John,

From what I've seen, it's the battery that's preventing BPRC from really taking off.

The Receiver/ESC module, the on/off module, and charging jack could all be all be combined on one small circuit board, I would think for less than the going price (<$100) now. The batteries I've used so far (11.1 Lipo and 9.6 NiMh) are approx the same size (1"x1-3/8"x4-1/8"), they make a 12v, 1400Mah, NiMh that is 2.3"x1.3"x1.1" but were out of them last time I checked. I think the 1400Mah would be fine, maybe could go even less and still get an hour or 2 run time.

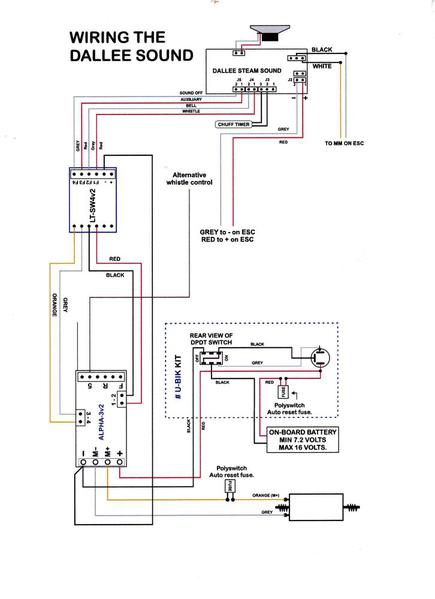

I'm doing my 4th conversion today (Williams brass 2-8-2) and feel with every installation I'm learning how to make things smaller and fit better (wiring can be a PITA, always in the way), maybe if all the components were on 1 board most of the wiring would disappear. Next up is a 4-6-0 I scratchbuilt using a Weaver chassis and the brass tender from the 2-8-2.

I'm using the 10-pin connectors found on MTH steamers with the straight 10-pin wiring harness. So far all I've wired in is the motor, headlight, and backup light (2 of my engines don't have backup lights, strange but the photos I have of the real one didn't show them).

I had to go to the local RC shop this morning to get some extension cables with Deans connectors and noticed they have a lot of small battery packs that may be the answer I'm looking for.

Of all the things, the battery size is the one drawback. Sound is the other, but I can take it or leave it. No smoke but I took all mine out a while back. I'm sure it could be sued, these kits are being used in G scale engines with smoke.

On the plus side:

No more expensive transformers and all the command stuff between it and the track

No more track wiring

No more cleaning track

No more worries about short circuits on the track

Still need power to control any switches and things like a turntable, I'm using wallwarts for power now

I could wire in class lights, marker lights, etc but the more I read on how the real ones were used the more I think I don't need them for running a train on the main and one switching.

Anyhoo, I'm having fun