In this multi-part post I'll take you along the adventure of building a Locomotive Workshop's E9 kit. Interest in building a locomotive kit occurred after I signed up to be a digital subscriber to O Gauge Magazine. Alan Arnold has given us access to an incredible research tool and I would recommend all forum members sign-up to be an OGR digital subscriber. I began reading these early OSR magazines cover-to-cover to learn more about our hobby. Starting at issue #1, I learned of the different obstacles facing model railroad hobbyists at the time. It seems during the late 60’s and early 70’s O scale trains were going through rough time. The HO train market was getting huge and taking over the hobby. There wasn’t a lot of O scale manufactures at the time and only a few of them made scale locomotives. 50 years ago if somebody in our hobby wanted a true "scale sized" diesel locomotive in a specific style or paint scheme, they had to build it.

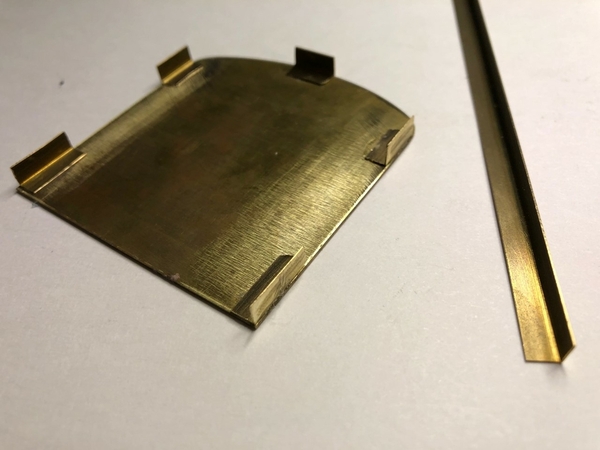

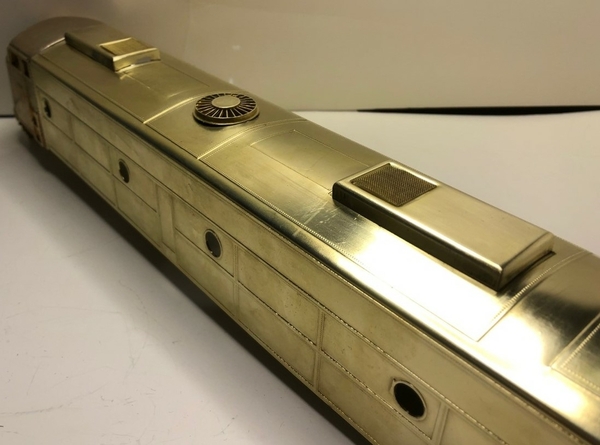

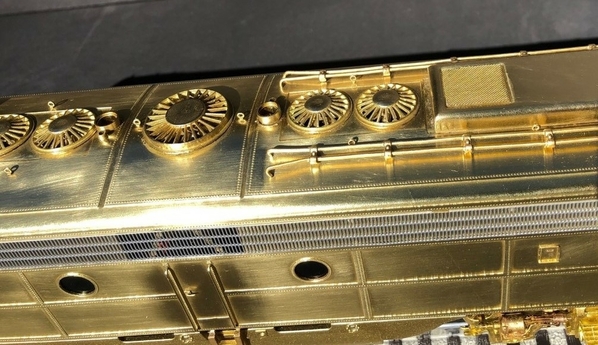

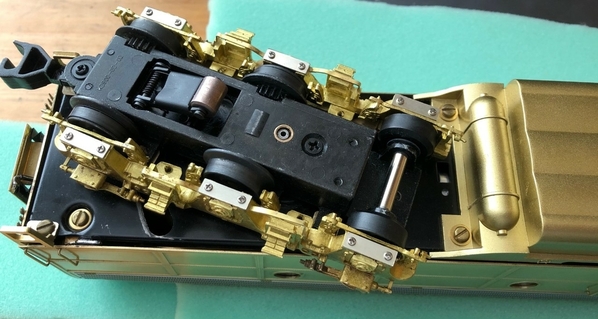

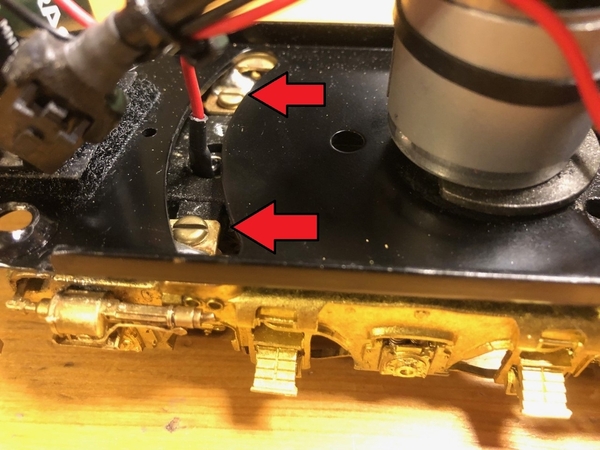

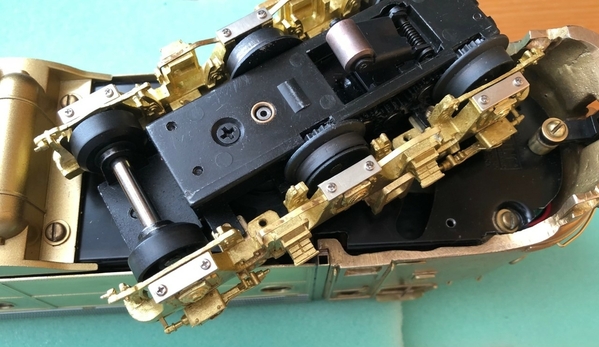

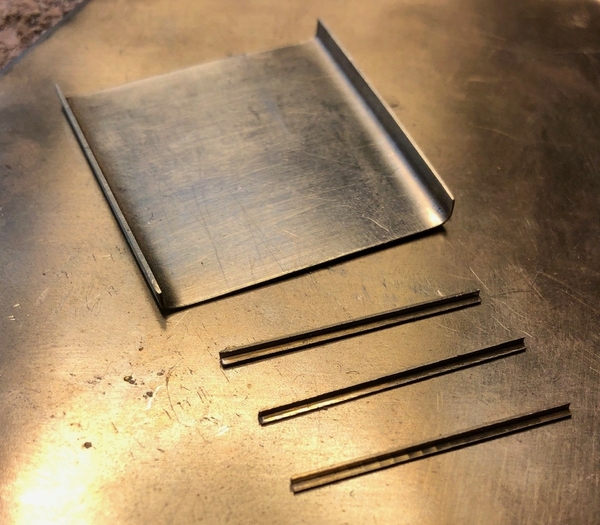

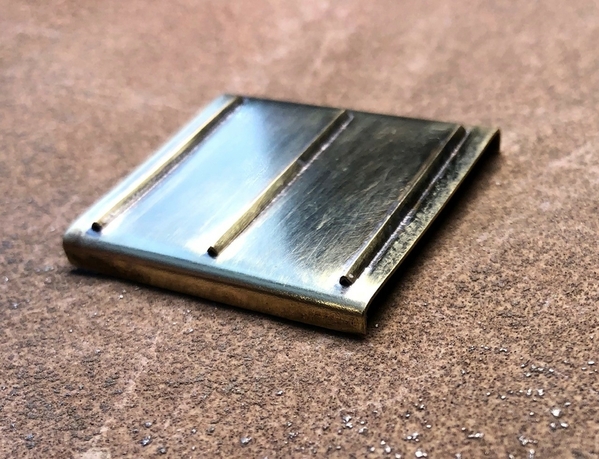

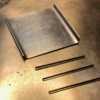

By the time I hit OSR magazine issue #14, I read an advertisement that stated Locomotive Workshop was going to have an E9 diesel kit available in the near future for $59.50. The ad's description read: The E9 kit was sold basically complete except for the mechanism. Includes basic body and soft metal trucks. Brass engraved - photo engraved brass - brass photo etched body. The nose section on this E9 kit was a lost wax brass casting.

