I'm guessing that, to use a Blunami 4408 decoder with 3 rail AC track power, a full-wave bridge rectifier is needed between the loco's track pickups and the Blunami power input connections, plus isolation of all load devices (lights, motors, couplers) from the loco chassis. Correct?

Replies sorted oldest to newest

Hi Karl, I have a Blunami board and it warns about things need to be isolated from the chassis. All your lights need to be directly connected to the screw terminals. It only states using DC or DCC for track power. Might be a good idea using a full wave rectifier. Or contact George at Soundtraxx.

Don

When not connected to their power source, lights, motors and couplers are isolated. Most early smoke units have a connection to chassis ground but the circuit can be cut to eliminate that. Newer Lionel smoke units are isolated. You will want to check couplers though to make sure no bare wires are touching metal. Many times when couplers open unexpectedly its due to wire shorting to ground in the coil.

Pete

As info DCC is AC on the rails. and the Blunami has a wide voltage range that it will except. I have used DCC on my two rail stuff for years , the decoders are compact motor driver and sound on one board and the range of features and sound quality are far better than most of the generic sounds that are in Lionel and MTH locos. and at about $205 street price not a bad deal. I plan on upgrading some of my older 3 rail stuff and adding command to some that is still conventional as well as a couple of MTH locos with toasted boards. the instruction and spec sheets are available on line.

Hmm. My question is, how sensitive is Blunami to the subtle changes in track voltage encountered in real-world layout conditions?

I've been considering a similar direct R/C technology made by AirWire. Their decoder was originally designed to work with an on-board battery (sometimes known as "dead rail.") The company warned me that the decoder should only be fed smoothed, regulated DC. In other words, the stuff Karl mentioned is needed to modify the track power, and trick it into thinking that it's being fed by a battery.

Perhaps Blunami is more tolerant of jagged waveforms, spikes, and voltage variations. If you want to risk letting the magic smoke out, you could try feeding it directly from the track. If the loco mysteriously speeds up or slows down on parts of your layout, then you would probably benefit from some kind of "helper circuit" consisting of a rectifier, capacitor, and maybe a Zener diode? or some other component(s) to regulate the voltage.

I'm not as excited about Blunami because I don't want to run my trains with a cell phone. (Direct R/C competitors AirWire and RailPro both offer hand-held controllers.) Given the issues with Legacy and DCS in the past year, all of these alternatives are worth considering! Good thread, following!!

Sufficient capacitance to approximate a battery isn't going to fit in most loco shells. But enough to take out the worst of the "trash" on the AC feed should fit. My controller would be an iPad. I will likely give this a try in a DCRU loco and see what happens. The flexibility of sound is attractive.

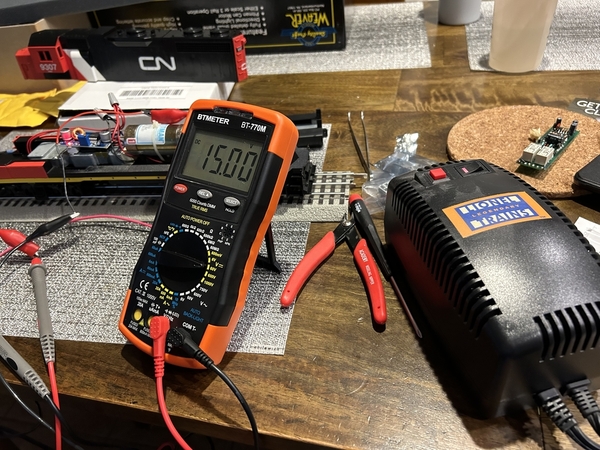

It appears that the Blunami will not work with unfiltered, rectified track AC. The open question is how much filtering (i.e., how big a filter capacitor) is needed to make the 120 Hz ripple tolerable. I'll get a Blunami board, bridge rectifier, grab some capacitors our of my inventory and find out. Weaver Baldwin Shark will be the guinea pig.

I asked them about running it on AC when they first announced these last summer and the answer I got was that you would need to do something between the track and the board. Ideally, according to Soundtrax, feed it 15V DC. Its on my list to fiddle around with one of these boards, a rectifier or some diodes and a weaver GP38 (which is fully insulated on a plastic frame), but I havent gotten that far down the list of things that need to be done at the moment.

Just got my Blunami a few days a go. Easy to setup the basics in a three rail steam engine. Has anyone paired a coupler release circuit (relay) on a function output to the coupler sound button. I am new to all this CV stuff. I want to press the coupler button on the app, hear the sound and open an electrocoupler like TMCC and DCS does.

