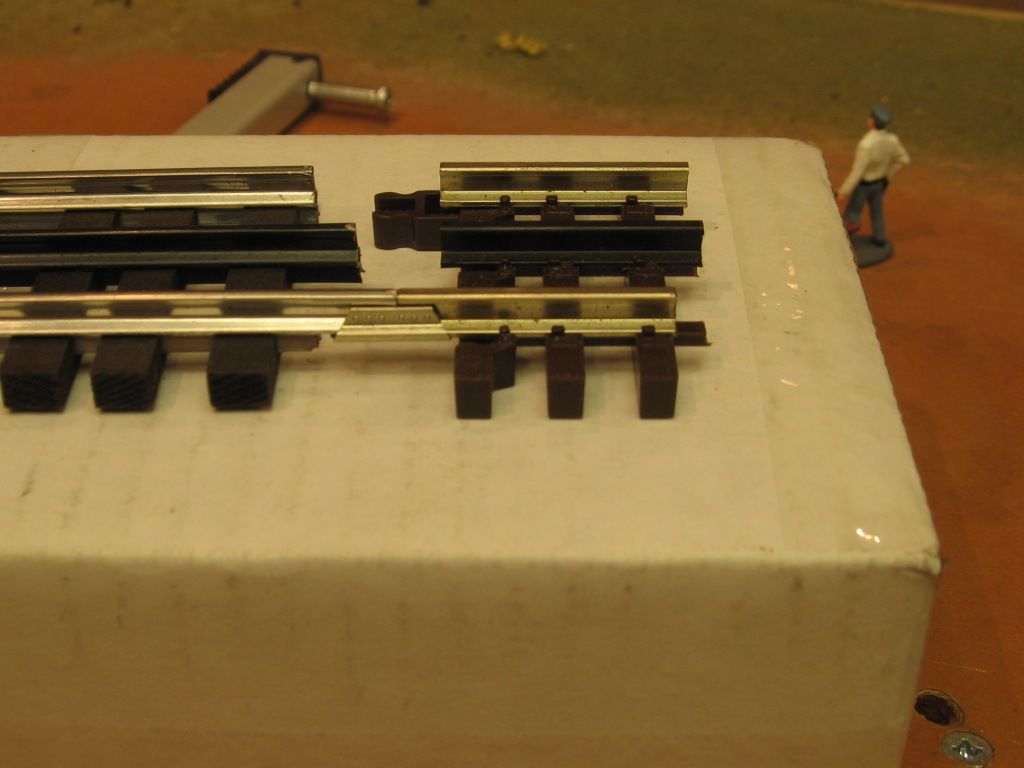

It seems that, when coupling Atlas track to Ross switches, or when adding Atlas uncouplers to Ross track, that the Atlas, flange mount, track joiners are a perfect fit.

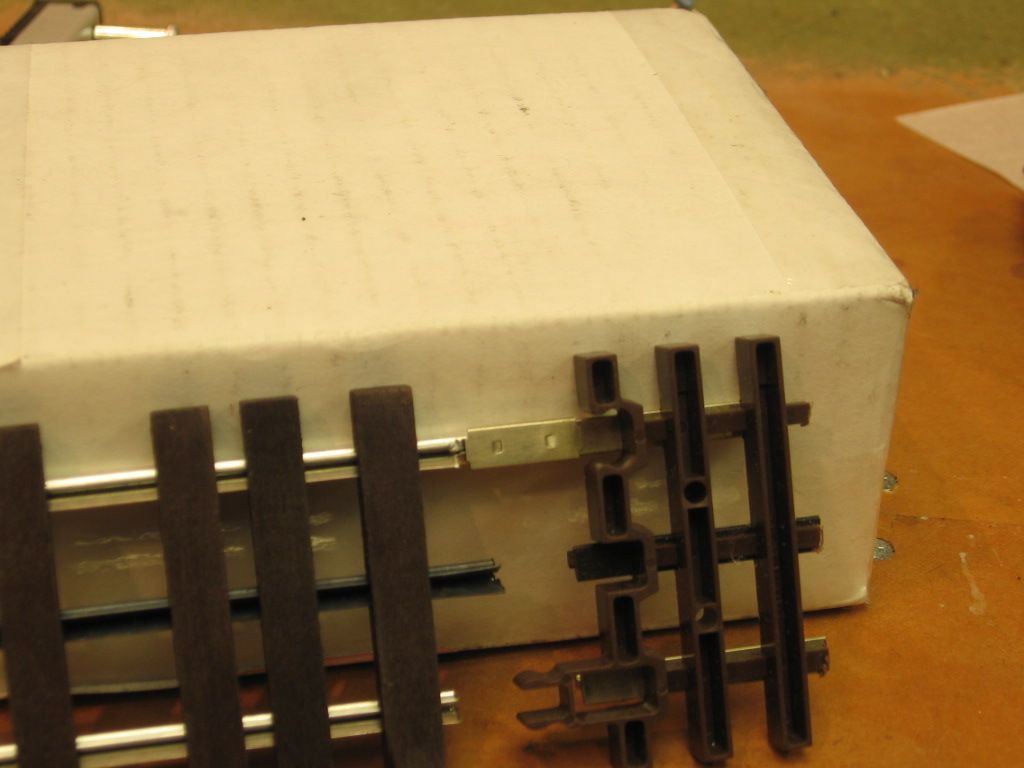

So then, since it seems to be difficult to get Ross track tight together with the pins that have the small ridge in the center, why couldn't all of the ross track be joined with the Atlas flange joiners? Yes, I realize that the joiners would need to be shortened a bit to fit between the Ross ties, especially when using the Rossbed style roadbed, preventing adjustment of the ties.

I was thinking that, then, I could also use the atlas power drops in lieu of soldering wires to track at all of those locations. I could probably make my own Atlas style power drops a lot less inexpensively as well, and easier than soldering to the track. I realize that some areas would still need to be soldered, like non-derailing connections, etc., but it would cut down on track soldering by a large amount.

Am I missing something, or could this work?

Another option might be to still use the pins, but eith the addition of the Atlas style power drops.

Good idea, or not?