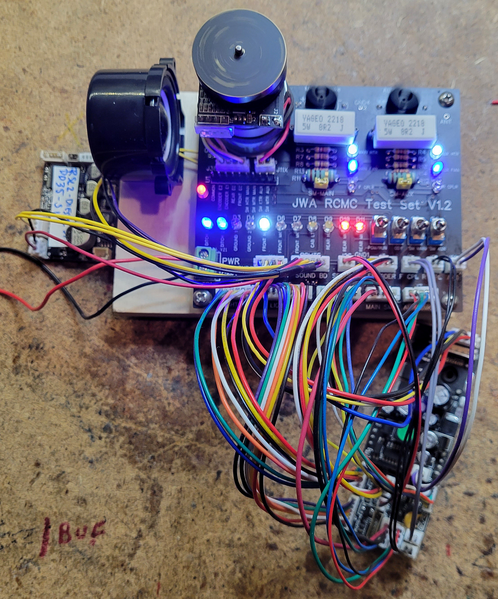

I've been thinking about this project for some time, but I finally got around to knocking it out. This is an RCMC Test Fixture that is designed to test all the functions of either of the two first versions of the RCMC. Those versions span from 2010 to 2019, I haven't looked at the latest version requirements.

Here's a plan view of the PCB that allows you to read the graphics more clearly.

<click on graphic to expand>

The Legacy motor with encoder is mounted on the board with connections for the motor and encoder provided. Two complete simulated smoke units are provided with real smoke motors as some of the RCMC versions detect back-EMF and require a real motor to avoid an error shutdown. All the lighting outputs are represented with individual LED's. LED are color coded for quick recognition, red for rear markers, green for front markers, blue for ditch lights, amber for ground lights, etc. Couplers are simulated by resistors as well. Both the smoke unit functions and couplers have LED function indicators to provide visual feedback of operation. A header is provided to connect a RailSounds Lite audio board, that facilitates operation evaluation as sounds are an important feedback for board operation.

A ten position header is provided with 'scope probe points to many of the most common functions that you might like to electronically monitor.

The test set has cables for both versions of the RCMC, with and without smoke thermistors. That is required as some of the connectors changed sizes when the thermistor version was introduced.