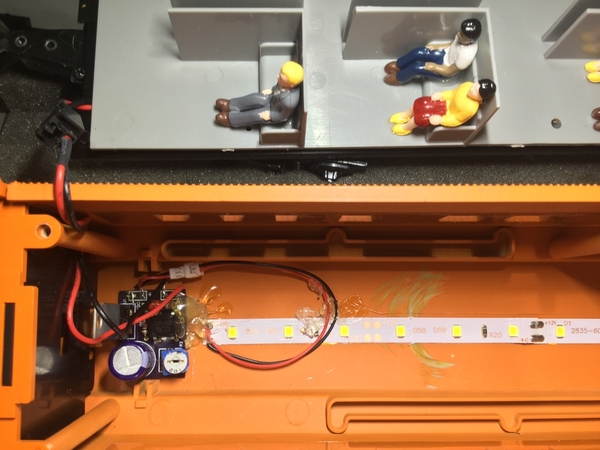

Here is a link to the board on OSH Park.

https://oshpark.com/shared_projects/Ah9bQ5RM

This is just a quick BOM.

This first section contains the actual parts I ordered from Digi-Key.

Digi-Key Part Number

Manufacturer Part Number

Manufacturer

Description

DF005M-ND

DF005M

ON Semiconductor

BRIDGE RECT 1PHASE 50V 1.5A 4DIP

LM317TGOS-ND

LM317TG

ON Semiconductor

IC REG LIN POS ADJ 1.5A TO220AB

P5168-ND

ECA-1VM471

Panasonic Electronic Components

CAP ALUM 470UF 20% 35V RADIAL

490-4808-1-ND

PTGL07BB220N0B52A0

Murata Electronics

PTC RESET FUSE 250V 130MA RADIAL

277-1722-ND

1984620

Phoenix Contact

TERM BLK 3POS SIDE ENT 3.5MM PCB

277-1721-ND

1984617

Phoenix Contact

TERM BLK 2POS SIDE ENT 3.5MM PCB

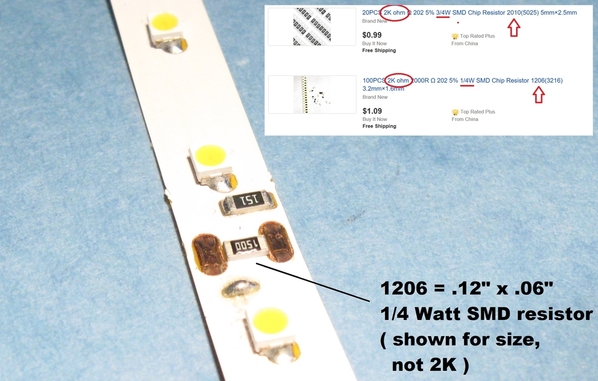

This section contains Digi-Key parts comparable to items I purchased from other sources, primarily Amazon.

Digi-Key Part Number

S27QCT-ND

Manufacturer

Stackpole Electronics Inc

Manufacturer Part Number

CFM14JT27R0

Description

RES 27 OHM 1/4W 5% CF MINI

Digi-Key Part Number

3296W-201LF-ND

Manufacturer

Bourns Inc.

Manufacturer Part Number

3296W-1-201LF

Description

TRIMMER 200 OHM 0.5W PC PIN TOP

Although there is a place for it on the PCB, I did not install the DCS choke (L1 on the PCB). I believe an appropriate part number is listed somewhere in this multipage thread.

***ETA*** If I researched this correctly, here is an appropriate part for the DCS choke.

Digi-Key Part Number

535-14428-1-ND

Manufacturer

Abracon LLC

Manufacturer Part Number

AICC-02-220K-T (5K/REEL)

Description

FIXED IND 22UH 285MA 1.35 OHM TH

Hope this helps.

![]()