Looking for ideas for making concrete retaining walls. Please share some images / tips.

Replies sorted oldest to newest

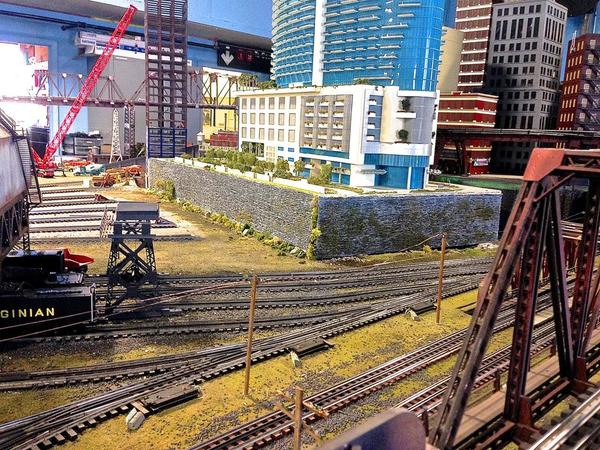

I've used Masonite for the wall itself, with pilaster supports cut from 1/4" pink foam. The foam pieces are glued to the Masonite using yellow wood glue. You need to be careful with foam: hot glue tends to melt it and many solvent-based glues will dissolve it. I used Plastruct railings along the top. The road tunnel is an HO double-track tunnel portal. The wall was painted with Woodland Scenics Concrete Top Coat and then weathered with a black wash. Click on a photo to see a larger version.

Attachments

Bob,

Just amazing work. Could be real.

Very nice work gents!! And economical to boot.

I have over 17 feet of high line that needs a wall in front of it. I was thinking about concrete and thought of foam core, but Bob's use of Masonite certainly works. In fact, it works great. I just bought one piece of Chooch large stone sheet to make a silicone mold and make some plaster walls to see if that works too. Going the Scenic Express route would cost a small fortune which I can't do.

I'm looking at two large walls - one of them is roughly 400 Scale feet in length, ranging from 18 to 24 scale feet in height. It's a pretty sizeable feature - I'm worried about it taking over the scene vs. sitting into it realistically. Photos of others work are most helpful.

I had to take second look it looks so real.

Nice JOB,GOOD LUCK, jOHN

Here are a few of mine from the old layout. All made from MDF in .25", .5" and .75" thicknesses.

Donald

Attachments

My first attempt...

I thought it looked bad without something at the top so i decided to add some detail. May need to add a inset inside this.

I think the color is mostly good - I tried doing mold lines ala Norm. Not too sure about it. Maybe some chalk weathering and foliage will make it look better.

Attachments

Looks like concrete to me, JP. ![]()

Bob,

very well done!

Foam Core

I know Dennis uses Masking paint, but what colors do others use for painting foam?

Attachments

I also use Rus-toleum Camouflage Khaki. Both the Uline Masking Spray and the Rustoleum provide a great aged concrete look. They look about the same.

DennisB posted:Foam Core

Incredible picture.....Dennis' book is a must if you are into urban modelling!

Peter

Bob posted:I've used Masonite for the wall itself, with pilaster supports cut from 1/4" pink foam. The foam pieces are glued to the Masonite using yellow wood glue. You need to be careful with foam: hot glue tends to melt it and many solvent-based glues will dissolve it. I used Plastruct railings along the top. The road tunnel is an HO double-track tunnel portal. The wall was painted with Woodland Scenics Concrete Top Coat and then weathered with a black wash. Click on a photo to see a larger version.

The pics of Bob's layout are great, but to do it justice, get the recent OGR video on his layout....it's fabulous!

Peter

Bob posted:I've used Masonite for the wall itself, with pilaster supports cut from 1/4" pink foam. The foam pieces are glued to the Masonite using yellow wood glue. You need to be careful with foam: hot glue tends to melt it and many solvent-based glues will dissolve it. I used Plastruct railings along the top. The road tunnel is an HO double-track tunnel portal. The wall was painted with Woodland Scenics Concrete Top Coat and then weathered with a black wash. Click on a photo to see a larger version.

Bob, this is amazing. I'd like to use masonite as you have, but I also need to bend the wall to follow an O-72 curve. Will the .25" board bend sufficiently to do that?

Thanks,

OK - second attempt at this is up...

I won't tell you about the removable foam hill I "tried" to make to go where I'm standing in the last photo. That was a disaster.

Attachments

"I'd like to use masonite as you have, but I also need to bend the wall to follow an O-72 curve. Will the .25" board bend sufficiently to do that?"

