I agree on the cardboard over screen. It looks great, just like the tunnel approaches were dug out of the mountain side!

Thanks Mark. Did you have a nice Birthday?

I'm a God in reverse. God makes the mountains and the railroads punch holes in them. I make the railroads and build the mountains on top of them.

Birthday? ![]() I keep missing these national holidays.

I keep missing these national holidays.![]() Good thing a new calendar gets bought soon, this one was left blank the last few days.

Good thing a new calendar gets bought soon, this one was left blank the last few days.![]()

Trainman2001 posted:Thanks Mark. Did you have a nice Birthday?

I'm a God in reverse. God makes the mountains and the railroads punch holes in them. I make the railroads and build the mountains on top of them.

Adriatic posted:Birthday?

I keep missing these national holidays.

Good thing a new calendar gets bought soon, this one was left blank the last few days.

Myles,

Yes I did; easy day at work, went out to eat with my wife, daughters, and sons-in-law, they stopped at the house for cake, and my mother-in-law came in for cake. So that was all good.

Yes the tunnel making is in reverse of real life.

Adriatic,

Yes, Nov 3rd is my birthday. I turned 60 this year, but no one made a big deal about it. Just another birthday. Every so many years my birthday is Election Day, but I would call that an anti-holiday. Thank you for commenting however!

Sorry dude, but 60 is a big deal. All those decade birthdays are a big deal. It means you can't die of a heart attack in your 50s. Five more years and you can have Medicare and cheap movie seats. In Philly, you can get an Amtrak ticket to NYC from Trenton for $7.00. So some birthdays are definitely worth celebrating. I'm 71 so I am no longer going to die in my 60s. It's kind of macabre, but I like looking at it like that.

On the arm topic... according to son in law, medical people aren't even sure why you need the long head bicep tendon. They think it may help stabilize the shoulder joint since it threads over top and fastens behind it, but you can function perfectly well with just the short head doing the work and they, apparently, never break. He said I was lucky that it actually fully detached. If it doesn't, it continues to hurt forever. They go in and surgically cut it. It retracts back into the arm and the pain goes away. If you're going to wreck your shoulder, this is probably the best of the worst things that can happen. It's one of those rare instances that "rupturing something" is actually a good outcome.

Re: Montjuic... I was going to cheat and not put rock detail on the wing walls facing away from the viewer, but then I considered what the train-mounted GoPro camera would see entering and leaving the tunnels. So here's how I'm going to try and handle it since painting the rocks in situ would be difficult. I'm going to pre-mold/pre-shape the rock walls, and then color them off the mountain. After plastering them in place, I'll just have to touch up the joint areas. The forward portal wouldn't be too bad, but the rear-facing wall is very hard to reach while lying on the layout.

Trainman2001 posted:I'm 71 so I am no longer going to die in my 60s. It's kind of macabre, but I like looking at it like that.

I'll join your decade in March and I don't think it's macabre at all. Some years ago I made a list of how long my parents, grandparents and in-laws lived. I then figured out the day and year I'd surpass them in longevity. So far I've passed my father in 2004 (he died young) and my paternal grandfather in 2015. Next up is my maternal grandmother in 2023. Ever since our granddaughter was born, just turned 10 on the 1st, I've had this "thing" about my mortality and what I'll probably miss in her life. That didn't happen when the older grandsons were born, but I wasn't retired then and didn't have a lot of time on my hands to think about things. My maternal grandfather lived to be 103, so I doubt I'll get too close to that. ![]()

Myles and Dave,

LOL!!!

Interesting ways to look at aging! I have realized I have outlived one grandfather by 4 years, and by 65 would pass my other grandfather and a grandmother, but don't think much of it. My main thought was to see our daughters marry and get on their own. Marked that off two months ago. I would like to retire and be able to share my trains with grandchildren, but if I don't see that, oh well.

Interesting on the shoulder. As ong as you can use it and it doesn't hurt, that's great!!

Reading back a few pages, Mark and I were conversing about how my generation has outlived our parents and grandparents generation. It's probably the first time in human history where my grandchildren have all of their grandparents on all sides living and functional. And almost all because of modern medicine, not any longevity genes. It's why I'm not taking the joy for granted of spending time will all of the grandkids and imparting whatever wisdom, encouragement or skills that I can. I wish I had grandfathers who could have done that for me.

