I have the above locomotive, I need to change all of the tires on the front and rear sets of drivers. Is there anything I should be aware of before I tackle it? How hard is it to change these out? I'm really nervous about this as I don't want to mess something up and have it become a Shelf Queen as I'm not really hankering to send it back to Lionel for this task. This is the TMCC version and I really like it, I may have it converted over to Legacy in the near future. Thanks for your help it will truly be appreciated. I read the little book that came with it but it didn't make me feel to good about having to change them out but it has to be done.

Replies sorted oldest to newest

@J. Motts posted:I have the above locomotive, I need to change all of the tires on the front and rear sets of drivers. Is there anything I should be aware of before I tackle it? How hard is it to change these out? I'm really nervous about this as I don't want to mess something up and have it become a Shelf Queen as I'm not really hankering to send it back to Lionel for this task. This is the TMCC version and I really like it, I may have it converted over to Legacy in the near future. Thanks for your help it will truly be appreciated. I read the little book that came with it but it didn't make me feel to good about having to change them out but it has to be done.

If you're not familiar with how to properly re-position the eccentric crank to the correct (quarter) lock-in position after reassembling the drive rods - I'd hand her over to a trustworthy tech. It’s all too easy on a Challenger to lose the original placement of the eccentric crank and then put it all back on slightly incorrectly and end up with damaged rods attempting to run.

If you're on the east coast - take your pick, there are a number of skilled guys your way that this would be a cake-walk for if you’re not comfortable with doing it.

If you're on the west or want to send it my way feel free to get in touch directly via my profile info. I've done dozens of them.

@DdotCdot posted:If you're not familiar with how to properly re-quarter drive rods - I'd hand her over to a trustworthy tech.

There's no quartering involved in removing the rods! Quartering in the relationship between the left and drivers on a single axle, and it would only be altered by pulling a wheel off the axle!

@J. Motts posted:I have the above locomotive, I need to change all of the tires on the front and rear sets of drivers. Is there anything I should be aware of before I tackle it? How hard is it to change these out?

Not hard at all. The tries are on the rear axle of each power truck. You just have to remove the one screw and note where the spacers are, pictures are useful.

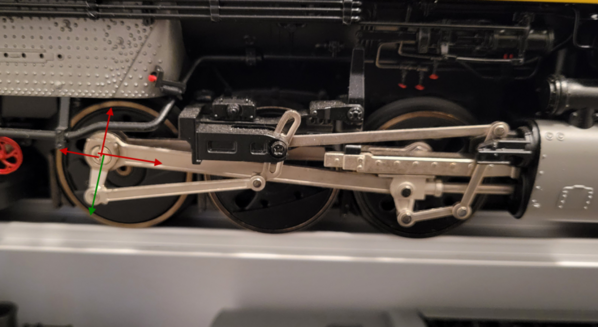

The one point of caution is getting the eccentric crank back on the wheel in the correct orientation, it fit into the wheel notches in four different places. Again, take a picture before you disassemble it, and make it match the picture. FYI, the eccentric crank should point inward near the axle. It's possible to put the eccentric on in any of four orientations, see below. The green arrow is the correct orientation, note it points close to the axle. The other orientations indicated by the red arrows are the wrong way and will result in lockups.

Click graphic to enlarge

Attachments

Are we talking tires as in "rims", or tires as in "traction"? I thought "TT"...I think GRJ is thinking "traction tires" as well...(?)

Mark in Oregon

@gunrunnerjohn posted:There's no quartering involved in removing the rods! Quartering in the relationship between the left and drivers on a single axle, and it would only be altered by pulling a wheel off the axle!

Not hard at all. The tries are on the rear axle of each power truck. You just have to remove the one screw and note where the spacers are, pictures are useful.

The one point of caution is getting the eccentric crank back on the wheel in the correct orientation, it fit into the wheel notches in four different places. Again, take a picture before you disassemble it, and make it match the picture. FYI, the eccentric crank should point inward near the axle. It's possible to put the eccentric on in any of four orientations, see below. The green arrow is the correct orientation, note it points close to the axle. The other orientations indicated by the red arrows are the wrong way and will result in lockups.

