i agree with everyone that the benchwork looks fantastic. i plan on using the Mainne benchwork for a layout that will be built in a family room/basement and was wondering what type of wood was used for the insert to the open benchwork? thanks

ADIRONDACK RR: If you are asking about the sections where shelves are installed: I used 1/4" plywood, attached to 1X2" strips, attached to the rear of the Mianne benchwork legs, that served to provide the needed depth for the shelves. The shelving is from Glenn Snyder.

Attachments

This looks fantastic I have one question What the heck is a Great Room I only have Not so Great Rooms

Thanks. That’s exactly the information I need. I also checked Glen Synders website. He will even cut the shelving to fit.

Construction progress 5/19/19:

Electrical infrastructure now in place and it will soon be time to start laying track!

Circuit breakers, quick blow fuses and TVSs on all transformer posts:

I built this cool two story parking garage for my Legacy controllers:

Overkill on power for three loops, lights and accessories, but I'd rather have too much available than too little and I can have many variable voltage choices for accessories using the 2 KWs:

Attachments

STANGTRAIN, very nice looking Control Center, very neat job of wiring, nice use of SC2’s, great woodwork.....Thank You for the update....I envy your neatness, so, I will begin, in a few days straightening up my wiring and finish connecting the already dropped wires to streetlights, Atlas O uncouplers, buildings, etc. You have started my thinking processes with your electrical work. Happy Railroading.

Progress 6/10/19:

Two track mainline tracks installed and wired with cork roadbed (painted grey) installed. As I did in prior layouts, I plan to remove all tracks, glue ballast to the painted roadbed and re-install the tracks. Today I wired the "whisker" tracks at my turntable and the turntable is now operational once again! I had one "oops" when I was testing one of the tracks and had a dead short when the engine entered. I had wired the track in reverse. The powermaster quickly shut down power. Had it not, the powerhouse circuit breaker would have tripped and if it didn't, the quick blow fuse would have saved the day. Of course the TVS was on duty just in case as well.

It's so nice to get some trains moving again!

Next, I will continue with my plan to have an upper level track. I have the track cut and ready to install. My plan is to take the track to my garage, trace the track plan onto flattened boxes and then transfer the plan to 1/2" plywood for cutting. I'm still considering using 3/4" plywood but I think it would be overkill and harder to work with. I engineered this support that I plan to use for the upper level track:

Lightweight and strong with readily available 3/4"dowel and 3/4" square moulding held together with screws. Making about 16-20 of these may be a chore! The real fun will come when I build the supports for the section that attaches to the liftgate! Cutting the curved track to line up on the liftgate is the challenge. Since I already made the cuts here, I think I should be OK:

Attachments

Very inspirational and motivating- I loved the hierarchy discussion on your short circuit!

Progress 6/22/19:

Started ballasting and added extra ties to the "whisker" tracks at the turntable:

Added two analog voltmeters: 1 to display voltage at power master set to TR #5 that supplies power the turntable tracks. The second voltmeter (on the left) is attached to a rotary switch to show actual settings from my four variable voltage posts on my 2 KWs used for accessory power. This gives me the opportunity to display "fine tuned" power when needed:

Getting ready to start cutting plywood for the upper level track.....

Attachments

Progress 7/15/19:

Now that tracks have been installed, wired and ballasted on the double main line and turntable "whisker" tracks, I started to build the "modules" for the upper level track. Building the modules in the workshop is working out quite well so far. I am recycling girder panels, attached with liquid nails, from a previous layout - actually two layouts ago in PA. I added metal foil tape on the underside of the module that will be connected to my earth ground terminal strip in order to minimize TMCC signal interference. I also pre installed wires for track power as well as the earth ground connection, routed through a conduit:

Attachments

Amazingly neat wiring and I love the layout and your attitude about making work what you have![]() . Question for you, are you using one powermaster per handle on the ZW? From the picture,that is what it looks like. I plan on using powermasters if I get back to working on a layout (household renovation taking precedence along with yard work!), and I hadn't even thought about doing that, was going to use on A/B powermasters in each block.

. Question for you, are you using one powermaster per handle on the ZW? From the picture,that is what it looks like. I plan on using powermasters if I get back to working on a layout (household renovation taking precedence along with yard work!), and I hadn't even thought about doing that, was going to use on A/B powermasters in each block.

You said that you are pre-ballasting the roadbed and then installing track. What are you using for ballast? I assume something fine grained. Also, are you leaving the area under the ties without ballast or setting the track on the ballast? Can you tell us more about the procedure?

Thanks Bill

Looking great!

BIGKID: I use the following for track power: 1- PWC ZW with 4 - 135 watt powerhouses connected. The PWC ZW has 4 powermasters built in. I am using the two outer channels, AU & DU for track power and BU & CU for accessories. I am also using another 135 watt powerhouse connected to a legacy powermaster for the third track loop.