I agree! Both my grandfathers passed away before I was born and I was the first grandchild. Yes, they both probably would have lived longer if today's medical advances had been available. Also, it is quite possible if I hadn't had that one little statin pill each night for the last 20 years, that I would not be here typing this message right now.

I agree also, Mark. None of the men in my family have made it past 75 - some earlier.

I've got 5 years to go to break the record. ![]()

I take my statins - although my cardiologist tells me that a new study shows they work better if they are interrupted occasionally, so I stay off them on the weekend. It seems to be working, so far . . .

Back to the subject - it's all going along well, Myles. I'm with you every step. ![]()

Being alive is definitely a plus. And... being alive and well enough to build a model railroad is like the best of the best.

Well... the mountain has its first coat of plaster finished. I took more care in ensuring good plaster mass in the paper towels, as a result, the work that did Friday cured rock-hard and can support my hands pressing on it. Today I did the remaining areas. After laying it all down, I went back with additional plaster to cover any obviously thin areas and to refine the seams between towel layers. In this way I've precluded the need to add another 1/4" of Gypsolite as a second coat. This just bought me about 3 days of production time.

There's a little hint of the underlying cardboard, but it's really not noticeable (IMHO) and I'm pretty sure I'll be able to paint and landscape on what you see here. I also cleaned the plaster off the roadbed on the future track in the foreground.

I went over the whole deal with some more Gypsolite on the previous work to fill in any obvious holes and lumps. I also chipped away excess that was fouling the track next to the masking tape. I then made some templates of the wing walls. As I noted in my last post, the idea is to pre-make the wing walls even as far as coloring and then apply them to the mountain. Here are the three templates.

I then put masking tape on the Bragdon Rock Mold to delineate an area to add the plaster. In this way I "Near-Net-Shaped" the part reducing the plaster cutting that would be needed.

This really worked better than I thought it would and created a pretty well shaped piece. There was just a little bit to be trimmed with a hack saw blade. Here was the piece fitted to the rearward facing wing wall at the back portal. That hole at the bottom and the fit on the left edge will be handled with scultamold (which I will pre-stain something more rock like to reduce painting.)

I poured another mold before quitting today and will pour the last one tomorrow. I'll be ready to start painting everything on Wednesday.

Attachments

There are a couple of milestones in the building of a layout when magic happens. You are in the middle of one of them. ![]()

![]()

You've got that right. When done work today I'm looking at it and saying to myself, "I'm building a freaking mountain!" it was a large space to cover and very daunting. So... you've just got to start. Once you start it becomes less threatening. The goal is to have everything running again by Thanksgiving. That goal is quite reachable now. I've got little kids waiting on it.

The wing wall castings look great! I think the mountain will look great, and you will have everything cleaned up in time.

My family has been back pedaling from 80-102+ since the late 1700s - 1800s to 50 -80 for those born in the last century. Each generation dying sooner since 1912, the year my last living grandfather was born. Half his children died before he did. Its the industrial city life IMO. I'll be lucky to to reach actual retirement age it seems. Things started breaking and popping in my forties. Younger cousins dying before me. Those my age dropping like flies in the cold. How old? Well, I dont recall the Kennedy's but turned on and watched the Apollo in B&W and for the first moon step I was all alone. I remember Curt Russel doing spy toy commercials and my first crush was a pretty nun on a motor scooter. Then soon after I cried with my Grandfather at the thought of Lionel going bankrupt ![]() .

.

The mountain? I'm too busy watching it grow. When I'm "quiet" I'm often at full attention ![]() A fan of overkill , my only thought has been I hope its still thick enough for a good bump or off balance lean if you skip that layer of gypsolite.

A fan of overkill , my only thought has been I hope its still thick enough for a good bump or off balance lean if you skip that layer of gypsolite.

Well... the things do start happening in your forties, first you lose close vision, then if you're heading that way, the blood pressure and cholesterol start showing up as problems. Then you start having joint problems. That being said, the BP and LDLs are controllable. My numbers are better now than they were then even with meds in both cases. And regarding the joints and stuff, that sort of levels out to a tolerable level of annoyance. So you kind of get into an "aging groove" which barring catastrophe, you can keep going for a while. My model work is superior or equal to what I did 40 years ago.