Pete

Has anyone found a voltage converter that will fit in a hood unit and withstand the amp limit of the decoder? I got a board on eBay that’s good for 5A, but it’s too big to fit in a narrow hood. Probably fine for a full width locomotive or a tender though. I just need one with a smaller form factor. If anyone has found one, let me know something about it.

Attachments

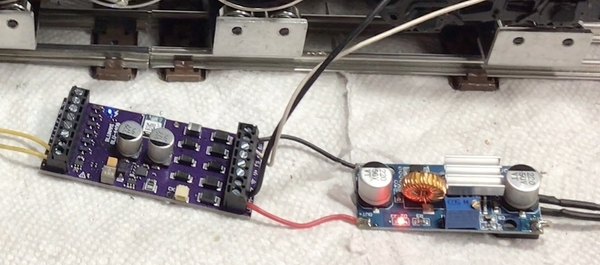

This just came in the mail from Amazon. It is 2" Long by 1" wide. I bought it for another use.

Haven't messed with it yet, but it is only rated for 3A.

https://www.amazon.com/dp/B09F...dt_b_product_details

John

@Norton posted:

Thanks Pete.

I sent you an email....

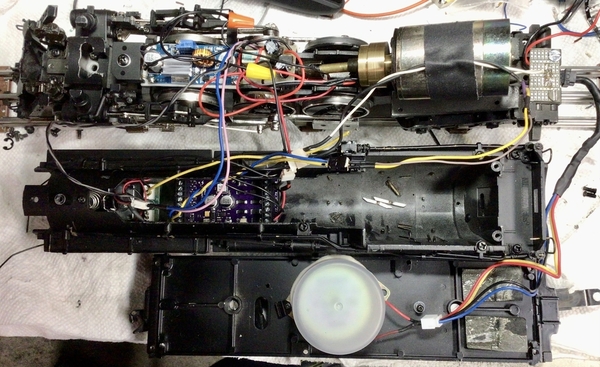

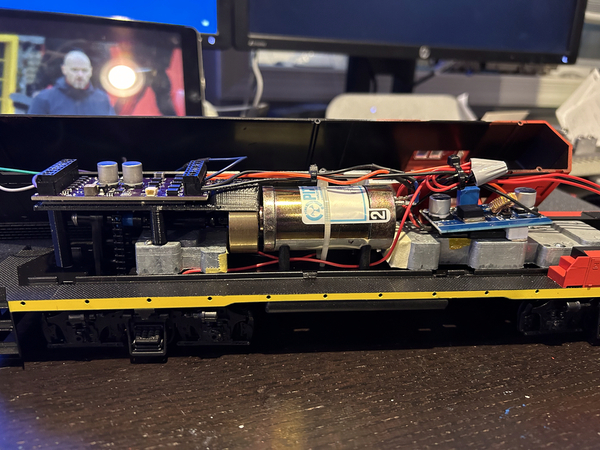

I am literally in the process of stuffing some boards in this engine. The buck convertor requires a full wave bridge if you want to power it off the three rail track. I had a 6 amp bridge thats attached to the convertor. The Blunmi was too wide to mount on the chassis so I had to place it in the shell requiring many more connectors for servicing. Next step is to see how well it receives signal in the diecast shell. If not well plan B is to mount it in the tender.

Pete

Attachments

@Boilermaker1 I'm concerned that even if you find a converter with a narrower form factor, the heat radiating off your heat sink would warp your plastic shell. I would imagine that it HAS to be firmly in contact with the metal chassis.

Most of you have seen my rants about rubber tires in 3-rail O gauge. Ask yourself: What would the peak current draw be if the wheels were allowed to slip, as God and Sir Isaac Newton intended? Perhaps 3A is sufficient?

@Ted S posted:@Boilermaker1 I'm concerned that even if you find a converter with a narrower form factor, the heat radiating off your heat sink would warp your plastic shell. I would imagine that it HAS to be firmly in contact with the metal chassis.

Most of you have seen my rants about rubber tires in 3-rail O gauge. Ask yourself: What would the peak current draw be if the wheels were allowed to slip, as God and Sir Isaac Newton intended? Perhaps 3A is sufficient?

Ted, these are switching regulators, not linear regulators. They are much more efficient. Running that big Pittman the heat sink is barely above ambient.

Pete

@Ted S posted:@Boilermaker1 I'm concerned that even if you find a converter with a narrower form factor, the heat radiating off your heat sink would warp your plastic shell. I would imagine that it HAS to be firmly in contact with the metal chassis.

