I thought I'd share another command conversion I did, this time on the modern remake of the Tie-Jector. The stock one requires you put the track trips along the track to start and stop the process, but that seemed like a bore, so I set out to make this command controlled. One problem is the trips are actually a mechanical process, so a simple electronic control or relay won't do the trick. I settled on a model airplane servo for the motion control, and found one of the smaller ones available, the only thing that would fit in the spot I had. A cable control runs from the servo to the actuating arm for the ejection mechanism. Of course, I removed the existing lever that was used with the track trips. A small bonus was that I was able to sell the track trips for half the price I paid for the entire Tie-Jector! ![]()

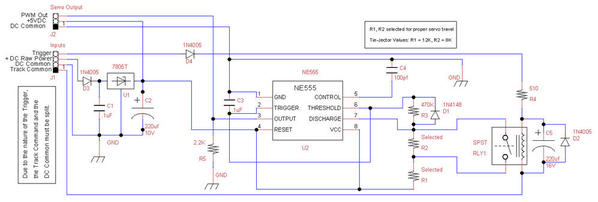

Next, I had to figure out how to drive the servo, it requires a PWM signal for positioning information. Since the ERR MiniCommander didn't offer such a capability, I build a small board that housed the PWM signal generation. That board connects to the servo to provide the positioning. The circuit also required isolation, so a relay is triggered by the smoke output of the ERR board and that actually changes the PWM signal to start/stop the ejection operation.

I added directional headlights and tail lights, a backup light, and a strobe when the ejection is running to complete the picture. It's fun to get the reaction when it starts dropping the ties along the track. ![]()

Here's the completed project.

Here are a few shots of the inside of the unit illustrating how things were mounted and connected.