I use 1/8" masonite for my walls. If your wall is not too high (6 to 8 inches or so) then you should have no trouble bending 1/4" masonite to fit, as long as it is the non-tempered stuff. Non-tempered masonite or hardboard is light tan in color and flexes very easily. Tempered masonite is dark brown in color and is MUCH stiffer and harder to bend.

I'm going the Bartizek way... I drew up the plan and went to Lowe's yesterday to get the Masonite. It's 5.75" inches from the lower level to the top of the upper level railhead. I'm making a 20 foot long wall with buttresses just like Bob has. Here's the good news. The 1/8" tempered Masonite cost $7 and some change and the guy cut all my rip cuts for me. I went home with all the material sized. All I have to do is slice off the pieces with the chop saw. I already have some textured paint for the job. On the left side, the railroad is on an upslope. I may or may not taper the retaining wall to match the slope. It's no big deal to do this. You can't beat the price. I'll have to weather it and put vegetation and vines to break up the monotony.

The retaining wall needs to be quite narrow due to the close clearances between the lower-level track and the wall. Using the 1/8" material means the whole deal including buttresses will be 3/8" and should work... I hope.

The fellow was able to set their panel saw to cut the 1.5" and 1" strips that will form the buttresses. Here's a view of the SketchUp drawing. Using SU I was quickly able to set the buttress spacing, and determine how much stock I needed to purchase. I'm still debating if I want a tunnel to penetrate the wall. The road would have to cross over three railroad tracks.

This will be a nice project for two reasons: it will finally close up that gaping hole under the high line, and will give me something to do while waiting for the weather to be warm enough (without wind) to spray the Distillery boiler house.

Attachments

Trainman2001 posted:I'm going the Bartizek way...

Always a wise choice!

When I started my current layout (which was my first one that wasn't 100% "toy-like"), I scoured the Net for layouts to learn from. I looked at many, but the one I kept returning to was Bob's. It is an amazing mix of craftsmanship, integrity, character and style--with a website to match. Just the right mix of realism and "high-rail" whimsy.

Thanks, Bob!

Although I posted these on my other thread ("Continuing Saga..") it would be fitting to include them here since it was in this thread that I got the inspiration to go ahead with a Masonite retaining wall emulating those on Bob Bartizek's layout. With the help of grandson #1 (14 years old), we put together 20 feet of wall with buttresses all fabricated of 1/8" Masonite. I painted it with beige Rustoleum sand paint and installed it with screws and Titebond glue. It still needs weathering and some landscaping/ground cover.

The bland area on the left side of this pic is where I intend to put a Plastruct Chemical Plant once I finally buy it.

The open area on the right side of this pic will be the land forms that lead to the mountain/tunnel complex that will occupy the right hand back corner of the railroad.

The retaining wall fills in a bid eyesore for me. I'm going to add some tie back retainers to add interest and cover some of the screws. They're going to look like these. I'll make a couple of masters and resin cast the lot since I'll need 20 or so. These will be simple to produce out of flat styrene and some NBWs. Size will be probably 3/4" high X 3/8" wide or maybe larger since my wall is about a scale 22 feet hight so a 3 foot tie back might not stand out when looking at it from 12 feet away.

Attachments

Jacobpaul81 posted:My first attempt...

I thought it looked bad without something at the top so i decided to add some detail. May need to add a inset inside this.

I think the color is mostly good - I tried doing mold lines ala Norm. Not too sure about it. Maybe some chalk weathering and foliage will make it look better.

Jacob, we needed a three-sided wall at our club to cover an area that was in a tight, somewhat inaccessible type of place. We basically did what you did, used pink foam and weathered it and added moss-looking effects/foliage to finish it off.

Attachments

scale retaining walls that actually can and are constructed in full size are the only ones that look OK to me. A concrete retaining wall that possesses a concrete horizontal beam at its top that is wider than the width of the wall below cannot actually be constructed, so that looks odd to me.

I would not build that kind of scale concrete retaining wall. The construction issue with the wider top beam is that if the retaining wall is contiguously constructed with the beam why do you need the beam? However, if the beam is constructed before wall and supported on some sort of post/column framing arrangement then how do you pour the concrete into the wall's form under the beam if the beam is there on top first? Can't be done.

The only exception to the above is when a post/beam frame is constructed first along the width of the wall then infilled with masonry that is later "parged" with a cement coating over wire lathe attached to the masonry. However, this sort of construction has not been done for a while, because over time the coating weathers and breaks off the bricks. This would be a neat look!