Most of you have seen my rants about rubber tires in 3-rail O gauge. Ask yourself: What would the peak current draw be if the wheels were allowed to slip, as God and Sir Isaac Newton intended? Perhaps 3A is sufficient?

The peak current draw is not at wheel slip, which is essentially a no load condition. The current peaks when the motor stalls and the stall current is easy to measure with a meter by simply holding the output shaft of the motor and turning the voltage wide open.

It’s a 4 amp decoder. Need to be able to supply at least that much power to it. Soundtraxx decoders have a fail safe that will shut the decoder down if the motor driver overloads to save the decoder.

Not worried about heat, it’s not that much power, and there’s already primitive electronics in there that haven’t melted down.

Yes, it's true that current draw at stall will be much higher than with the wheels slipping. What I meant is that if your diesel didn't have rubber tires on its wheels (and you also didn't purposely add extra weight), wheelslip would occur long before stall current reached 5A. Especially if you were to rewire the twin motors in series.

I guess the decoder's overload protection is a good thing, otherwise you would have to consciously limit the train length to prevent accidentally exceeding the current rating.

My p/o/v is that the motor driver should be able to handle the stall current of the motor(s) and that the DC power source for said driver should be capable of delivering that current, plus the "overhead" load of the controlling electronics, without significant voltage loss and excessive 120 Hz ripple. I don't yet have a bench DC supply capable of testing the motors accurately, but suspect that a pair of can motors in a typical loco, wired in series, will not overload the Blunami board under "normal" operating conditions. The series connection should be OK if the loco is geared to run at excessive speed with 16+ V supplied to it, in "conventional" mode. A large can motor in a large steamer is another matter.

@Boilermaker1 posted:Thanks Pete.

I sent you an email....

Good evening -- could one of you post the link to this device? Thank you...

OK, here is the first test run of this MTH Hudson, former parts donor with a Williams tender. Motor is a 9433 Pittman, Lionel dumb fan smoke unit, 50 mm Fatboy speaker, main volume at about 50% and a Blunami 4408. AC to DC using a 5 amp switching convertor and 6 amp bridge rectifier. Added cost under 5 bucks. Amp draw according to my MTH Z4000 is under 1 amp.

Pete

Attachments

Awesome Work Pete. That project deserves it’s own thread. I’ve been trying my best to follow along with this and learn more about it. After watching the video. It certainly runs smooth. Is there any sort of cruise feature involved ?

Can it run with a TMCC or DCS running on the same block of track ?

Dave, your post reminded me I wanted to try that so just did. Put a MTH detector engine, and a TMCC Hudson all on the same track. No problem running them all at once. Too bad I only have a test track and could only run them a few feet.

The basic install is actually pretty simple. Add a AC to DC supply and you can have a running engine with sounds and lights in 20 minutes. Not much harder than installing a E unit. Its the add ons that take time. Not many in the DCC world use electro couplers and not sure many more have working smoke so the Blunami doesn’t provide that directly. Intermediate circuits have to be added to do that.

Where these shine is the sound selection. Legacy now has 5 whistles. This has 90. Plus choices on most all the other sounds, bell, coupler, dynamo, etc. The other place they excel is being able to add your own features to an engine and label them accordingly in the control panel.

It has Back EMF and runs fairly steady but you can see in the video that it sped up after uncoupling the train. Still low speed is fairly slow and steady.

I don’t expect this to replace ERR or PS3 kits until they disappear but if they do this is one way to keep them running and with all the features plus more than Legacy. Maybe a cottage industry will spring up to make those add ons for those that can’t design and fabricate their own.

Pete

I got it working. Thanks to @Norton for the help with the voltage conversion. I just need to “install” it now.

Bit of a tight fit with the horizontal motor, the decoder is gonna have to go above the rear drive tower and the speaker in the roof of the shell.

Parts:

Bridge : https://www.amazon.com/gp/aw/d...pop_mob_b_asin_title

Voltage converter: https://www.amazon.com/gp/aw/d...pop_mob_b_asin_title

Blunami 4408 EMD Diesel (885617)

Speaker is a 40x28mm 8ohm 4w from streamlined backshop.

Attachments

@Boilermaker1 -- Thank you for posting the parts list. I am hoping to use these boards in some installs of my own, and it is very helpful.

The DC>DC buck converter is available for $5½ on the biggest auction site. I ordered a pair for evaluation.

Wow....you guys are fantastic!! Just discovered these Blunami decoders yesterday at the Cartersville Train show 3-11-23 thru 3-12-23.

