I agree. These forums introduce each other as people with interesting lives (including our love for trains and miniature things).

Let me answer the first note first. No, this person is not older. He's a 50 year-old that watched me build models in my garage at our PA townhouse. He and a bunch of other little guys living on our cul-de-sac used to spend lots of time watching my craft and it stuck for some, this fellow specifically. For his 50th he got a ride in the "Yankee Lady" one of the several extant flying B-17s. He went out and bought the Revell kit, but quickly realized that he'd never get around to build it and decided to get a "Myles Original" He was willing to pay me a commission, but my wife and I thought that wasn't necessary. Since he's in Philly and we're in L'ville, I suggested he return his kit and I'd re-buy it here. I also bought PE and aftermarket engines for it. It will be a good build. I'm blogging it daily, like my railroad, on another couple of forums including this one if you're interested.

http://cs.finescale.com/fsm/mo...1907123.aspx#1907123

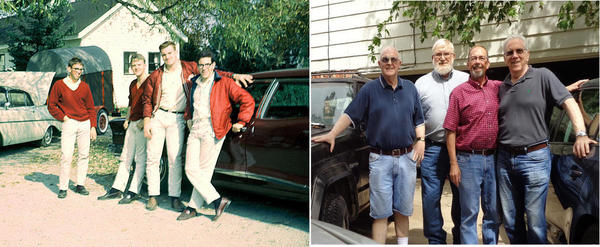

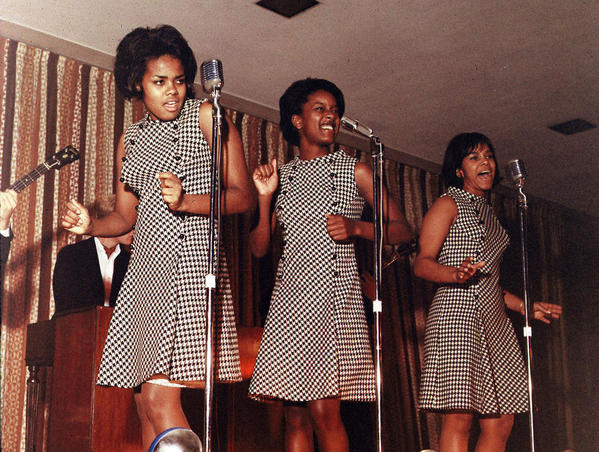

As to the second. All of us "Sounds" are 71 and our birthdays are within months of one another. If the health of Roger Edwards (vocals and keyboards) holds up, we're planning on doing some 50th extravaganza maybe on Michigan States Campus next year. There's a lot of "ifs" in this scenario including getting some additional funding to get all the members, equipment, venue, etc in place. I'm looking at options. It really depends on Rog beating cancer.

If any of you know about Gary Kohs and Fine Art Models, he's officially stopping the manufacture of his world-leading museum-level models. He's been at it for 25 years and producing masterpieces by artisans all over the world. You may know about George Kohs and his staggeringly detailed brass O'scale equipment. George is Gary's brother. Fine Art Models now has a museum dedicated this his craft in at the Mariner Theater and Galleries in Marine City, Michigan. He bought this old theater and completely restored it. The models there are both FAM manufactured and from Gary's personal collection. I'm putting it on my bucket list. I visited Gary's business twice when he was in Birmingham, MI. I first saw his work at a showcase at Detroit's Metro Airport. It was when he first got started. I had to find this guy and on one of my Michigan business trips called him and went for a visit. Of course they didn't manufacture there, but they did inspect, repair and re-ship his products. His office was a modeler's Mecca, but what lay in the next room blew me away. It was a large room filled with amazing models that Gary had been collecting. It wasn't for the public, but it was awesome in the most literal meaning of the word. It did inspire awe in me. There were trains, ships, live steam, engineering models... everything.

I then visited again some years later and saw their 1:192 rendition of the Battleship Missouri. I was in love. It's price was $8,500 and I put my name on the waiting list. That was until my wife found out about it. My name promptly came off the list. We couldn't afford $8.5k for a 50" museum model. We didn't even have a place to display it. Needless to say, if I took my $30k+ that I've invested in O'gauge trains over the years, I could have owned several FAM models. But that train, as they say, has left the station. I'm not a rich man and can only handle one vice at a time.

Anyway, Gary is closing down because the artisans are dying off or retiring and there are no apprenticeship programs anywhere in the world to replace them. That is very sad! It speaks volumes about what is valued today, and, more importantly, the impact technology is having on the creation of engineering prototypes. In WWII you had to build scale ship models (1:48 masterpieces from Gibbs & Cox) for the process to continue. Today, you can do this digitally, and you can 3D print what you need if you need physical objects. There are still some models made, but the numbers are way down. I entertained going into the architectural model business years ago when I was a shop teacher. Those too have been greatly supplanted by 3D drafting programs and rendering engines that do the job much faster, cheaper with less labor. These skills have disappeared because they're no longer needed widely in industry. They won't come back and it's our responsibility as modelers to keep it alive if that's at all possible.

If you haven't ever looked at what Fine Arts Models has accomplished, check it out here.

http://www.fineartmodels.com/Welcome.html

Even though I can't afford them, I can admire them. I can't afford a Rembrandt, but I can sure admire them.