Click graphic to enlarge

I’ve revised my note to more clearly reflect we are essentially warning against the same potential disaster outcome here common to a non-repair person on locomotives like this one.

Easy as this may be for me and for you, I stand by my recommendation to the OP as what’s in his best interest for this particular model based on what he wrote.

If this was a Vision or 2019 Big Boy, I’d say go for it. Even the JLC Big Boy had an odd configuration with the rear driver set that makes it a tricky one to do tires on. If I remember right - the front most wheels on the rear driver set are slotted, but not the rearmost wheels like later models (which is much easier). The drive rod guide gets in the way of that one.

@DdotCdot posted:Easy as this may be for me and for you, I stand by my recommendation to the OP as what’s in his best interest for this particular model based on what he wrote.

You're certainly free to have your belief as to what is and isn't possible for a novice to do. I happen to believe that the OP can successfully install traction tires on this locomotive with a little guidance. There is nothing magical about changing these tires, a little care and direction and he can save him a chunk of cash and also gain a small amount of maintenance wisdom in the process.

@gunrunnerjohn posted:You're certainly free to have your belief as to what is and isn't possible for a novice to do. I happen to believe that the OP can successfully install traction tires on this locomotive with a little guidance. There is nothing magical about changing these tires, a little care and direction and he can save him a chunk of cash and also gain a small amount of maintenance wisdom in the process.

@J. Motts posted:I have the above locomotive, I need to change all of the tires on the front and rear sets of drivers. Is there anything I should be aware of before I tackle it? How hard is it to change these out? I'm really nervous about this as I don't want to mess something up and have it become a Shelf Queen as I'm not really hankering to send it back to Lionel for this task. This is the TMCC version and I really like it, I may have it converted over to Legacy in the near future. Thanks for your help it will truly be appreciated. I read the little book that came with it but it didn't make me feel to good about having to change them out but it has to be done.

J.Motts - if you decide to tackle it with some care and patience it can be done, and I hope it will be a satisfying experience for you.

If you decide to ease your nerves and let someone else handle it there’s absolutely no shame in that either. You have to go with the decision you’re comfortable with. There’s no wrong decision here, so long as you’re not uncomfortable.

Please know, despite what someone else might have you think, I do not believe you are a “novice” and would never imply such an outrageous assumption when trying to help anyone here reaching out to other experienced members for advice.

All the best.

@DdotCdot posted:Please know, despite what someone else might have you think, I do not believe you are a “novice” and would never imply such an outrageous assumption when trying to help anyone here reaching out to other experienced members for advice.

Really? You want to go there? ![]() You're the one that insinuated that he would be unable to do the job!

You're the one that insinuated that he would be unable to do the job! ![]()

I just changed all 4 tires on my JLC Challenger, so here are some pointers:

The tires are all on the last drivers on each engine set, so you'll have to take the screw out that holds the main rod and eccentric on all the wheels with tires. There's enough slack to lift all the rods up and slip the tire under.

The rear engine has the last wheel set right up near the firebox. You'll need a couple pics or small screwdrivers to help guide the tires on.

Remove the brake details near the tire you're working on to get the tire on easier.

Make sure you put the eccentric back how you found it. Take a picture so you put it back how it was when you removed it.

All in all it's an easy job. Hardest part is getting the new tires on straight. Should take you maybe 10 minutes or so to do.

@gunrunnerjohn posted:Really? You want to go there?

You're the one that insinuated that he would be unable to do the job!

No, I simply gave him my advice after he mentioned being nervous about doing the job, which I can respect on this locomotive if one has never worked on it before. Pure and simple. You jumped on this thing throwing shade my way from the start. Over and out.

@Lou1985 posted:Remove the brake details near the tire you're working on to get the tire on easier.