I just did a test of the range of the Blunami. Mine is now mounted in the engine shell. In that location I was only able to connect and blow the whistle from maybe 25 feet. That included one wood wall and then again one floor over the track. Then removed the shell and flipped it bottom side up. I could connect to it from over 40 feet one floor up. I ran out of room but would expect range is better than that on an open layout.

Conclusion, diecast greatly attenuates the signal. Mine will get moved to the tender with its plastic coal load.

Pete

http://bluerailtrains.com/runn...rail-ac-track-power/

Nice write up on what is required to use Blunami with 3 Rail AC power.

@Norton posted:OK, here is the first test run of this MTH Hudson, former parts donor with a Williams tender. Motor is a 9433 Pittman, Lionel dumb fan smoke unit, 50 mm Fatboy speaker, main volume at about 50% and a Blunami 4408. AC to DC using a 5 amp switching convertor and 6 amp bridge rectifier. Added cost under 5 bucks. Amp draw according to my MTH Z4000 is under 1 amp.

Pete

Smooth running, but the chuff sound doesn't impress me.

@Mad_Liver posted:http://bluerailtrains.com/runn...rail-ac-track-power/

Nice write up on what is required to use Blunami with 3 Rail AC power.

That would not be appropriate for either the 2 amp or 4 amp Blunami. Those three terminal regulators are only spec’ed at 1 amp. Plus its a linear regulator which is why it needs the big heat sink. That article was likely meant for a smaller decoder.

Pete

@gunrunnerjohn posted:Smooth running, but the chuff sound doesn't impress me.

I agree its not as rich as a Railsounds 4 chuff. There are some ways to modify the sound but I haven’t got to those yet. I can say it is deeper than what my iPad mike is picking up but too abrupt for my taste.

Pete

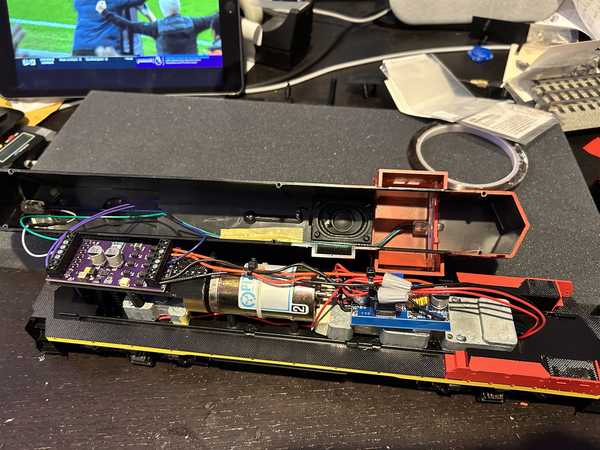

Ok... finished.

I 3D printed a shelf for the decoder to sit above the drive tower, and a box for the speaker to sit in. This is a "temporarily permanent" install. I dont really like using 2 sided tape to do stuff, but I did here. This was a "science project". This loco was a $90 York score, and it needs to be repainted into something a bit less Canadian (not to mention the road number is inaccurate).

I just have it running on rollers at the moment as the part of my layout that has a center rail is inoperable at the moment, but I'll find a place to go play with it soon. It connected and ran fine on both my phone and my ipad. Doesnt seem to have issues swapping back and forth between devices, but only one connection at a time it seems.

This was my first time installing a Tsunami 44XX board. I have a few Red Caboose GP9s running on 2200 boards, but the rest of my DCC stuff is Loksound 5Ls. Jury still out on the screw terminals. I do like that you can solder on the loksound boards in any direction, whereas the screw terminals force you to sometimes wrap wires around the back side and in, but it does make it easier for "anyone" to install it. With the voltage converter work needed, its not a solderless install. I also put sunny white LEDs in the lights, which needed 1K ohm resistors for the decoder to not blow them up.

A 6A bridge is under the blue board, which is the voltage converter. Its screwed to the diecast weight for a heat sink. The voltage converter is set to put out 16V DC (I bumped it up a volt from the pic above).

The Blunami board mount is just a flat plate with some posts. The rear post is screwed in through the frame. The front 2 posts just sit in some holes that were already in the weight. There's a rounded hood for the flywheel to keep the wiring away from it.

Stuffing the speaker in the air filter box in the roof meant I had to add a few holes to the shell and run the speaker wires through the dynamic brake pocket in the shell. Cant see it, no big deal here.

The interface resizes itself for an iPad.

