As many times truck side frames are missimg off the old 1970s era Atlas F9s, does anyone know if the current Atlas 140952 side frame (if available) will work or have another suggestion?

Replies sorted oldest to newest

The "old" atlas o mechasnisms are totally different than the new ones and the truck mounting is totally different. The new side frames will not fit/work on the old trucks with out a lot of kitbashing and converting work.

That unit is unique It was built for a low price market and is totatlly different from typical trucks. The easiest way is buy an extra unit and use it for parts. That way you get extra geared axles, just in case" and gears, and sideframes. You could get one with a battered shell since you only want the mechanical parts.

This is along the same lines, Has any one rebuilt these trucks or the Rivarossi FM trucks?

You can use the P&D hobby shop drives made for these. Will give a robust drive system. The old drives will work for a while but gears eventually will split not worth the bother unless you can find some donor engines for parts . I normally gut the old Atlas and use at dummies and use something with power and a better drive to pull them.

Agree the Roco F9 drives have some good qualities but the awful truck design is terrible, tending to shed the truck side-frame like a crispy scab. The NWSL wheel/axle/gear replacements mitigate some of the drive issues but (opinion) ultimately still a dead end, though at least spawning a good after market business in drive replacements. I'm weighing the efficacy of the "John Armstrong" modification to the truck frame as I sit on huge junk inventory of these.

The Rivarossi drives on their FM CPA-4-1500 model is a completely different issue, basically a truck mounted version of their HO drives, awful for any real operation but not bad if you just want to run around in a circle with a light delrin trucked consist. I like them if for no other reason than they sound really cool.

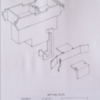

You could make a silicon mould ( which I have done but 5% bigger for brass casting ) and cast it in Urethane. The rest of the mechanism can be fixed and made more robust on a small budget. We have discussed this previously, and not so long ago, I think a search for Atlas ( Roco ) F9 should find it. The suggestion to buy a couple for spares is a good one. Above is how I mount the truck side frames, and new pickups, the angle piece is brass, but it could be aluminum or plastic. I use brass edging from the Till suppliers. cTr...( Choose the right )

You could make a silicon mould ( which I have done but 5% bigger for brass casting ) and cast it in Urethane. The rest of the mechanism can be fixed and made more robust on a small budget. We have discussed this previously, and not so long ago, I think a search for Atlas ( Roco ) F9 should find it. The suggestion to buy a couple for spares is a good one. Above is how I mount the truck side frames, and new pickups, the angle piece is brass, but it could be aluminum or plastic. I use brass edging from the Till suppliers. cTr...( Choose the right )

Attachments

I had 4 of the Atlas F9s. One was kitbashed into a B unit using a urethane shell I found at a show. They all ran 25-30 years on my layout with the original drives. I always ran them as pairs because they are light weight pullers. But with trucks that roll a pair was fine for 15 to 20 cars on my 1 1/2 percent grade. I shaved off the cast on grabs and put on wire ones, and move portholes to make F7s and I filled in the pilots.

I never had a failed gear or any other problem with them. The second pair was sometimes a little jerky due to gearlash I think when running light. I never had a sideframe fall off either. But the sideframes are a flimsy assembly I did break one while do maintenance.

I also had a pair of the original Intermountain GP9s which had a copy of the same drive. Those had a little more gear lash, but again no broken sprockets or gears or whatever.

I think for a home layout, they work out OK as a low priced power source.