Back to the mountain. I did find some soft areas when I put some extra weight on my hand. Instead of slathering on more Gypsolite and wasting more drying days, I just laid on a layer of Hydrocal which I brushed into smoothness. This did the trick and the mountain is secure. I poured more wing walls. In one case, a couple of pieces broke off and I was able to repair them. In another, I de-molded too soon and it broke into many more pieces. So I abandoned using the masking tape on the mold. Instead, I just took a fat marker and traced the wing wall template. When I did the pour I just steered it around the lines.

When I de-molded, the marker lines amazingly transferred to the molded rock. This enabled me to scribe the lines with a utility knife and snap off the excess giving me a well-shaped rock wall. Again I had a couple of repairs to make which I did with a combination of Aleen's and CA. It only has to stay together long enough to plaster it in.

After trimming this is what it looked like. The notch at the point is to clear the protrusion on the tunnel portals.

Here's the other remaining wing wall after gluing on the errant piece.

And here's what they look like when laid in their ultimate resting place.

Tomorrow I'll pre-paint these walls and install them into place using a full load of Scultamold behind them.

Attachments

Besides having a miserable cold and being up most of the night due to the elections I had a very productive day. I'm doing another multi-tasking project with mountain building, and while plaster hardens, building another nice model aircraft; a Trumpeter 1:32 ABM Avenger. This ones for me and I'm going to add a lot of bells, whistles and crazy details.

Today, I got the wing walls painted and installed.

As planned, I painted them off the layout to reduce the contortions I would have to endure in doing this on the layout. As it is, I will have to do touch up painting, landscaping and ballasting in those positions.

Again, the rock painting followed W-S's guidelines. I used their tinting colors first with a yellow ocher band surrounded by slate gray.

When this dried I sprayed it with W-S Scenic Cement to fix the colors and then used an India Ink/Alcohol wash followed by a earth toned wash and lastly hand brushing acrylic grays to highlight the strata. Here's the finish product.

To imbed these castings into the mountain, I mixed up some Sculptamold with some added India Ink to tint it gray to make touch up easier.

It took two full batches to get everything in place. Where parts of the casting broke off, I was able to fill the gap with Sculptamold. After getting everything set in, I went back with a wet (old) paintbrush and smoothed out all the interfaces. Here are the three wing walls in place.

Where the Sculptamold over laps the castings I scribed some strata and when touch up painted, you won't notice the transition.

I definitely think that preparing, cutting and painting the castings off the layout was the way to go. Notice that I tilted the strata which is quite often the case in the Appalachians. In fact, one of the identifying aspects that you are, indeed, in the Appalachians is the tilted strata that is so prevalent.

By tomorrow (I hope), the STM will be set and I will be able to paint the new mountain terrain and get on with the removing the masking tape (which has done a yeoman's job) and finishing up ballasting and tie cleaning. By next week, we should have trains running through the tunnel.

Attachments

I'm very impressed with the color shades you make!

Congratulations !

Trainman2001,

Absolutely love the way the rocks turned out, to my eye you nailed it! I've been trying to model Silver Creek in Southern Indiana which has predominately shale banks. So far I've been less than happy with the results. I'm going to give your methods a try, so thank you very much for the post!

bd

Adriatic posted:It looks great already. Like a winter scene.

Yeah. Reminds me of the time I modeled a ski area with snowmaking machines:

https://ogrforum.ogaugerr.com/t...46#37611053597842846

![]()

Thanks guys. I'm not really into winter scenes. Today I didn't do any mountain work since the thick slabs of Sculptamold are not dry yet. I find large sections of that stuff seem to dry in two stages. first the plaster of paris hardens in minutes, but the fibrous portion can take days. Since I want to paint this ground color, I must wait until the plaster is dry or the paint will seal in the moisture. So... until it fully dries I'll be working on the aircraft kit. Here's the engine being built. It's a Trumpeter 1/32 ABM Avenger. Thats a Wright R-2600 radial. The Trumpeter model is well engineered.

Oh... and one more thing. I bought 3 more BCRs to put into some more of my older QSI/PS1 engines. That will make 8 conversions with 4 more to go. They're expensive, but they eliminate so many operational annoyances.