Just playing around.... It will take some time playing with the CVs to get it all to run well. First thing I did though was set the Accel to 120 and the Decel to 80. Thats what I use in all my other locos. Equate it to TMCC momentum settings.

In total: $205 board, $.60 bridge, $6 voltage converter and a $10 speaker. I dont calculate the price of 3D printer filament because the 2m it took is pennies. So $222 in the locomotive. About the same as a PS3 upgrade, and way cheaper than a ERR set. Tons of sounds, nearly infinite adjustment, people may start realizing what they were missing out on with these proprietary systems.

One thing though: Don't stock pile these decoders for installs. Buy them as you need them. These are V1.0, it would not surprise me if they end up adding tweaks , adding/changing sound files or advancing with bluetooth parts, etc... to V1.1 and so on, and the firmware boards isnt "upgradable" like a Loksound board is. Just install the version you can buy at the time and buy another board for the next install. They'll still play with each other because its all DCC, but you'll kick yourself if they upgrade the sound fidelity and you've got a stack of old ones.

Attachments

@Norton posted:I agree its not as rich as a Railsounds 4 chuff. There are some ways to modify the sound but I haven’t got to those yet. I can say it is deeper than what my iPad mike is picking up but too abrupt for my taste.

Pete

I figured there had to be better options. I think the abrupt nature is the most obnoxious, it's just sort of a static burst, hearkens back to the Mighty Sound of Steam. ![]()

@gunrunnerjohn posted:I figured there had to be better options. I think the abrupt nature is the most obnoxious, it's just sort of a static burst, hearkens back to the Mighty Sound of Steam.

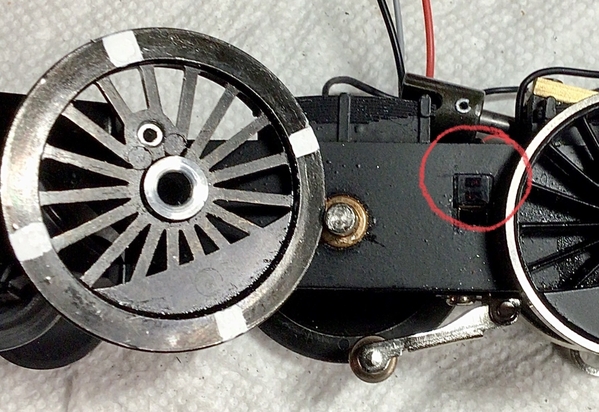

The bigger problem with the chuff is you can’t synchronize chuff with puff. Some Soundtraxx boards have a cam in to do that. Blunami doesn’t. The smoke fan here is driven off an optical detector with stripes on a driver. Perfect 4 puffs per rev but it doesn’t always align with the chuff sound. You can adjust the sound to be close to driver rotation like you can with EOB (kit version) or DCS tach strips, there is a variable on the configuration page, but it doesn’t always start at the same place so sometimes you get smoke puffs in between chuffs.

Hopefully that will be addressed in future versions or maybe another manufacturer will get on the Bluetooth DCC band wagon. Still a lot of potential here especially for do it yourselfers.

Pete

Is there any way to supply the chuff yourself? That to me would be a major issue for me if the chuff sound didn't match the chuff smoke! In looking at the decoder wiring, I don't even see how you connect a smoke unit. I'm presuming you use a couple of the functions that illustrate lamps for the smoke instead?

Attachments

There are no specific outputs for a smoke unit. I am using one output to drive a relay (outputs can only supply 100ma, so a relay is required for larger current draws) that turns power on and off to the smoke unit but the fan is driven by the optical detector circuit. I would typically use a cam and micro switch but not easy on an MTH engine with enclosed axles. Of course I suspect most others would use your chuff generator.

Maybe other DCC users here can comment on the cam feature on other Soundtraxx decoders. I am just a rookie here with this DCC stuff.

My chuff switch.

Pete

Attachments

Yikes, pulling the wheel off would turn a lot of folks off. ![]() The latest shipping version of the Chuff-Generator has a FET driver for the chuff, so it could easily drive the motor directly

The latest shipping version of the Chuff-Generator has a FET driver for the chuff, so it could easily drive the motor directly

The lack of synchronization is still problematic, I guess that's in the next generation. I wonder how other decoders do it, I have seen HO steamers with synchronized smoke.

@Norton posted:That would not be appropriate for either the 2 amp or 4 amp Blunami. Those three terminal regulators are only spec’ed at 1 amp. Plus its a linear regulator which is why it needs the big heat sink. That article was likely meant for a smaller decoder.

Pete

I was just going off what Blunami sent me.