Good tip on the brake shoes, I usually remove those but I forgot to mention it. ![]()

Morning Guys, thank you all for your great responses from all of you, I'm going to go ahead and get after it within the next couple of days this week. I should be able to do this, I have plenty of mechanical ability to do the job, its just that sometimes my confidence goes down a bit when I start thinking about how much I paid for it and what happens if I lose something or just do something wrong and can't fix it, then I'll have to send it out to get it fixed. It just looks overwhelming when you first start looking and thinking about it.

DdotCdot, thanks for your advice, it is well taken but as I was looking at it over the other day, I got to thinking, if I don't do it, I'll never know if I could do it or not. I will tackle it this week and report back to you all on how I did.

GRJ, thanks for the great pic, I've already saved it and will print it out before starting work, plus I'll shoot a bunch more as I go along. Your tips will come in handy and thanks also for giving me a little push to go ahead and give it a try.

Mark, thanks for your response, yes I was talking about changing the traction tires on my locomotive, I don't think I'm up for pulling a driver tire off of an axel just yet, besides I don't have the necessary tools yet to be able to do it successfully, but I'm working on it.

Lou1985, thank you for the great set of instructions on how to get it done. I have read it about 3 or 4 times already and between everyone, I'm up for the task and ready to tackle the job. As for pictures, I've always used them, my late father was a Master Machinist and worked for the Bendix Corp back before WWII in South Bend, Indiana. When I got old enough to start working on things, he told me to draw a sketch or picture of what I was working on and to jot down how I took it apart and make a list of how I was doing the job so I could put it back together the same way I took it apart. I've always done this as to how he taught me, that is where my mechanical ability and background came from. When the cell phones with cameras came about, I used that feature like crazy and will always do it. When I worked as a locksmith back in El Paso, I took pictures of locks every time I got ready to tear one apart, same thing on safes and their dials. God Bless the person who came up with the idea to put a camera on the phones. He/she probably has no idea how much this helped guys like us to do this kind of stuff.

So again guys, thanks for the great advice, the great pictures and the great tutorial to get me off the hump and get going. I'll report back after I'm done, I'll either be a Happy Camper or a complete dofus.

Cheers!

@J. Motts posted:Morning Guys, thank you all for your great responses from all of you, I'm going to go ahead and get after it within the next couple of days this week. I should be able to do this, I have plenty of mechanical ability to do the job, its just that sometimes my confidence goes down a bit when I start thinking about how much I paid for it and what happens if I lose something or just do something wrong and can't fix it, then I'll have to send it out to get it fixed. It just looks overwhelming when you first start looking and thinking about it.

DdotCdot, thanks for your advice, it is well taken but as I was looking at it over the other day, I got to thinking, if I don't do it, I'll never know if I could do it or not. I will tackle it this week and report back to you all on how I did.

GRJ, thanks for the great pic, I've already saved it and will print it out before starting work, plus I'll shoot a bunch more as I go along. Your tips will come in handy and thanks also for giving me a little push to go ahead and give it a try.

Mark, thanks for your response, yes I was talking about changing the traction tires on my locomotive, I don't think I'm up for pulling a driver tire off of an axel just yet, besides I don't have the necessary tools yet to be able to do it successfully, but I'm working on it.

Lou1985, thank you for the great set of instructions on how to get it done. I have read it about 3 or 4 times already and between everyone, I'm up for the task and ready to tackle the job. As for pictures, I've always used them, my late father was a Master Machinist and worked for the Bendix Corp back before WWII in South Bend, Indiana. When I got old enough to start working on things, he told me to draw a sketch or picture of what I was working on and to jot down how I took it apart and make a list of how I was doing the job so I could put it back together the same way I took it apart. I've always done this as to how he taught me, that is where my mechanical ability and background came from. When the cell phones with cameras came about, I used that feature like crazy and will always do it. When I worked as a locksmith back in El Paso, I took pictures of locks every time I got ready to tear one apart, same thing on safes and their dials. God Bless the person who came up with the idea to put a camera on the phones. He/she probably has no idea how much this helped guys like us to do this kind of stuff.So again guys, thanks for the great advice, the great pictures and the great tutorial to get me off the hump and get going. I'll report back after I'm done, I'll either be a Happy Camper or a complete dofus.

