quote:

Originally posted by Bob Delbridge:

All this brings up questions for me.

Most of these parts/kits were made at a time when the prototype was readily available/accessible. Someone could take photos, measurements, or even obtain the necessary drawings to produce a piece in o scale.

These days there's very few prototypical items that are accessible for someone to do the same thing. Most folks would have to travel long distances to take photos or measurements, and that's if the item is even available. I've got a topic going on a Seaboard Vanderbilt tender, how many of those are store around the country (I expect zero).

So how does someone go about getting the data to build a single piece, let alone a master so that multiple pieces can be made?

Do you copy someone's 50 year old work (that may or may not be accurate), do you go around begging for photos, drawings, etc (I hate to admit it but that's what I'm having to do with this Vandy tender), or is all of this lost for future projects?

As far as the Vanderbilt tender goes, I'm almost positive I'll have to fake the underframe, all photos I've seen so far only show the topside and outer surfaces.

Wouldn't be great if this kind of data was donated to the NMRA for future modelers?

Most of these parts/kits were made at a time when the prototype was readily available/accessible. Someone could take photos, measurements, or even obtain the necessary drawings to produce a piece in o scale.

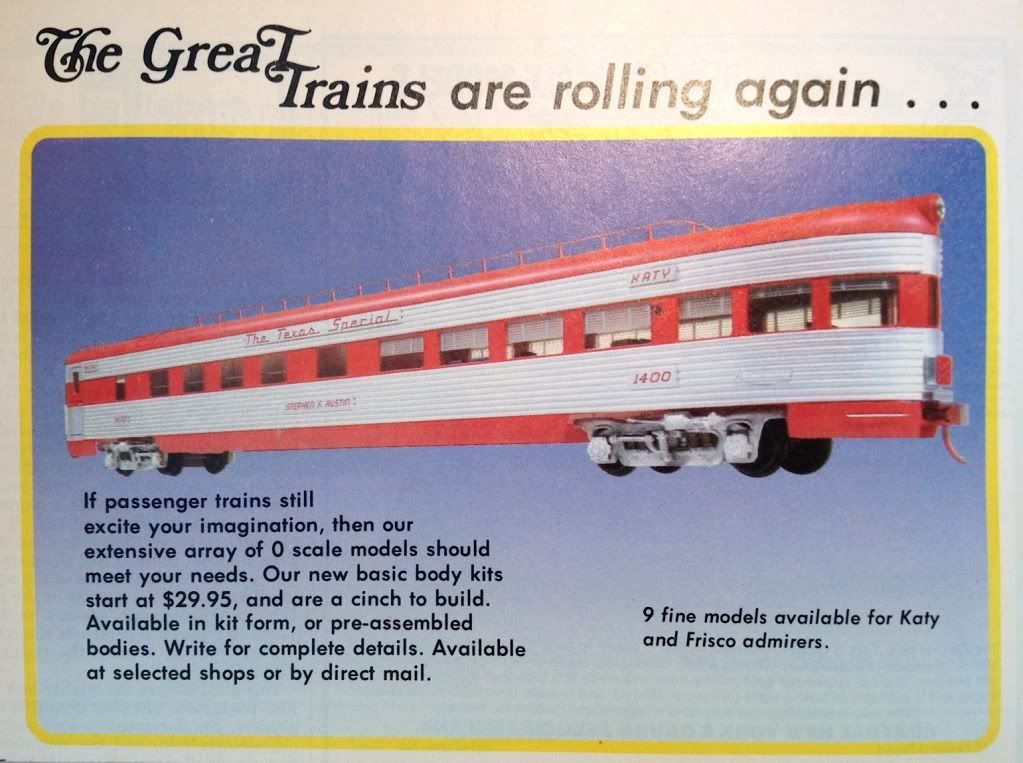

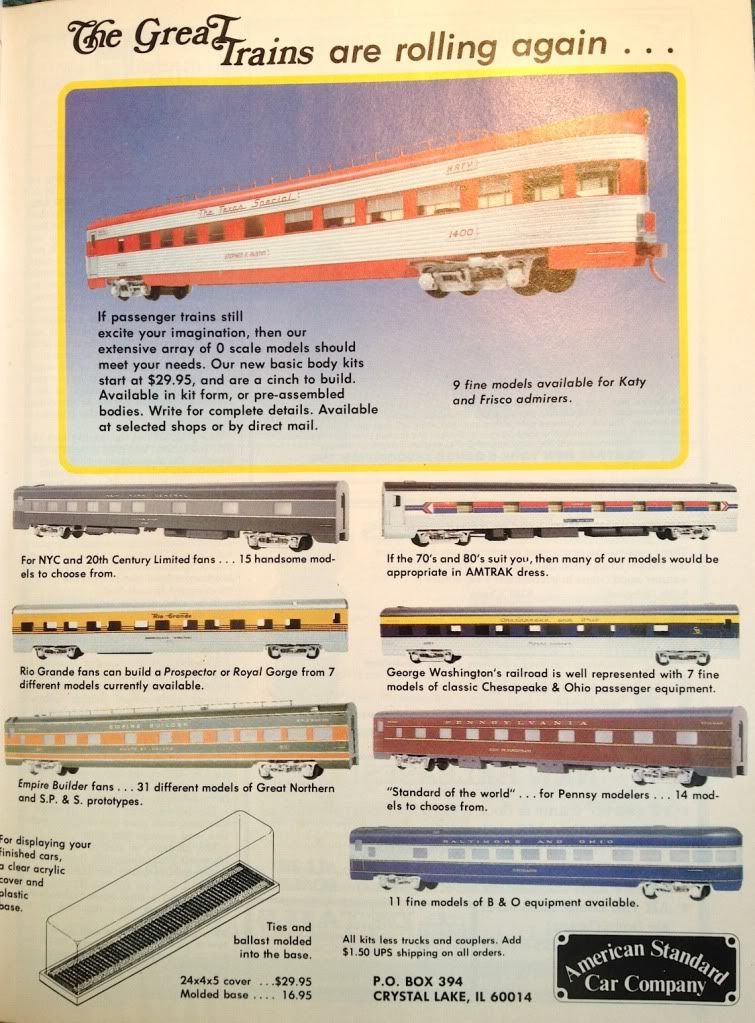

The kits we are blogging about in this thread came along in the late, late 1970's more like 1979 into the late 1990's long after these "Great Trains" were replaced by Amtrak Amfleet and Superliner gear. Unless a guy went to a museum or found some Heritage cars on the Amtrak's 1980's Broadway Limited technically that was into the 1990's your statement that a guy could run out and measure is incorrect just as the same today. These were post Golden Era kits bro... The AD states: "The Great Trains Are Rolling Again? review: Ad is from 1984, not 1954!

Do you copy someone's 50 year old work (that may or may not be accurate), do you go around begging for photos, drawings, etc (I hate to admit it but that's what I'm having to do with this Vandy tender), or is all of this lost for future projects?

