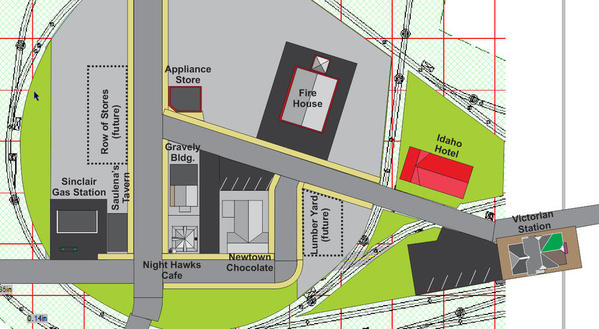

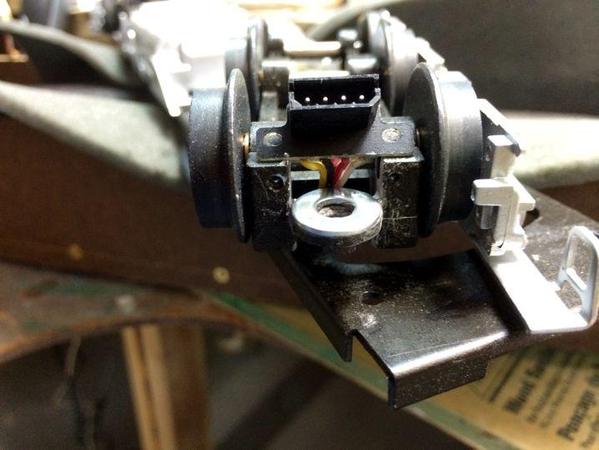

Thanks to Miller Engineering, the new florescent driver came yesterday and I was able to install it in the Sinclair station and get it back on the layout. I also finished detailing the base plate for the candy store and the future site of the Night Hawks Cafe. Both of these are now on the layout.

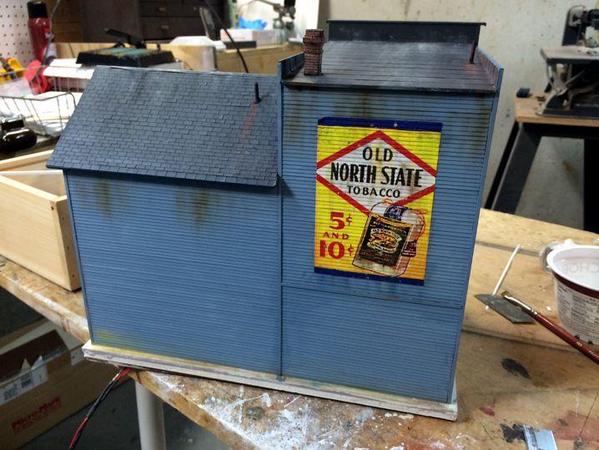

The candy store's base was a hodge podge of foam core pieces that needed to be covered with something else before painting. I also needed to put edging around the perimeter to better simulate a curb.

Because I was covering the base with an already-finished model stuck to it, I didn't want to spray the base with spray adhesive to stick on the next layer, so I used Aileen's Tacky Glue. If I was to do this again I would not use a water-based glue since it caused the paper covering to buckle as the paper absorbed moisture.

I carefully cut the paper to work around the building. Of course the building's walls aren't exactly straight nor square so I had to custom fit the paper in many places.

I used 0.010" styrene to trim the sides held in place by CA. The large gaps you see were subsequently filled with CA and after painting are not noticeable.

I mixed a batch of paint to match the concrete color of Model Tech paint, but it came out a little to "wet cement" looking. I'll live with it, but I need to prefect the mix.

Before painting the sidewalk, I measured and scribed the expansion joints on four scale-feet spacing, plus an 8 scale-inch curb line. After painting the first coat, I went back over every line with a thin-line Sharpie adding some simulated cracks and then put another lighter coat on top to tone down the joint lines a bit.

It was a little touchy getting the edging to join under the curb cut, but after slicing it and removing a tiny bit of stock, it stopped bulging out at that spot.

After painting the sidewalk I masked and painted the asphalt portion of the loading drive, and then used my earth tan acrylic house paint to paint the back yard and under the loading dock. Before this dried I sprinkled it with light gray gravel for the back and light buff for under the dock.

