outfit called "Babbitt": is that still a source? I'm not finding a whole lot of info on the 'web...

I appreciate in advance any and all comments and suggestions. ![]()

Mark in Oregon