Attachments

It's Saturday so no train work, but I was downstairs checking on the drying Sculptamold (it is dry BTW), and noticed a natural notch that would be a terrific beginning for a spring fed "natural" stream going down the slope and ending in a pond that will be built in the open area between new and existing track.

Here's the path. I'll have to add some Sculptamold to build up the terrain at the bottom so the "water" would flow to the pond and not over the (or under) the track.

I'd put some strategic rock casting at the starting point with the water coming out of them. It could add some more interest to this expanse of plaster. The pond would be on the lower left out of the picture and right up front which would facilitate doing some nice vignette work around it.

Attachments

All the Sculptamold (STM) on the portals is dry, but instead of starting the painting today, I contoured the stream bed adding lots of STM and various rock shapes that I had lying around. Now... I don't really know if any geological formation actually would appear like this, but in order to get the flow to bend to the right so it would end in the pond that will be created, I had to make the stream bed.

Notice: My pre-coloring the STM didn't really make it that dark. It would take a lot more pre-color to darken the STM so it wouldn't need much paint. Therefore; I didn't add India Ink to this new STM project.

So here was the before:

And here was the after. I added a strata rock face up top from which the water will emanate, a series of rock was of the right side (looking at the mountain), and rock ledge over which there could be a small water fall, and then a rock-lined channel getting the water down the mountain. I added a couple of rocks in the middle of the stream for interest. It's hard to visual this with it all being white, but when all the coloration is added it could work.

It took a lot of plaster to reshape the mountain and blend the rocks believably into the existing contours. The rocks don't show up without painting, but they will.

I mixed the plaster with a bit less water than I used when setting in the portal wing walls, and I'm hoping that it will cure faster since I need to get cracking on the painting and landscaping.

Attachments

Today was a big day! The plaster was dry enough to do the painting and landscaping. Lots of crawling around on the layout and bending at funny angles. I left the very front area where the mine's going without any terrain since I'm not sure how it will sit and don't want to forego any options in its installation. It's not a show stopper since all the track and trains can run while I'm building that. Meanwhile a train did run today.

All the rocks around the stream bed are now colored, but the stream bed itself is unpainted. I'm going to do a little research on how best to do this.

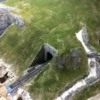

Here's look directly down showing both portal areas and the stream run. I put a small rock ledge in the flow so I could have a little waterfall. There's also some rocks in midstream to add interest. This pic was taken before ballasting was completed on portal tracks. Masking the tunnels was the right thing to do, even though it was a bit challenging to separate it from the thick plaster at the edges, but I persevered. The unfinished areas in the lower left is where the next terrain will tie into the mountain. That's coming up next.

I started to glue down the new track beginning with the critical switch. I first had to trim about a 1/16" off the switch's track edge so it wouldn't impinge with the track on the swinging door. I'm using Liquid Nails to hold the track down to the Flexibed and then weighing it all down till it cures. I need to buy more Liquid Nails before continuing. I'll get it tomorrow.

So here is the mountain which I'm calling Montjuic after the big hill in Barcelona Spain. It translates as Jewish Mountain so it's kind of appropriate. The Super Chief ran the tunnel with it's "new" engines leading the way without any mishap. This picture was shot with the EOS and a 71/210mm lens and using Zerenstacker photo stacking depth-of-field software. It was shot at medium telephoto and took 15 images to get all of it in focus.

This picture too was shot the same way with less telephoto. It took 8 exposures.

I was thinking of the pond to lie in that triangular gap between the two tracks in the foreground, but there's a bigger space lying beyond, so now I'm thinking to let the stream drop a bit more and put a stone-arch bridge over it with the pond in the larger space. Thoughts?

While I want to get onto the remaining terrain work, the floor is an absolute mess and I think I'll clean that all up before any more work. The family's coming for Thanksgiving and I don't want them seeing that floor.

Here's that Avenger engine after finishing it up yesterday, in case you're wondering. I can almost hear the whine of its started motor. I'm an equal opportunity model builder as you can see. If it's small, I like to build it.

Attachments

The scene is really coming together nicely! I like the stream falling down and through a stone culvert idea!