Do you copy someone's 50 year old work (that may or may not be accurate), do you go around begging for photos, drawings, etc (I hate to admit it but that's what I'm having to do with this Vandy tender), or is all of this lost for future projects?Begging is a little bit of a long shot there..

I personally do a lot of research for brass importers of models dating back long before I was born into the 1940's. To date I have not begged anyone for material. Books, slides, eBay slides, historical societies, known experts, and so on are more than adequate for most research. Color samples are a challenge as we have discussed before in this blog; good drift cards and color chips are always a challenge especially with paint fade, color film dye changes and bleed. You might consider contacting the historical societies and or libraries for material on the Vandy Tender you are seeking. I doubt you need to beg some guy at a toy train show for his dads collection of contact prints. G.O.D.'s and erection drawings may be difficult to locate but these items are generally available to a modeler free of charge or at a photocopy fee from a historical society. Books also may have published your needed data; have you probed the books yet about the tenders? I am sure a score of good accurate books and or magazine articles have been published about your tender, a little research I am sure will turn up the needed information.

As far as the Vanderbilt tender goes, I'm almost positive I'll have to fake the underframe, all photos I've seen so far only show the topside and outer surfaces.Keep looking, try the state historical society where the prototype was built. Look into the Locomotive Builder Encyclopedias, contact the railroad historical society, ask for some names of known collectors of G.O.D. materials. I doubt there is not a record of this tenders frame. Look at brass imports, perhaps an importer like Overland or PFM already did the tender accurately based on found drawings.

I am off my soap box now too; your comments are a man frustrated but giving up is not an option. Be resourceful, pounding the pavement at gypsy train shows is a crap-shoot. Most of these guys don't know there way out of a paper bag anyway. Get in touch with the historical societies, museums like the Colorado Railroad Museum or Illinois State Railway Museum both of these organizations have excellent libraries, and look into the state historical societies for the manufacturer and see where that leads you. It is a maze but if its worth doing its worth doing right.