I painted and aged the fuel oil tank, glued some other details around the property and added a couple of W-S figures, and it was ready to go onto the layout.

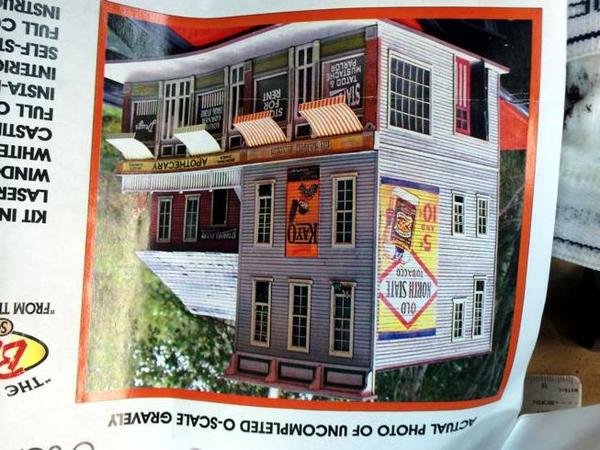

The white bare lot next to the candy shop is the future site of the Night Hawks cafe. Behind this on the right could be the Bar Mills Gravely Building if it fits, if not, I'll check the base board size when I start that kit. The side street sidewalk is about 4 scale feet, the main street's sidewalk is a scale 7 feet.

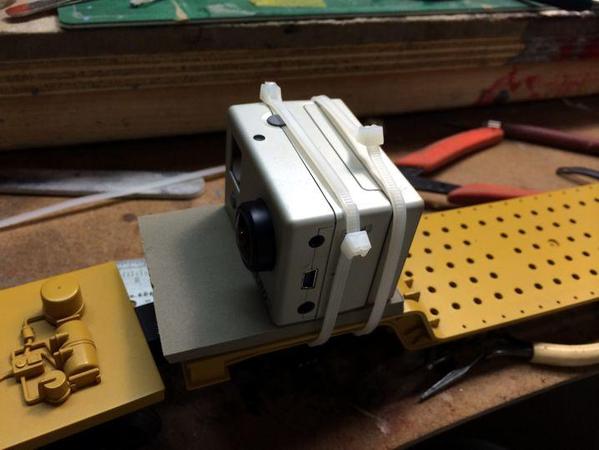

I also installed the Sinclair station and dropped its wiring through the layout.

Both new buildings are waiting for the electric company to hook up their service. I've been told that they going to do that on Monday. BTW: I tested the new driver board before putting it on the layout and it worked fine.

Both new buildings are waiting for the electric company to hook up their service. I've been told that they going to do that on Monday. BTW: I tested the new driver board before putting it on the layout and it worked fine.

So here's looking down the layout to the buildings that are now in place. It's like watching a real-life community being built with the good lots being taken first.

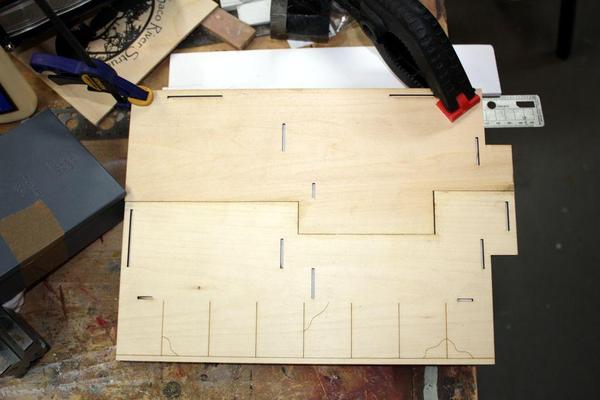

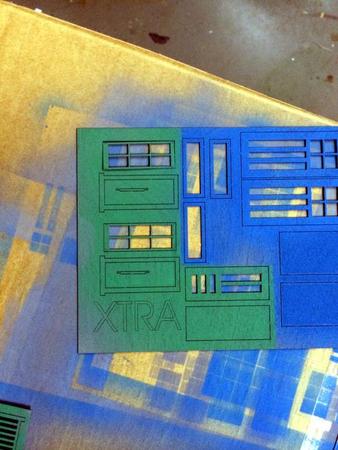

If the laser cut parts don't arrive early this week, I'm going to start the kits that I have.