Thanks Mark! It will give me something to work on in case I run out of things to do.

With errands to be done today, only had time to glue down the rest of the new spur.

All went well, but I noticed a gauge misalignment with the new switch and the track on the swing gate. It appears that the left hand rail on the switch is not in gauge since the center and right rails line up perfectly. Ross rails are spiked and glued so moving that rail might be difficult. I may just grind that part that's sticking out a bit so it aligns better and doesn't snag any equipment. The two sets of tracks also didn't align vertically, but I fixed that by slacking off the riser holding the subroadbed on the swing gate, raising it up about a 1/32" and then re-tightening. It's one of the advantages of using L-girder. Things are easy to adjust.

Just before the left front tunnel portal is switch "L". It's one of the original switches that ties the back passing siding into the inner main line loop. It stopped working, and the problem was tracked to the old model Z-stuff switch machine's terrible lead attachment method. The set screws press the wire to a contact spot on a small circuit board and it's flexible. Contact is easily lost. The new models have pigtails soldered directly onto said board, and I think I'm going to take that machine apart and solder the pigtails myself. I did get it working, but it needs a double tap on the push button controller. I have a ton of those early versions. BTW: that's a pretty closeup shot of the roofing granules ballast, and they look pretty good. Their size is just about perfect for O'gauge. Just don't get Magna-Traction near them. They're slightly magnetic.

Attachments

That's a long way out, Myles. ![]()

I agree about the granules. Have you thought of staining a few of them and mixing them in?

I have used dark alcohol/India Ink wash to tone it down in some locations.

Today, I was going to ballast the new track, but got side-tracked on a futile mission. Before I get into that, I took a movie of my MTH Veranda pulling a train on the new spur. The misaligned switch track didn't cause any trouble in this run. I'm going to try and re-gauge that one piece of track.

Switch L, one of the older Z-Stuff 1000 switch machines (which I briefly discussed in last post) was bugging me and I thought (wrongly) that I could disassemble it, remove the set screws pressing the wires again the printed circuit pads and replace them with soldered pigtails like in all the new versions. I was getting poor connectivity and erratic operation. That switch is now partially hidden by the tunnel's wing walls and I didn't want gimpy operation in that remote location. So I took the switch machine off and disassembled it at the bench. I was so concerned about not losing any of the small screws that I neglected to pay attention to the mechanical arrangement.

These switch machines work with a small permanent magnet motor and spur gear, applying torque to a bevel gear which connects to the switch throw. The complication comes in with a cam that operates a microswitch that shuts off the drive and illuminates the red or green LED position indicator. Soldering the new wires to the circuit board was the least of my problems.

I then attempted to put it all back into the housing. The board was hard to get seated down properly because the gauge of the yellow wire was just to fat to handle the bend. I replaced that with a black 24 gauge solid conductor wire. Then the red lead to the motor broke off at the motor. I couldn't easily strip that tiny lead so I removed it entirely and replaced it with a new lead. The the brown wire broke off at the circuit board. As I was manhandling it back in place the blue wire broke off. You starting to see a pattern developing here?

When I got it all in place, the motor was bound up. I had the cam on the wrong side and it was pressing against the pinion gear. Took it apart again and re-aligned all that, and it was still stiff so I took it apart again and rearranged the wire runs which were pushing the motor out of position. Then the pinion gear came off the motor shaft. When I started to CA it back on, smarter brains prevailed and I stopped since I didn't want it on the gears or motor bearings.

When I finally got it all together and back onto the layout, it moved a couple of times and then the motor was spinning free since the pinion let go again.

Bottom line! I need to buy a new switch machine. I'm going to order two since I need a space since these things are really difficult to repair. Meanwhile, I'm pulling one of least used ones off the railroad yard and putting it back next to the tunnel since it's one mainline. I replace the yard switch motor when the new ones arrive.

Normally, when I attempt to fix something, I actually make it better. This was one of those rare times when things got worse.

Hopefully, I'll get the ballast down on Monday and clean up the mess all over that end of the basement (including the floor) since it just plain awful and don't want guests to see it.

I've taken thousands of pictures with my iPhone and never realized until tonight that even after holding your finger on the screen to set the aperture and focus, you could continue to change the exposure by sliding the light symbol up and down. Doh! So I took two pictures that show stuff in a different way.

