I like your progress and you are building a fine layout, but I am curious as to why you chose to ballast before scenery was complete? I have always been in the camp that ballast comes last. It seems to me that once you put scenery down you will have to go back and touch up the ballast. At least that has been my experience. I'm not trying to be negative, just wondering what your thought process was. Either way it looks like you have a very nice layout going there! Thanks for sharing.

To ballast before or after scenic treatment? Hmmmm.

I thought about this a lot and then Gayl Rotsching pushed me over the edge by saying that ballasting before is much easier. I tend to agree.

My thinking was based on concern for getting the switches carefully ballasted so nothing would be binding and having ground cover all laid down first would just get in the way. And when I'm ballasting tracks that are a bit out of reach I'm standing on a step-stool and supporting my weight with one of my arms with my hand pressing firmly on OSB, not ground cover.

As to aesthetics, in looking at the Southern and CSX tracks here in Louisville, the ballast encroaches on ground cover and vice versa, so whichever goes on first wouldn't matter much. New ballast lies on top of the grass and weeds, older ballast has weeds and grass on top. But it will be a lot easier laying in imprecise ground cover than it is shaping the ballast bed.

I ran out of scenery cement again today. Instead of running to the hobby shop again (I'll do that tomorrow) I took two jars of Aleen's Tacky glue and mixed it 1:1 with water. It filled one of the empty Woodlands Scenics bottles so I bought some time. It seems a bit more viscous than Woodlands Scenics glue, but it worked. I'll see how it dries tomorrow.

It still astounds me how much material a pike of this size consumes. Whether it's screws, ballast, scenery glue, whatever... it takes at least 3X more than I estimate. But it looks so good when the trains go on long journeys and get really small as they move to the other end of the room...

I have enjoyed watching your progress since you started posting. It is coming along great. I look forward to your future posts. Jon

I intend to keep writing as long as folks, like yourself, are reading. This post is going to go on for years.

There is a terrific RC aircraft forum called RCScalebuilders.com. Some of the finest RC aircraft modelers in the world document their builds in great detail—which is where I got encouraged to do the same thing. One build I'm following is almost 10 years long and the model's not done yet. It's a 1/6th scale AH-1 Skyraider that even has wings that fold and lock under servo control. Good things take a long time.

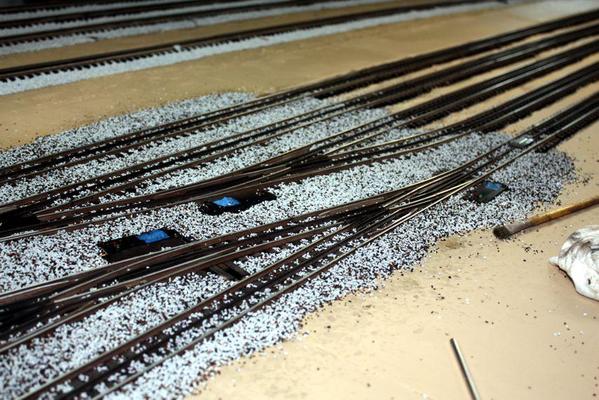

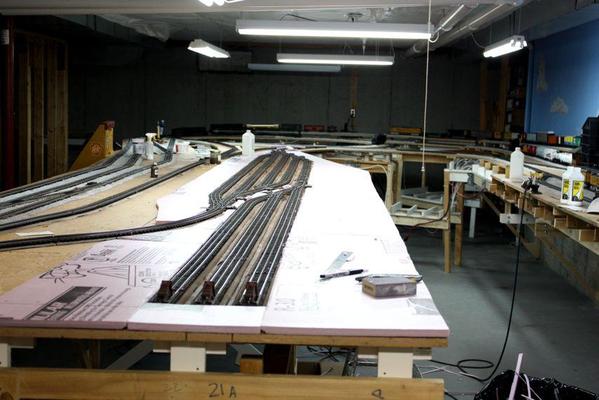

Ballasting is about 3/4 complete. I finished the back side of the railroad and the left side. All that's left is one mainline track coming off the reverse loop and all of the foreground yard tracks. I finished spraying rust brown on almost all the remaining track and will finish it all in the next work session. I'll ballast the mainline tracks as before, but can't do the yard tracks until I do one thing first.

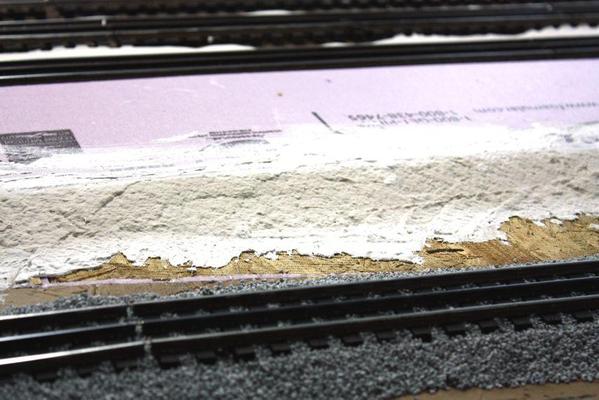

I have to raise the ground level all around the yard tracks 1/2" so the ground level is just below the tops of the ties. Yard tracks are buried; they're not elevated and groomed like mainline tracks. Often you can't even find the ballast. It's often a mixture of dirt, cinders, and maybe some ballast. I'm hoping that I can find some 1/2" pink foam board. I don't want to use plywood, and I have some bead board scraps that could be used in a pinch, but they're slightly thicker. Once this filler is fitted, then I'll be able to do the ballast/ground cover.