OGAUGENUT: I use the following method for ballasting which I am now using on the fourth layout: Using tubular Lionel track, I first put together and wire all trackwork and mark the center line with a pencil. Next, I remove the track and unplug wiring (using Molex solderless quick disconnect male connectors from Mouser, #538-19022-0004). Using the center line, I install cork roadbed which I first painted a mid to dark grey color. Next, I glue ballast onto the roadbed using white glue. Quite a few years ago, at a York train meet, I found a rubber ballast made by "Ballast King", 2721 Trinity Ct., Avon, OH 44011-1972, 440-937-6771 - need to call to see if still in business - no website then or now. I use a blend of a few of his products to get the right look that I prefer. Finally, I re-install track and wiring, then add extra ties and that is it. This method makes removing track / switches easy when the time comes to change the track plan or just service the switch tracks or for whatever. The beauty of the rubber ballast is that, since my layout is in my living space on a hardwood floor, the rubber ballast that inevitably falls is non abrasive and scratches are therefore avoided.

You have performed and accomplished some very technical and beautiful , impressive work. I can't wait to see the completed project'.. Congratulations on such a fine job'...![]()

Progress 8/5/19:

I constructed and installed all of the upper level "modules". The liftgate section was the toughest as it took some fine tuning but I got the tracks to line up well and the liftgate moves up and down freely:

Now that all tracks are installed and wired, it was time to bring out more trains for a trial run:

Even though they are simply going around in a circle (loop) it is pretty cool to see three trains moving at once!

Next step is to position buildings, etc. where I want them, build a road and install signals, crossing gates, etc. I am not in any rush now that I have trains running again!

Attachments

Looks to me like an 85" TV would fit.

Very cool indeed'.. I really like your shelfs'... Three running at once id fun'.

Enjoy all your hard work'...![]()

![]()

![]()

I've been making good steady progress on this smaller railroad that I hope will never be completely finished:

Now my progress has taken a few steps backward - A couple of days ago I heard an unusual noise when raising the liftgate. Upon examination, I found that the liftgate cable showed some signs of wear - actually fraying in two spots. Tim at Mianne told me the cable needed to be replaced. Unfortunately, in order to get to the pully on the motor that contains the cable, I needed to remove the plywood on the 2' X 2' section where the motor resides. I needed to remove one of the bolts holding the motor in order to get to the part which required removing track, scenery and accessories mounted thereon:

The pulley with cable attached is already on it's way to Mianne in Massachusetts via 2 day priority mail. Tim said he would replace the cable and ship back to me quickly.

Putting the pieces back together again will not be that hard. With the stuff off, I did get some ideas for changes, such as adding Miller signs here and there etc.

My recommendation to all using the liftgate is to try to minimize what you attach to that 2' X 2' area just in case something like this happens to you!

Attachments

What is that thing with it's head against the wall?

Eddie G: Glad you asked! It's "Little Stevie" - a stuffed and dressed doll representing that kid who touches or breaks something on the layout. In this case, the name came from my Son-in-law's father, Steve who once was visiting and adjusted (when I wasn't looking) my Lionel "Indian Princess" accessory causing the princess to get run over when the next train came by! She survived and actually Lionel packed two princesses with the accessory just in case this happens. "Little Stevie" has been part of my various train layouts for over 20 years now.

Attachments

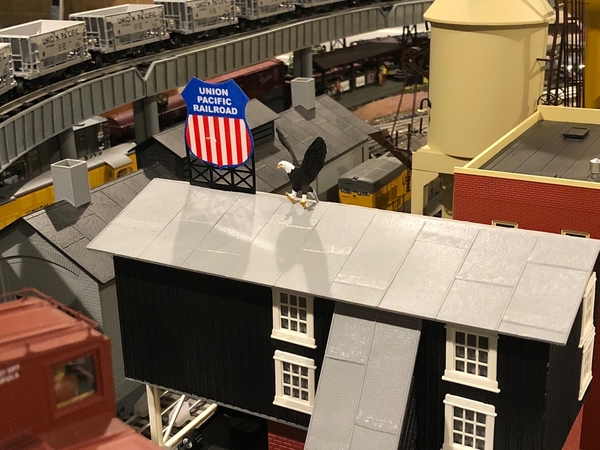

Continuing to make steady progress on the newer smaller layout. Today, I managed to install the last of my many Miller Engineering (OGR Forum Sponsor) signs:

Attachments

Very nice layout. Thanks for sharing.

bluelinec4 posted:This looks fantastic I have one question What the heck is a Great Room I only have Not so Great Rooms

Any room that you are still able to be in at most of our ages is definitely the great room

Stangtrain;

Wow - you have packed a lot of action into a relatively small space. I love the Mianne Benchwork, but to date, I haven’t done any downsizing... only added to my original layout.

I’d like to ask a question on your Miller signs. I have a few which I haven’t installed yet - one of which is the PRR sign you show:

Could you tell me how you installed it on the peak of the roof??? Mine has a rather chunky black connector which attaches just below the lowest black horizontal bar, so I was thinking I would have to cut a hole in my roof.

Thanks.

Attachments

Paul:

I cut a slit in the roof and needed to enlarge it a bit to have the sign sit properly - be careful not to flex the sign as I did and needed to order a replacement, LOL!

I hope this helps.

Stan

Attachments

stangtrain posted:

Thanks, Stan. My roof is thin and I thought that the additional space would screw up the connection to the sign. And I’ll make a point not to flex the sign!!!