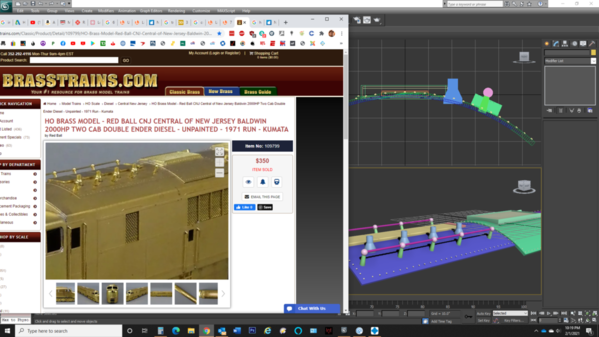

While work has slowed on my CNJ Heavy Mike project due to workspace also being used as classroom space, I figured "what the heck, I probably need ANOTHER half-finished project lying around". So, I give you, the "CNJ DRX-6-4-2000" project. What is it with 3 rails and a general lack of Baldwin diesels? I can find shells to easily make one of these in HO, but other than an obscure kit by the now-defunct Locomotive Workshop, nothing close to these has ever shown up on O scale.

For those unfamiliar, the DRX-6-4-2000 was a double-ended version of the Baldwin DR-6-4-2000, a 2000 HP passenger cab unit with an A1A-A1A wheel configuration built in 1946. Unlike PRR's "passenger sharks" (which are also DR-6-4-2000s), these used Baldwin's older "Baby face" design. CNJ ordered 6 of them, divided into 2 groups with slightly different appearances.

How to go about building one? Well, after some research, it seems the trucks are the same as those used on Alco PA-1s and DL-109s. The DL-109 is supposedly a better fit, as it's close to the DR-6-4-2000's length. The PA-1 is 12' shorter. After a quick search for a donor engine, it seems the best value I could find at the moment was a Lionel 6-18952 PA-1 that I found on eBay. Has TMCC, which saves on a costly upgrade. Sadly, it only has Signalsounds, instead of Railsounds, but it covers the basics. It'll need to be stretched 3 inches, but that shouldn't prove problematic (says the guy who hasn't yet taken off the Alco's shell).

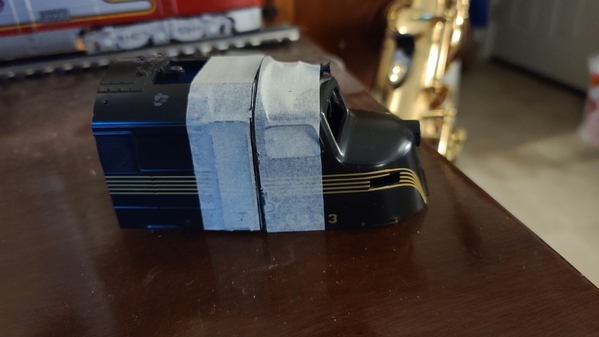

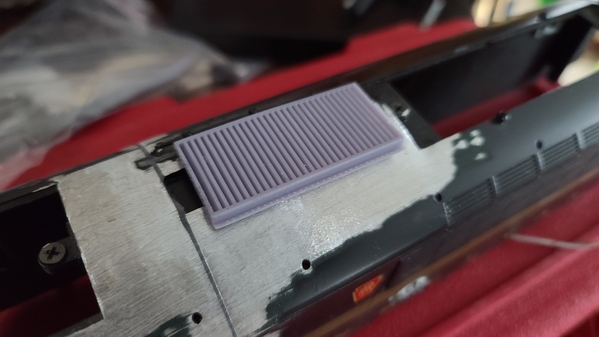

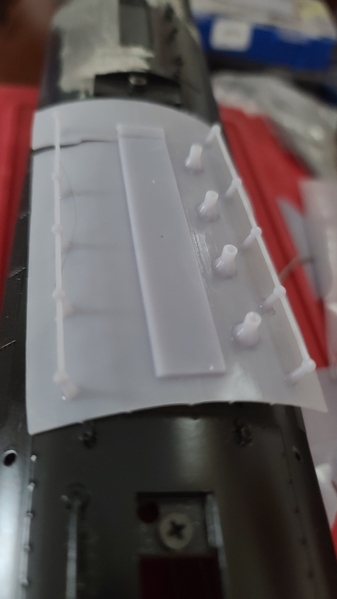

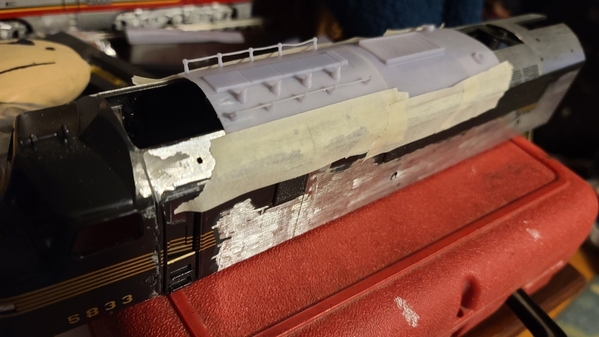

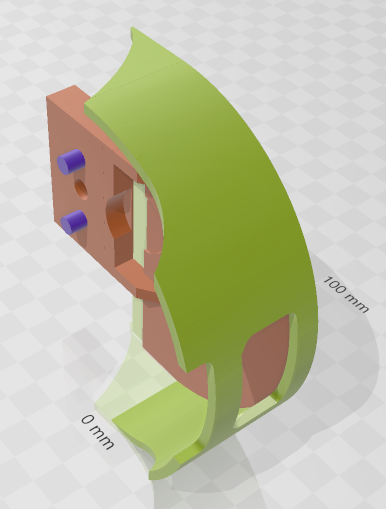

Next comes the trickier part, the body. The ONLY thing readily available with a Baldwin Baby Face profile is the Centipede. Both Lionel and MTH made one, but the cab has an annoying taper starting at the cab door which other Baby Face units like the DR-6-4-2000s and DR-4-4-1500s don't have. I THINK I can offset this using body filler, as it should be less than 1/8th of an inch on the model. I'll have to cut out an inch between the cab windows and the cab door, cut halfway through the first grill (the centipede has 2 grills at either end, and a long set in the center, the DR-6-4-2000 has only 1 at either end along with the long set in the center) and then trim the center section to provide the correct overall length.

Then I have to decide whether to do that all over again for the other end, or make a casting of the first cab and use that for the other. Pics will show up as the project moves along...