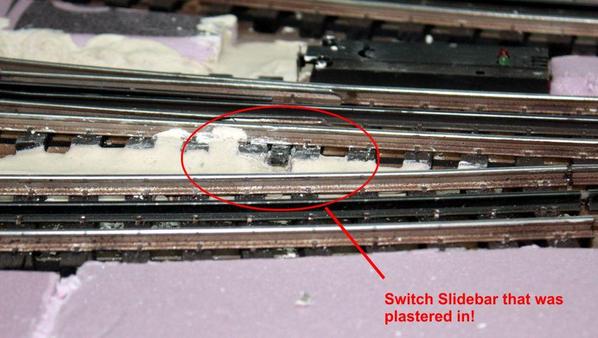

Here's an overhead shot of a typical switch showing "NO BALLAST" in the moving parts, and the car that it takes to get the ballast shaped right and not fouling anything up. Doing the switches is finicky and takes time. I exercise their motors to make sure that nothing is blocking them.

I one instance I accidentally got some stones down the slot where the manual controls is. It immediately jammed up the works. I had to remove the switch machine, turn it upside down and knock the stones out. Once cleared, everything worked okay.

I may have mentioned this before, but I've stopped using the ballast template that I made and just carefully distribute the stones from a plastic sour cream container. The template was springy and sprayed stones all over the place that had to be corralled back into place.

The actual steps I use are:

1. Do about 3 feet at a time. This seems the right amount so the wetting agent doesn't start drying before you get the glue down.

2. Pour a moderate amount of ballast down both sides of the power rail for the center ballasting.

3. Using an 1-1/2" cheap paint brush, sweep the stones towards one end until the ties are clear of stones and all the spaces between the ties are full and flush with the tie tops. It takes a couple of passes to get this right.

4. Pour a modest amount of stones towards the ties on the outside of track. Let the ballast fall naturally down the slope of the roadbed. Use enough so you don't see any roadbed showing through. This was very challenging especially in those areas that had very little subroadbed sticking out of the side. In a couple of places I used pieces of styrofoam bead board as extensions do the ballast had someplace to fall.

5. Use the brush and lightly sweep the stones of the tie ends. Go back and clean the center track area again.

6. With the brush, lightly push all the loose stones that are spread out from the track towards the ballast bed until no stray stones are seen. Make any final adjustments to the pile necessary to make a good-looking slope.

7. Repeat this for the other side of the track.

8. Liberally spray the ballast area with 50/50 alcohol/water mix until it's wet.

9. Dribble/pour/drip the glue onto the wet stones starting with the center track area. Go down one side of the power rail then back up the other. Try to keep glue off the rail tops, but it really doesn't matter since you're going to clean all the track running surfaces after gluing.

10. Dribble/pour/drip glue on the outside rail area working in and out of the tie ends and all the way to the bottom of the pile. It needs to be saturated. Stones that don't get wet by glue don't get stuck and will end up being loose.

11. With a rag wrapped around a finger, clean off the the rail running surface to prevent any power transmission problems. If it dries, use some alcohol to remove it.

I didn't ballast the temporary track where the bridges are going to go. It will hard enough extricating those pieces without having them glued in place with ballast.

I think engines look much better on ballasted track, don't you?

The ballast looks awfully white in this picture. It's really light gray. I think I'm going to do some weathering on it, especially some grime running down the center. I may also go back and airbrush some rust on the ballast under the rails. My gun doesn't have pressure control and if it's too strong it can blow the ballast out... ugh!

Here's the yard tracks that are now painted.

Through careful juggling and a flew low speed collisions, I was able to get all engines and rolling stock away from the layout front so I could spray the yard tracks with impunity. I also let many of them stay under power since they were suffering from low battery problems.

It's going to be a lot fun getting them all back where they came from.

Attachments

The painting is finished (other than doing some weathering on ballasted areas). I even tried to go back over with some rust brown on rails with ballast under them. It worked....sort of. I quickly found areas that weren't glued well when the ballast blew all over the place. It didn't happen often, but when it did it made a mess.

I also bought a nice 1/2" piece of Owens Corning pink foam board at THD. It will be easy to cut and build up the yard areas. I had them chunk it into three pieces so I could get it into the back seat of my car. The pieces don't have to be continuous so dividing it up won't matter.

I'll be able to insert my structures into the foam to raise them at ground level. An example of this is the control tower (Model Tech Inc.) that I built on a piece of foam core.

What should I use to coat the foam before putting on ground cover?

I bought more Woodlands Scenics Scenery Cement (2 bottles), and a container of black ballast to mix with the other to start concocting the ground cover for the yard.

