Hey guys,

I mentioned a project I am tinkering with in another post and I thought I would start a thread just for the build.

The project is to build a fully operational switcher type loco that is battery powered and WiFi operated with digital sound and PWM controllable LED lighting.

The parts and pieces:

K-Line front powered DC drive truck from some random diesel loco.

Battery (for testing) 1300mAh LiPo 11.1V 3S1P.

(2) Microcontroller + WiFi Adafruit ESP8266 HUZZAH breakout boards. One for the layout and one for the loco.

Motor Driver Adafruit Stepper Breakout.

and a bunch of plastic, wood, glue and wires lol.

Lets clear up a misconception about WiFi - NO YOU DO NOT NEED THE INTERNET TO HAVE WIFI!

Sure, in some cases where you want to use an scripted website to control a WiFi device you do need an internet connection. In cases where you are using just the WiFi to run a device based program NO YOU DO NOT NEED THE INTERNET. All WiFi devices have the necessary protocol and hardware to talk to each other. Whew... I will be using a self scripted Android app to control this loco and layout with my handy dandy tablet and phone.

I have already had several friends pipe up and say "you can't use a stepper motor controller to control a DC motor..." Sheesh. Yes, you most certainly can. A DC motor controller is an H Bridge style controller and a DC Stepper motor controller is based on 4 half bridges where each half bridge controls one of the multiple winding's blah blah blah. For my test, I use two of the half bridges to create an H bridge for motor control. This leave two half bridges to control LED's and maybe a coupler, we will see.

If you are a total electronics noob, don't be intimidated by this little project. Here is a secret "an H bridge is just some switches...". Very oversimplified but true, four transistors make the main part of an H bridge driver. Transistors are a switch.

Microcontrollers are a piece of cake. In this case the ESP8266 HUZZAH can be programmed with the simple Arduino IDE.

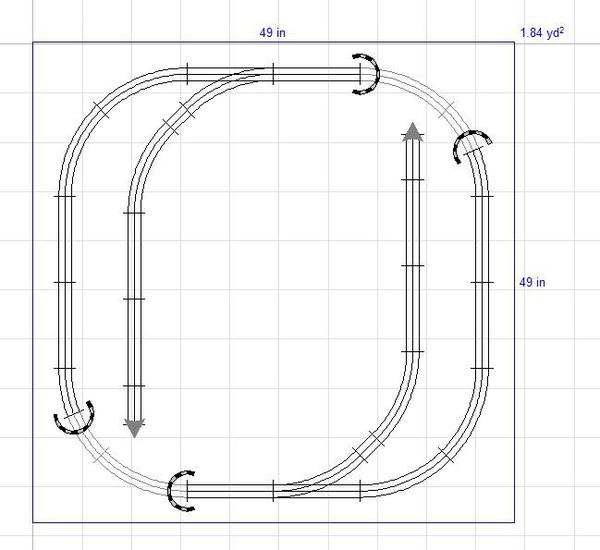

My plan - Control a train on dead O-27 track and control the lights and two switches on the little test layout. All of the O-27 track is slowly being crafted into two rail, wood tie O-27 (I know that will hurt a few minds) as are the two switches. I will show pics as I go.

The train parts

The mini 4X4 O-27 Layout

I hope you follow along and if you have questions or comments, please post them.