Happy Monday… what again! I've been trying to figure out why the days and weeks are going by so fast and have some up with a possible theory (despite that I'm just getting old). When I was a working man, I was up a 6:00 a.m. and on my way to work at 7:00. Now I'm up somewhere around 9:00 and don't actually sit down for breakfast until almost 10. That means I'm unconscious for about 3 more hours per day than before. That's 15 hours a week. No wonder the days felt longer….They were longer. This is a long post so bear with me...

We're getting near the end folks! I got the Widows Walk installed, installed all the those crazy downspouts, put in the plumbing stack, added weathering on the top knot, added some weirs so "water" would end up in the water buckets, and started making a master for the parapet capping system.

Mounting the downspouts should have been a no-brainer, or at least a half-brainer. Instead it had the makings to be a real pain in the butt. Several things contributed to this. First there was breaking four 0.032" carbide drills. Drilling the hole wasn't breaking them; pulling them out of the hole did. They're $1.50 each, so I blew $6.00 making 8 holes. Then there was the breaking of the solder joint when I was putting too much pressure on the brass pins when inserting them in the holes. This was complicated by having the aging treatment affecting solder ability. I ended up filing off the old solder. I also changed from using the TIX, which seems to solder well ONCE, but doesn't seem to have any strength on re-soldering. Instead, I used standard 60/40 rosin core. I was afraid of un-soldering the whole deal so I clamped a hemostat to prevent the long downspout from coming loose.

To close up any gaps around the water boxes, I added some shaped styrene to act as a weir. I added some styrene up top also for the same reason so the "water" would leave by the scuppers and not run over the edge around the parapet wall.

The plumbing stack was just a piece of 1/8" brass given some aging.

On Saturday, I went with a friend to an open mic jam session at Mom's Music in Louisville. We didn't play. I was just checking on the competition. I am totally out of shape having not played much at all lately and have no callouses. I did by a neat Wah Wah pedal on sale for $70. I am now officially entering the 1970s musically. Anyway… this person is the retired CEO of a large, commercial roofing company. He said my gravel is okay, and he said there probably would be a roof access hatch in the top knot. So I added one today and then glued the top knot in place.

I then added all the Widows Walk pieces. I was able to neatly join them and had plenty of extra to use if I broke anything. I did… The pins worked well and I added some thick CA to join separate sections and to tie down any loose ends.

Finally, I started crafting the master for the terra cotta parapet capping. I'm using Super Sculpey to make the master. We just bought a new toaster oven after our 30 year old Black and Decker's toast switch stopped latching. But the oven controls still work fine, so it's now in the shop where I can more conveniently bake my Sculpey stuff. I went on line and found some specs on these. There was some vintage ones on eBay and they measure 26" long. I found a piece of 1/4" MDF scrap from this building and molded the clay on top so it would be the correct bottom shape. The master doesn't have to be strong… just strong enough to hold its shape when I do any finishing on it and when surround by liquid silicone.

It's not final shape. I've learned that you shouldn't waste your time trying to get Sculpey perfect before firing (275° for 15 minutes for each 1/4" of thickness). Instead, you make a basic shape, fire it, and then it's stable enough to work more details and get it perfected. Once I get it the way I want it, I will create a silicone mold and cast a bunch of replicas for the total cap. A 1 foot scale wall thickness is not out of line with real world practice. I may make two of them since it takes about 1/2 hour for each resin cast to cure. That will be many hours of curing time. I may start building the Thunderchief while I'm casting all these multiple parts.

I put some weathering powders on the top know roof so it wasn't so pristine.

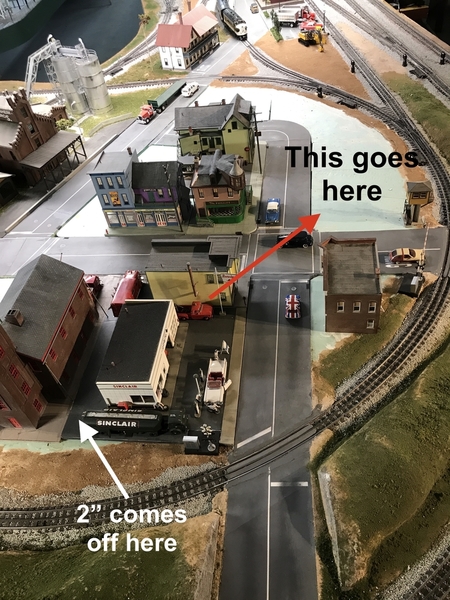

With the parapets finished the building WILL BE DONE. What's left is creating the base plate and siting it on the layout. I'm still debating (in my mind) how to fit it at the corner I want and what to do next door to its left. This building is 2" wider than Saulena's and that 2" will need to come out of the Sinclair Station.

Here's where Saulena's and Sinclair Station will go. Sinclair is 17" deep, and the space near the tracks on the front is 15". I can get the 2" off the back of Sinclair's base plate and it will simply flip from one side of the street to the other.

Then Bronx and the Appliance store will move into the vacated spot. Bronx is a foot long so fits perfectly in length. It's 2" wider and that will come out of the parking lot. The appliance store will be rotated 90 degrees to the right some the display windows face the parking lot. Should be enough for about 8 to 10 parking spots.

Lastly, I still need to find stuff for the vacant lot on the other side of town. Ideas are welcome.

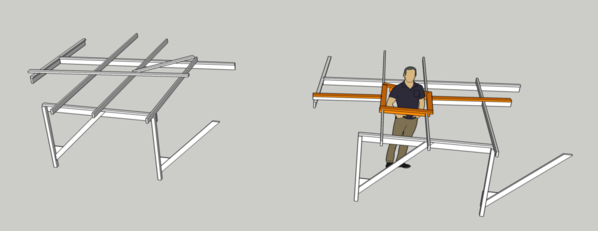

On another topic: I bought Phillips replacement LED tubes for a florescent fixture in out master closet. These are not plastic tubes like occasionally goes on sale in Costco, but are glass enclosures and very substantial. They're not cheap ($16/tube) but their light is terrific. You can get them in about four color temps. I chose 3500k, which is a neutral white. I was buying complete fixtures to replace all the florescent fixtures in the basement since I had tried the Costco tubes and one caught fire. I now know that you have to be very specific about what types of ballast is in the existing fixture to get the most compatible LED. The Phillips lights are correct. Now I'm re-thinking actually replacing the rest of the fixtures, since it's not so easy restringing lights over an existing layout. Replacing the tubes is much less hassle since I don't have to disturb the power connections. It's within a couple of bucks of buying new fixtures. Then I had the problem of not only disposing of the florescent tubes, but also the now obsolete fixtures. So from now on, I'll be replacing the tubes one fixture at a time. All the lights over the town are now LED. The rest of the layout is Florescent. You can see the level of light intensity is much higher with the LEDs.