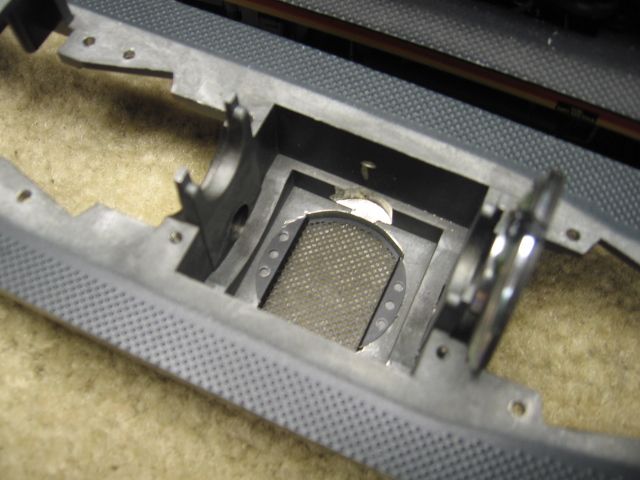

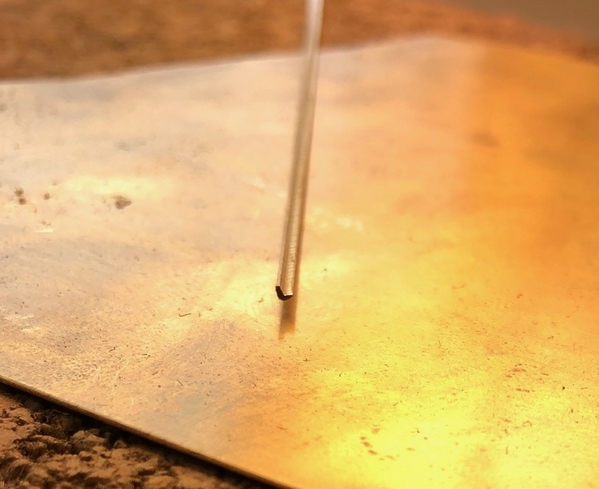

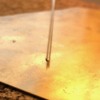

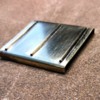

For me, building an unassembled locomotive from a kit was a completely different aspect of the model railroading hobby. Ok then... I was willing to give it a try. Looking online I found an unbuilt Locomotive Workshop E9 kit for sale and clicked Buy-Now. The kit arrived at my house a few days later. Here's what the parts look like laid out across a table.

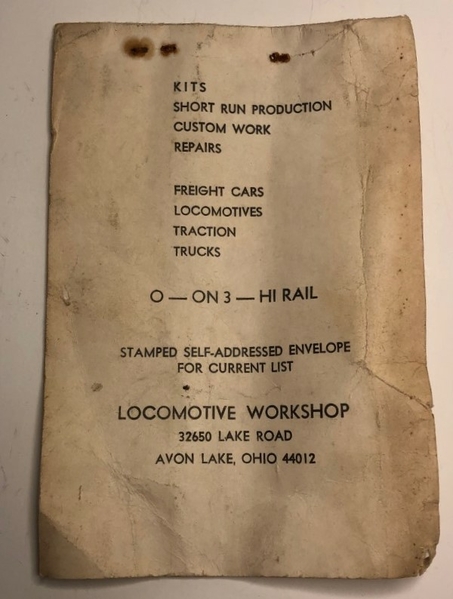

The literature that came with this kit said it could be built as O – ON3 – Hi Rail. I decided to try and build this E9 diesel locomotive for Hi-Rail so it can run on my layout. An article in the OSR magazine mentioned they made small production runs of only 25 to 30 units at a time and shipped orders from this inventory. The business location on the original shipping label and all paperwork included in the box showed Avon Lake, Ohio. That’s interesting because Locomotive Workshop's mailing address changed in the January 1973 issue #31 of OSR issue to Englishtown New Jersey. At this point all clues showed this E9 kit was pre-January 1973 inventory and probably from the first production run in 1971.

The best I could figure, the original owner paid $59.50 for this kit. That would calculate to around $399.00 in today’s dollars. That seems like A LOT of money today for an unbuilt kit. But times were different back in 1971 and building a kit was the only way they had to get the exact diesel locomotive they wanted.

Click the like button below to follow this thread and stay tuned for the next update in this adventure.