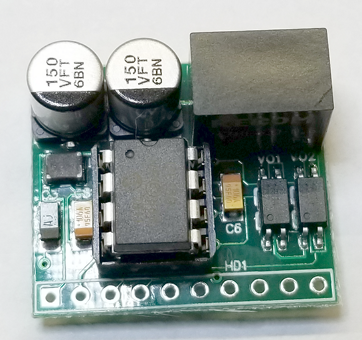

The reason for my option was as I stated, sometimes I need a common AC and DC ground. Other times, such as my passenger car lighting module, I don't have that requirement and I use a bridge rectifier.

The resistor is probably not going to do the trick. You can buy the proper 28V rated module for the same price on eBay, that's the way I'd go.

You could use some back to back 5V Zener diodes to drop the voltage a bit for each module. A kludge, but it works. You still need the other components, rectifier and capacitor, also the choke if you use DCS.

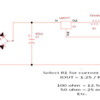

If you're going to get into soldering components together, you can probable roll your own easier than using the modules. For low currents for LED lighting, constant current is the way to go. You can tune the brightness by varying the resistor value. This is basically how my lighting modules work.