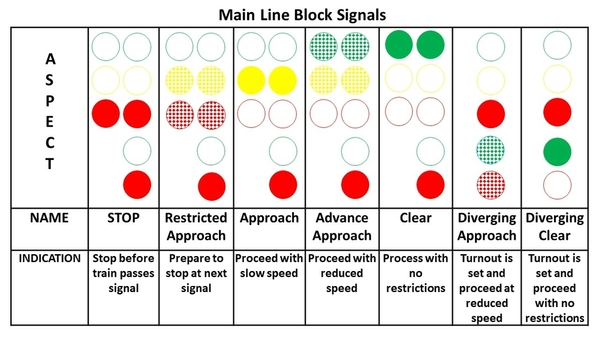

The layout I am planning will have over 200 signals and I would like to have them operate with a rule set. Layout Command, LCC, will be used to detect train locations and do the logic for the block and dwarf signal. I will break each track block into 1-3 sections with for occupancy detection. My LCC track occupancy detector cost less than $1 plus my labor. The signal aspect control and logic will be done by a RR-CirKits (company) Signal Tower (product name). It will cost $4 for each signal LED. To reduce the signal costs the Yellow aspect will be controlled by a 2-NOR of the Red and Green signals. The chart shows my current thinking on the signal rules. I am open suggested changes in the rules. The checkered aspects are blinking.

Replies sorted oldest to newest

CLICK HERE for a basic primer on NORAC signals. Click on the aspect you want to see at the bottom of the screen.

From a prototypical point of view, some your signal rules don’t match the prototype. For example, an Approach aspect always means “Approach the next signal prepared to stop.”

Advance Approach means “Approach the second signal prepared to stop.”

I have never seen a “Restricted Approach” signal. “Restricting” yes. Restricted Approach “ no.

SEE http://www.customsignals.com/track-config-library.php

AND http://www.customsignals.com/system-design.php

Terry Cs Custom Signals ultimate guide

I don't want to rain on the parade, but may I suggest that you give this plan some very serious study before starting? As one who has a functional block signal system on my modest sized layout, with 32 signals, I can tell you that there are two components:

- the signal system, and

- the rest of the layout and all the trains.

This is just my opinion, but you appear to have chosen a "lite" version of speed signaling. Speed signaling is somewhat more complicated than route signaling.

Prototype speed signaling is designed to require a train to reduce to a safe speed for whatever is coming next -- stop at next signal, proceed through a turnout that is designed for a specific maximum speed, proceed at Restricted Speed, etc. Model trains don't need all these aspects because, for one reason, you almost certainly will not have the full array of different length turnouts, and model trains are not as speed sensitive as to derailing, as are prototype trains.

Route signaling, on the other hand, indicates action to be taken in the block and at the next signal -- proceed, proceed on diverging route, approach, stop-and-proceed, stop. It requires a reduction in speed for some indications, but is normally only either maximum authorized speed, 30 MPH, or Restricted Speed.

Model trains don't need all the aspects of speed signaling, and a route signaling system can avoid the use of 3-unit signals with their more complicated aspects. Route signaling aspects are logical and understandable.

Who is going to run the trains in compliance with signal aspects? You seem interested, but will others have any idea what to do if their train encounters a red-over-flashing green-over flashing red aspect?

The relays will be somewhat more complicated with speed signaling. I see by your profile that you are an Engineer. Hopefully, that would enable you to understand how to install a signal system. The equipment you have chosen appears to be able to control the signals if you have the skill and patience to properly wire and program it.

You could easily spend several thousand dollars on the signal system you describe, with such a large number of signals.

It's your layout and your money, but I would strongly suggest that you talk with others who have installed prototypically operating signals on their layouts, before you make a commitment. Trainworx recently built a layout for a fellow who wanted the full array of CSX aspects. They could help you get in touch with him if you desire to find out what he uses, how well he likes it, how well it works, and how much of his retirement money went into the signal system.

This is the relay board for only one sixth of the number of signals you are wanting to use. There's a cable from the circuit board out to every signal, and additional cables daisy gaining the signals together. There must be an track circuit for each block, with two insulated joints per block. A signal system (as differentiated from "some signals") is impressive, but it's not a bed of roses. Good luck.

Attachments

Hi Number 90,

Thanks for the feedback. I took your advise and made the signal rules simpler.

I spent about a year designing a layout while on business trips on my laptop. Then I started to design the electronics to go with it and quickly found out that the electronics design is hard and taking more time than the layout design. I have been working on the electronics design for more than a year. After several emails with Dave Hikel I decided to use Layout Command Control, LCC. I will also use a combination of "Train Controller Gold" and JMRI. The LCC network will do the track occupancy detection and control the signals, turnouts, lighting and accessories. Train Controller Gold will have access to the LCC network for occupancy information and to control turnouts and accessories. Computer operation of the layout by Train Controller requires the occupancy information and control of the turnouts. I bought the LCC starter set and several Signal LCC nodes from RR-CirKits. I designed LCC nodes for occupancy detection and turnout and accessory control. The base software came from the OpenLCB group. I decided to use the RR-CirKits Signal LCC node to control the block signals because the software is more complex. The Signal LCC nodes needed for 200 3-Aspect Block signals is shown in the following picture. The nodes will be distributed around the layout and connected with CAT-5 ether net cable and not place on one board as shown in the picture. The Signal LCC cost for a block signal is ~$8.

The DIY occupancy detection LCC nodes for 216 track sections is shown in the following picture. It cost less than $1 for a track occupancy detector.

I have extensively bench tested the DIY LCC occupancy nodes with the Signal LCC nodes and they work well together. I am now building a test oval with turnouts to test all the electronics before scaling it up to large layout. With the 3D printed block signals the out of pocket cost for a 3 Aspect block signal is ~$10 a 3 over 2 is ~$14 and a 2 aspect dwarf signal is ~$6. Replacing the RR-CirKits Signal LCC with a DIY LCC node would reduce the 3 and 3 over 2 block signals by ~$4. The cost does not include the wiring. Wiring a larger layout will require discipline. For most part I have enjoyed learning the electronics and software for a microprocessor controlled layout.

Attachments

@carl552 posted:The LCC network will do the track occupancy detection and control the signals, turnouts, lighting and accessories. Train Controller Gold will have access to the LCC network for occupancy information and to control turnouts and accessories. Computer operation of the layout by Train Controller requires the occupancy information and control of the turnouts.

It sounds like you are equal to the task. When you're finished, you ought to be able to stand back and watch your trains run automatically, and, additionally, bible to modify and maintain the whole layout. I hope you'll keep this thread going with updates.

I deleted my last reply as I goofed - LCS on the brain, I guess. I've used LCC on my modular layout. It reduces the complexity of wiring normally associated with mechanical relays. While I used it sparingly for signalling, it really shines for activating things. You can have multiple triggers, central control, train detectors, local push buttons, etc. All can connect to the bus via the boards mentioned above. Only the bus has to go around the whole layout. Works great for modular where you don't want bundles of wires traversing the joints of the modules. When I first started trying to reduce the amount of wiring, I used the MERG CBUS system. Same functionality as LCC.

Brendan