The first is the interior (rarely seen) of the Victorian Station.

The second is the substation with the lighting more subdued looking more like it does to the eye.

Attachments

Nice run on the video, and the mountain looks great! The lighting and exposure makes the interior look great, and if I didn't know better, I would think that was 1:1 substation!! You will be in good shape for Thanksgiving!

1

Thanks Mark! Speaking of which; everyone have a happy and safe Thanksgiving. Careful on the highways and careful deep frying those turkeys. It's the one time of the year that all four of our grandkids are together.

Well... a rare Saturday session since I really needed to get that switch fixed and wanted to put the finishing touches on this phase of mountain construction. The next time I'm in the basement it will be to clean up the floor.

First thing I did was ballast all the new track. Typical process:

- Pour ballast between the rails and spread it forward with an old paint brush

- Pour ballast on the edges over the roadbed and brush and shape so roadbed is hidden and tops of the ties are clean

- Spray area with "wet water" which water/alcohol and a few drops of dish detergent

- Soak area with W-S Scenic Cement out of a small nozzle.

- Let dry overnight and go back and secure any loose areas.

Where the mine's going to go I added some dark stuff to the mix since that area will be covered with spilled coal.

Lastly I did the new switch. Notice, I do not ballast in the area where the points are.

Next I realized that I needed to add the missing fascia so I quickly did that. It really finishes it off. It will be painted the forrest green (of course), but that will happen another day. When I built all the existing fascia I used Masonite splice plates held together with screws and nuts. It was overkill. In this case I just put some Titebond glue on the joint plates and temporarily clamped till set. There's little or no stress on the fascia so I use very small Phillips head #2 screws. Space on the right will be fully landscaped in the next phase.

I added another piece that finishes off the yard end. Look closely and you can see that horrendous floor.

So here's all the work completed so far with all the extraneous crap removed. The three yard tracks in the foreground are where the large engine house is going. I'm working on the final planes for that. Still not sure if I'll have it laser cut by Andre or use some other method. It's going to be quite big, have a ton of windows and I want it to be brick. That 2 X 4 you see sticking up in the background was that extra support I installed to stabilize the working board I was relying on to reach the difficult parts of the mountain. Hard to believe that beast is just cardboard.

While all this was drying, I got back to work trying to make a working Z-1000 switch machine for the switch that's just in front of the left front portal. Since I was having so much trouble getting it back together I thought I take a fully functional machine from a little-used yard switch and install it back there since that's a critical location. Seemed like a prudent way to go and then buy a new machine to replace the one in the yard. Remember what Clausewitz said, "Strategy is over the minute the first shot it fired." This strategy was over when I tried to pull the three-wire pigtail out of the hole in the layout and ripped all three off the circuit board in that yard switch machine. It seems that all three wires were plastered solidly into the hole in the platform since the plastering in the yard was all done after track was installed. I almost had to chisel the remains of the wires out of the hole. Hydrocal is very strong and hard when fully set.

So now I had two defunct switch machines. I knew that the one in my hand was a good one so all I had to do was re-solder the wires back onto the board. Hmmm.... seems like I was at this same place yesterday. This time I was going to be smart by photographing the guts before removing anything.

It was a brilliant idea to take this picture. Too bad I was too stupid to refer back to it. In looking at it now I realized that I, a) had that white motor wire reinstalled from the bottom up instead of how it's here exiting the board out of the top, and b) I think I have the microswitch upside down so the lever is on the bottom instead of top as it is here.

That's why after screwing around with it for a half hour, it still worked poorly when on the railroad. And this was a good one.

As it did the last time, at least four existing wires broke in simply handling all the parts. The white motor wire broke off the board. And the wires on the microswitch also broke. Their little, short wires and are very hard to re-strip. I believe these wires are breaking since they are cheap, 2-strand Chinese wires that are too brittle. The wires I'm using to replace them have at least a dozen fine strands and are very flexible. In the motor wire's case I made a new one, but I soldered it into the board from the bottom. This caused trouble getting the wire out from under the board. I should have realized something was wrong—and checked this stupid picture—when I couldn't get the green LED back in its socket because the green wire was running directly beneath the holes. I moved it out of the way, but still had it coming from the wrong way. The other clue was not having enough room for the LED current limiting resistor since with the microswitch upside down, that resistor was now right next to the motor and there wasn't much room for it. I think I'll put that machine and rearrange stuff correctly. I'm slowly getting good at this, but it's a very painful learning experience.

