Hi fellow O Scalers:

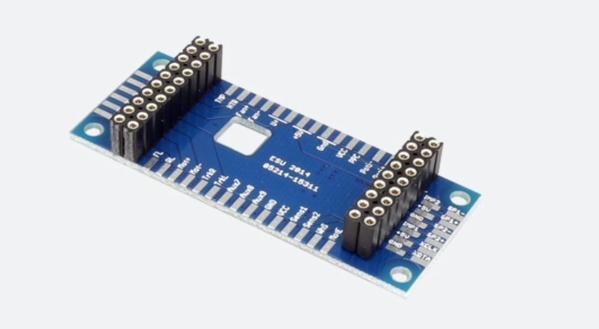

Here are some before and after still shots of my recent ESU Loksound Select L sound decoder installation in my CP Atlas O MP15DC. Our Austin O Scale group had a great little gathering over Austin Bill's wonderful 2-Rail O Scale layout last week, so I shot a little video of this loco in action (link at bottom) to go along with the still shots. This locomotive is an Atlas Gold Series model with a factory equipped QSI sound decoder and I wanted to upgrade to a more recent sound decoder to get a more realistic sound for this prime mover along with adding an ESU Power Pack (ESU's version of a Keep Alive). I used a thick piece of brass sheet as a base to mount the new decoder and the ancillary components; consisting of a home-brew resistor board for LED headlights, and keep alive circuits. I used my Sherline table top mill to machine some wire restraints and drill holes for the 2 mm screws I used to secure each of the components. I kept the OEM speaker in the fuel tank as it seemed to do okay. I may upgrade this at some point to see if it will make much of differnce. Since the Loksound Select sound decoders come without sound files installed in them (Loksound does this to keep decoder costs down on the Select line of decoders), I had to purchase the Loksound programmer to upload the EMD 645 12 cyl Non-turbo sound file to the decoder. Most Loksound prime movers have three separate sound files, L (Large Scale), HO, and micro (for N scale decoders). I don't know what exactly makes each sound files different and can only guess that the larger scale decoders must have larger memory capacity to store larger sound files. I would presume that the larger sound files have a higher sample rate and would yield better quality sound. However, on this installation I ended up going with the HO Scale scale sound file for two reasons: First, I started with the L version (large scale sound file) but was not at all happy with the sound quality, it was very bland and sounded like the recoding was taken from inside the cab of the locomotive instead of outside. The second, and more important reason, is that the HO version had an alternate "proto sound" file that can be enabled by setting one of the bits in a CV register. Setting this bit provides a feature that is akin to the TCS WOW sound "Auto Notching" feature where the sound "notch" is actually using the motor's BEMF value to adjust the sound loop and not necessarily the DCC throttle setting. Not all ESU Loksound files have this feature but I sure hope they continue to add it to their future sound file releases since they really do add a more prototypical sound. This little engine is now a blast to switch with as a result of this new sound decoder upgrade.

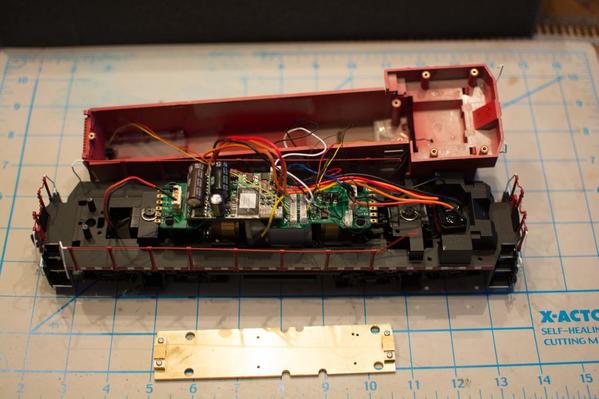

Before photo:

After photo:

Action video:

Scott Kay

Austin, TX