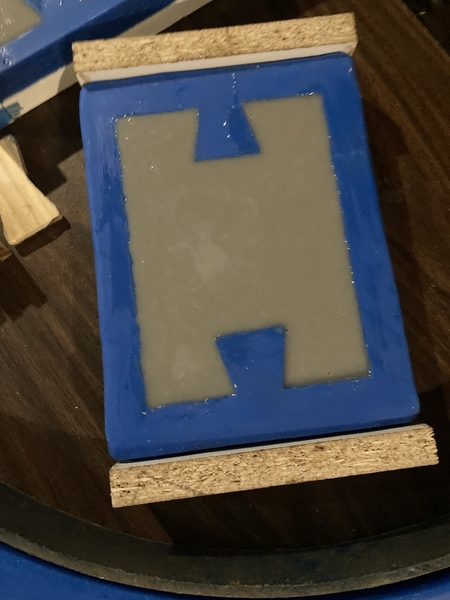

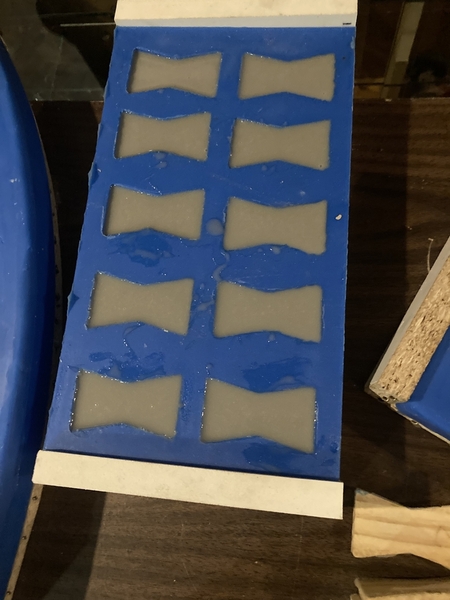

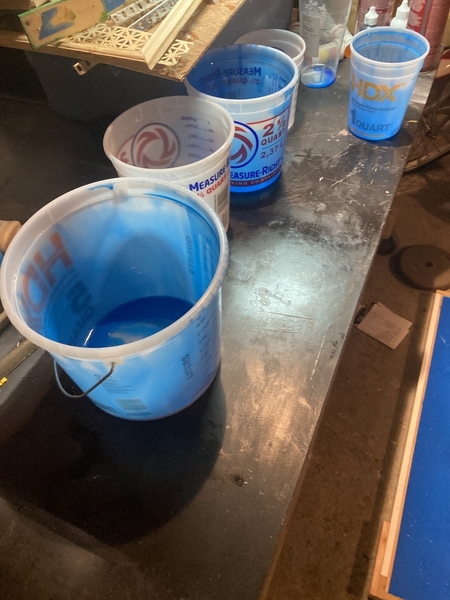

@Mallard4468 posted:I misunderstood your process - I thought that you were planning to make all of your pieces from wood, but now I understand that you are making molds. Since you are using solid wood (rather than plywood), the pieces will expand and contract across the grain with changes in humidity. They may also cup or warp if one side is left unpainted. However, if they are only being used to build molds, you might be done with them before wood movement is an issue.

Here's an article regarding considerations for wood movement: https://www.thisiscarpentry.co...ntent-wood-movement/

As a carpenter by trade I do know about what you were referring to . Still a good article to refresh the mind . As for the pieces of wood I’m using I’m not too worried about drastic swelling or twisting. Famous last words LOL. Thanks for your concern nonetheless. It’s nice to have someone looking after you making sure projects projects go smoothly.