I continue to play with and tweak the wall pictured above. As you can see, I've removed the top beam - it just didn't look right. This is from last night - working on the landscaping behind the wall.

I pass under this bridge nearly every day. It's a Frisco Bridge now used by BNSF. Using the concrete as my inspiration. I need to add some black and white touches, but I think the overall effect works.

Attachments

JP,

I like the rough surface from the forms. The RR's didn't always have pretty forms and used scaffolding planks. They are tough and could be reused.

So, that water main is really bothering you. You've redirected your efforts to hide it. ![]()

![]()

AlanRail posted:scale retaining walls that actually can and are constructed in full size are the only ones that look OK to me. A concrete retaining wall that possesses a concrete horizontal beam at its top that is wider than the width of the wall below cannot actually be constructed, so that looks odd to me.

I would not build that kind of scale concrete retaining wall. The construction issue with the wider top beam is that if the retaining wall is contiguously constructed with the beam why do you need the beam? However, if the beam is constructed before wall and supported on some sort of post/column framing arrangement then how do you pour the concrete into the wall's form under the beam if the beam is there on top first? Can't be done.

The only exception to the above is when a post/beam frame is constructed first along the width of the wall then infilled with masonry that is later "parged" with a cement coating over wire lathe attached to the masonry. However, this sort of construction has not been done for a while, because over time the coating weathers and breaks off the bricks. This would be a neat look!

I beg to differ with you on the issue of a "Beam" at the top of a retaining wall. Sometimes a little thought goes into even the most mundane structures. If the designer has a free hand and the people funding the retaining wall are not pinching pennies, the final design can be pleasing.

So a widening at the top of the wall is most likely not a beam, but more of a capital. Some simple concrete bridges over small steams, ravines and even over railroad tracks, have details in them that could have been simply left out. But someone had an eye for aesthetics and decided to put some chamfer strips in the forms to give some lines to the final product. You will see these minute details while driving along any road, especially older bridges.

Some retaining walls have pilasters. On a higher retaining wall pilasters not only add strength, but they make the wall more pleasing to the eye by breaking up the monotony of the large expanse of concrete.

Cap Cod ...

>>>>I recycled the cork roadbed that I removed from under the tracks. Cut it to size, painted it grey and combined it with Plastruct components to resemble a modular slab style wall. <<<<<

What a great idea for construction a modular slab style wall.

Sherward ... a 67 year old retried Bridge Engineer.

I also beg to differ with AlanRail. My concrete retaining wall with a cap is based upon a presently existing retaining wall in Kansas City used along a BNSF right of way going over a street just like in my photo. This is typical of concrete designs dating back before WWII. In fact they're all over KC.

Moonman posted:JP,

I like the rough surface from the forms. The RR's didn't always have pretty forms and used scaffolding planks. They are tough and could be reused.

So, that water main is really bothering you. You've redirected your efforts to hide it.

Hey Carl,

Thanks - I borrowed my technique from a very well respected source. I've now made several attempts at replicating molded concrete walls...

All in various stages of completion. I've been playing with whether I need foam behind the long wall on the north end of the layout (1st shot).

Right now the biggest problem is the sprinkler line handle (pic 3). If it was shorter, I could get get by with 8" clearance, but with its length, gotta have 12. I'm probably going to build a removable warehouse flat here to encapsulate - gonna have to be big - like 30" long, 15" deep, and 19" high - I'll probably build up the hillside some so it's not quite so tall.

Attachments

Above are a few examples of old concrete retaining walls with a cap or lip. I just shot these today in Kansas City. Dan has it right. The capital, as he puts it, is done for aesthetic reasons. One is more likely to find such ornamentation on older walls. I venture to say these walls may have been constructed as early as 1920.

Now, I have no argument with however one wishes to model their retaining walls. There are modern day retaining walls without any cap. My issue is with those who present opinions as facts. Simply because one believes something to be true, doesn't make it so.

Dennis, the pics are great. And boy, the amount of weathering is daunting. I refuse to put a handrail on 20 linear feet of concrete wall, even though it would be prototypically correct. I did put hair pin railings on my two deck truss bridges.

DennisB posted:Foam Core

Is it real or is it Memorex. Great modeling. Took me a few minutes to decide it was a model.

Dan.......this is a great picture.....Dennis' work leaves me in awe!

Peter

DennisB posted:Foam Core

This photo amazes me every time I see it. It is just an outstanding piece of art. ![]()

![]()

George