More troubles happened when the connecting spring from the machine to the throw bar disappeared into the quantum rift. But luckily, Ross had sent me a bag of these puppies years ago when I had lost one. For the now missing yard switch, I installed a Caboose Industries ground throw so at least the switch can be maintained in a specific direction.

Oh... and I lost a green LED from the machine when I forgot to remove them and popped the circuit board up. When that happened the LEDs went out forcibly. I found the red one, but the green is not in this dimension any longer.

I don't give up easily and am going to try and secure that pinion gear on the other machine and rebuild it correctly and see if it will work. New one cost $26 plus shipping. While it's not a bad idea to have a spare or two around since they're so critical, I'd like to need them because they wore out, not that I've broken them.

All in all, the mountain looks great, but the rest of the day was an exercise in frustration.

Attachments

Thanks for posting, Myles. An interesting read. ![]()

I feel your pain. ![]()

Overall work looks great! I too feel your pain over the switch machines!

On placement of the "pond", why not "ponds"; two.? You've got the grade. A full sized one to the rear and a small shallow flood basin closer; the trestle bridge or culvert crossing splitting them. It would even allow a rocky and/or marshy version of either too; wade in with pants rolled or dive.

I think that's a splendid idea. I checked and there's a clear shot under the subroadbed where I can narrow that section and build the stone arch bridge. That's another advantage of L-girder in that you can do things like this after the railroad is constructed.

We're having family over for the holidays, so the first part of the day was spent scrubbing the upstairs bath and cleaning spaces that aren't used very much. Then I did get downstairs and did a couple of big things.

I made a 'tool' to both scrap the plaster splatters all over the floor and vacuum up the powder at the same time.

This gizmo let me scrap and clean a lot of floor very quickly without crawling around on my hands and knees and got the piles of plaster removed and sucked into my very strong shot vac. I then actually washed the floor. It probably needs it again since it kind of splotchy, but it's sooooo much better and it's at least presentable.

I then quickly painted the new fascia and the large one that borders the mountain. This really dressed it up.

I then got back to that errant switch machine realizing that the wiring could be improved so all the wires from the board coming out the top. Even the factory-fresh one didn't have all the wires this way and it puts a lot of stress on the bends and leads to breakage. I had to cannibalize from the other machine for a new motor since one of the metal contact pieces broke off the motor due to too much force when installing because the wire was coming from the wrong direction. I also had to get the other microswitch since this one started to separate into two parts. I also used the pinion gear from the "good" one for the motor from the one that had the slipping pinion.

When I finally got all the new wires installed, everything routed from the right place, the microswitch oriented properly and all buttoned up and on the railroad, it worked perfectly. No hesitation! The only thing I had to do was reverse the red and green LEDs so they represented the correct track direction.

So now I had one completely rebuilt and other that was total trash. I then called Steve at Ross Custom Switches and ordered two new Z-1000 switch machines. One will be re-installed in the yard to replace that manual throw and the other will go into inventory in case another one fails.

I then wanted to show all this great stuff to my wife. I first found that something is fundamentally wrong in the wiring. Whenever I turn on the right throttle or left, both go on. I will have to trouble shoot this tomorrow since it makes running two trains impossible. The other thing I found was the Veranda kept derailing when it went over my front grade crossing. After a cursory look I found that the Bristol Board was completely delaminating from the foam underneath and was catching the turbine's pilot and derailing it. I glued it back down and added weight to keep it there until dried.

Using Bristol Board over green foam was the worst decision I made on the entire build. It has been a maintenance headache almost from the start. It would have been better if I used plaster directly over the foam. Or if I used the 3M high strength spray adhesive...

When not working on the layout, I was doing this on SketchUp 2017. It's the same engine house I've been noodling for a couple of years, but I'm getting closer to the point where I have to build it. This was a SketchUp/Podium rendering and then superimposed on the layout using GIMP photo editing software.