Cheers!

Right on. I’m glad you found the confidence to give it a shot. GRJ’s vivid picture diagram does look like a very helpful reference guide there so I’m sure it will all go well for you. Lou1985 absolutely nailed it with the breakdown, especially the part about removing the brake details to get more access (I miss that ability on some of the newer models with delicate fixed or molded-in brake details). Very helpful tip.

Absolutely agree on the usefulness of phone cameras for keeping stuff straight with repair. Calling back reference photos has saved me many many times.

Cheers.

-D

Thanks D, I appreciate it.

Quick question guys, what do you all think it would cost to upgrade from the TMCC to Legacy?

Talk to @Bruk here, he does Legacy conversions. I actually had him do one, I went deluxe. I now have the JLC Challenger with all the Vision Line features, whistle smoke, dynamo, dual sound systems, etc.

@gunrunnerjohn posted:Talk to @Bruk here, he does Legacy conversions. I actually had him do one, I went deluxe. I now have the JLC Challenger with all the Vision Line features, whistle smoke, dynamo, dual sound systems, etc.

Ill make note that John's JLC Challenger will be the only one to get the dynamo and injector steam....Anyone one else that wants this done will only get the addition of whistle steam feature. As you cans see in this video of a recent conversion.

@Bruk posted:Ill make note that John's JLC Challenger will be the only one to get the dynamo and injector steam....Anyone one else that wants this done will only get the addition of whistle steam feature. As you cans see in this video of a recent conversion.

@gunrunnerjohn Thanks for ruining it for the rest of us.![]()

J.Motts, pick you up a nice set of dental pick tools, these are indispensable for tire changing, ….i conned my dentist into giving me a handful, but there’s cheap sets all over the popular auction sites from overseas suppliers,….some as little as 7 bucks for a set,….the spoon type are my favorite, and I call them my tire irons…..these make tire swaps a breeze …..I avoid the really sharp pointy ones, I don’t want a flat …..🤣🤣🤣

J.Motts, pick you up a nice set of dental pick tools, these are indispensable for tire changing, ….i conned my dentist into giving me a handful, but there’s cheap sets all over the popular auction sites from overseas suppliers,….some as little as 7 bucks for a set,….the spoon type are my favorite, and I call them my tire irons…..these make tire swaps a breeze …..I avoid the really sharp pointy ones, I don’t want a flat …..🤣🤣🤣

Pat

Attachments

I just use really small flat blade screwdrivers to change tires. Easy peasy.

@Lou1985 posted:I just use really small flat blade screwdrivers to change tires. Easy peasy.

Blunt tools, or rounded tools, reduce the risk of scratching or gouging delicate surfaces, The variety of different picks opens a lot of options for fiddling a tire into position……..I’m sure you do fine given the amount of tires you swap, but for the occasional tire swapper, the round end picks can prevent a lot heartache…..

Pat

@Bruk that was a really nice job you did on that Challenger and I want to thank GRJ for recommending you to me. I'll be in touch in the very near future.

Pat and Lou1985, I've got a good amount of dental pics and screwdrivers, in fact I have a boat load of tools for working on my trains and also for building model airplanes. I need to pick up another small lathe and milling machine. I will pick them up from Little Machine Shop, I looked at Grizzly and compared them and I think LMS has a better machines. I'm getting off track here (no pun intended), Bruk, be looking for an email from me, it will be from sptrainnut.

Thanks everyone for your great responses, I really appreciate it. Have a great rest of the week.

Cheers!!

PS: I apologize for the misspelling of your name Bruk

@harmonyards posted:Blunt tools, or rounded tools, reduce the risk of scratching or gouging delicate surfaces, The variety of different picks opens a lot of options for fiddling a tire into position……..I’m sure you do fine given the amount of tires you swap, but for the occasional tire swapper, the round end picks can prevent a lot heartache…..

Pat

Just don't get aggressive/stabby and the screwdrivers work fine ![]() .

.

But for the average hobbiest blunt/round end tools are probably best.

Thanks Lou1985, that's some good advice.