Here's a fun shot of the interior. It's not finished yet. I still have to develop a roof truss system and doors and round window. Even though I drew inspection pits, they will be difficult to execute since I've got hydrocal poured between the tracks to give me a "level" railroad yard look which will require "demolition" to remove. Actually in order to implant this large building into the layout all of that will need to be cut out. Of course inspective pits with 3 rail track are always sub-optimal. Both the GP-38 and that neat overhead crane were downloaded directly from the SketchUp Warehouse. Amazing! I designed it will massive concrete pillars separated by brick walls. I'm thinking of making a silicone mold and casting the pillars of our Hydrocal.

That was yesterday. Today, I solved all the operating problems. There was a train shorting out the system which was making both throttles alive when you opened on. I don't know how or why, but it got solved. I had to reverse the switch machine position since Z-Stuff machines on the outside of a curve get hit by my big engines. They must be on the inside. This was discovered when I attempted to take the H-8 on its first run through the tunnel and it came to an abrupt halt when it HIT that switch. Of course this was not as simple as it seems since it meant breaking out now-hard ballast, drilling new holes for the wiring, and finding that the pigtails were now to far from the junction block under the platform and having to move that to a position and closer to switch. The red/green lights needed to be switched on the machine and the button since the throw is not reversed.

I re-ballasted the switch and then another area feeding into the far right portal that I had left undone. I then cleaned off the work table where all the plaster and cardboard mess was created. It's the first time I saw the whole table in months. That's the old engine house mockup I made.

Lastly, the H-8 also didn't clear the rock cut wall. Even though I moved it back a inch, after putting all the rock work on it, there are some high spots that were kissed by the pilot. I will do some sculpting to remove those spots. Meanwhile, like real life, that monster will be confined to mainline track leaving the tight spots to smaller engines. That white spot didn't exist before the collision.

So... everything is running in time for my son and family to arrive tomorrow including two very savvy granddaughters.

Attachments

I just love this thread.

Some day I need to drive down and see your creation!

The scraper-sweeper is a great idea! The mountain looks great! I like the drawings for the enginehouse. It will be another focal point of the layout! You have earned a great family get together this Thanksgiving! I wish all of you a great Thanksgiving!!

Today was the last day to get everything in ship shape before guests so I decided to run all the equipment through and around the tunnel, and Boy! am I glad I did. First there was the H-8 kissing the front left tunnel portal. While the portals were wide enough, I should have mounted them a little to the right to give more clearance on the outside of the curve.

That was bad, but not critical. Then I tried running the big Baldwin Centipedes and that was critical! The front unit cleared the portal and the front edge of the rear unit crashed right into it. Stopped it dead!

This could not stand! It meant that I had to perform in situ surgery on that portal. I can't remove the portals. They are literally part of the mountain now. So I did the next best thing. Got the Dremel with a carbide router blade, taped the portal so I had a cutting line and went at it. This is the rig I use.

And here's the result. Crude, but I'm in no position to mess around here. I painted the exposed green foam and trimmed that poor curve with a sanding drum before painting.

Here was the now-not-so-pretty portal. From the layout front, you can't tell and now everything passes through the tunnel easily. I really couldn't test this before since all the track was covered in masking tape and trains couldn't run.

Then it came to test the new outside mountain track. The H-8 kissed it too, a little too heavily I might add. So I took an heavy duty Xacto handle and blade and chopped off the obvious high spots till it cleared. Whew! I thought that was it. Then I tried the Centipedes. More collisions and more critical. So I chopped more high spots off, but this time I had to hit the knife with a soft-faced hammer. Finally got it to clear. Then I brought out the Coal Turbine. I thought that the middle unit had similar geometry as the Centipedes, but I was wrong. More kissing...serious kissing, and more chiseling.

So here's how much plaster I needed to remove before everything cleared.

And here's what it looks like after repairing it. Since it's all "rock" it just looks like rock again. Amazing. After this picture, I re-did all the ballast that got disturbed and then ran all the trains around and around for about a half hour.

Oh... and one more thing. I decided that the way the trains were running indicated that my track was dirty. Boy! Was it filthy! The trains ran much better and the horns didn't blow unexpectedly. The kids just arrived so I'm signing off. Happy Thanksgiving!