Since I've been running through the Woodlands Scenics Scenery Cement like it was water — water that cost over 8 bucks a bottle that is — I decided to ask my local hobby shop owner if there was a better deal if I ordered in bulk. Too bad that Costco doesn't sell Woodland Scenics products. He came in in the mid 6s which worked for me and I bought 10 bottles. Even after the ballasting is done, I will still need lots of this stuff for general ground cover gluing, and there's a lot of ground to cover.

When all is said and done, ballasting alone will run well over $200. Most people never mention how much it actually costs to build a big railroad. It's probably like owning a yacht. "If you have to ask how much it costs, you probably can't afford it." But, I am interested in understanding what kind of investment is necessary to bring a big pike to completion. It costs a LOT! The big costs: lumber, track, roadbed, wiring, are understandable, but the scenery stuff nickels and dimes you to death and will probably match the cost of the major chunks. Hopefully, it's spread over many months so it's easier to budget.

I so totally agree with your comment on costs.

And I see you went with cookie cutter benchwork. I didn't understand your comment about losing ballast to the floor until I saw the pictures and realized that.

I really like your painting the rails and have decided to do that on my new layout now.

I noticed the rust color on the ballast under the rails in your picture and may do one coat, then ballast, then a light second coat to get that effect.

I really appreciate the time you spend documenting how it is going, this is very helpful.

Glad to help!

As I noted in the last post, when you airbrush after ballasting, you'll quickly find which is glued and which ain't. I had my youngest grandson go around and test areas to see if there were any loose stones and then fix them. Both boys left for a month of sleepover camp so I'm on my own until sometime in July.

On Saturday, young grandson and I started laying down the foam to build up the areas around the yard tracks. This went sort of okay. I was using low-temp Woodland Scenics (hereon being noted as WS since I'm tired of typing out the full name) foam hot glue. It works except on the big sheets it was already setting before I got the foam in position and it didn't stick. We resorted to putting the glue on one end, getting it fit and then lifting the remainder and stuffing glue under it and moving towards the other end. Then I'd go back and lift the panels in any loose spots and shoot some glue underneath. It's all adhered now.

Before setting in the sheets I beveled the edges so they'd nestle down into the bevel on the Flexibed rubber roadbed.

The foam is a bit higher than the ties, so it's going to be a bit strange as I start laying down ground cover.

Then we found out that cutting thin strips to lay down between the 3.5" spaced yard tracks was next to impossible. Grandson suggested filling the space with melted plastic like the hot glue gun. I explained that it would be difficult to do, but I could use plaster. So I located a distributor in Louisville who sells Hydrocal or Hydrostone in large quantities (Jefferson Lumber). I was going to get plaster soon anyway so it just pushed up the schedule a bit. I bought a mixing head at Harbor Freight Tools and an inexpensive kitchen scale so I can accurately measure the water/plastic proportions. I'm buying the plaster tomorrow. The water to plaster ratio is pretty specific based on USG's spec sheet. For Hydrostone, it's 32 parts water to 100 parts plaster by weight, ergo the scale. You're also required to soak the plaster in the water for a few minutes before actually mixing. This lets the water remove the air that naturally surrounds the plaster particles when shipped.

So the plaster won't leak out thought the wire holes and various other joints I filled them with hot glue melt. Hydrostone is self-leveling and should be good stuff to fill the area between the tracks so I don't have to bury them with ground cover. Plasters is much cheaper than ground cover. I'll probably tint the plaster for whatever I'm making so it's less obvious and doesn't show "white" when it's chipped.

Here's the foam laid down to build up the yard topography.

I'm going to taper the transitions between higher ground and table level so you won't set that 1/2" ledge. I'm thinking about elevating the ground a bit between the mainline tracks and the yard to give a visual break, but I'm concerned about obscuring the switch position indicating lights. I don't have the control panel marked yet regarding which light position on the switch controller corresponds to track position on the actual switch so I'm still doing it visually.

Today, I'll finish the normal ballasting of the last mainline track shown by the track branching off from the mainline track in the above picture. I'm also going to buy the plaster. That should be fun!

I used scraps of foam and the glue gun to close up any remaining gaps in subroadbed panels.

Attachments

On down slopes the ballast will take on a black oily color from the residue of the brake shoes while on the up slope tracks the ballast will remain its natural color. This is very evident on pictures of the Horseshoe Curve.

Jan

Jan, that's true, but my slopes are bi-directional since all the trains have access to both reversing loops. I'm going to do some light airbrushing down the center with some weathered black on all of the tracks... eventually so the break dust will be coming.

Today I started the plaster operation. First I off-loaded the 50 pound bag of USG Hydrostone into sealable paint buckets. Working out of the paper sack seemed a major mess waiting to happen. I bought the plaster at Jefferson Lumber for $22. That's seems like a fair price and is much less expensive than buying those one quart containers of WS scenery plaster. I also bought a bottle of the WS Raw Umber Tinting liquid to kill some of the high-whiteness of the plaster.

The digital scale worked great, but I didn't use the mixing head. It's just too big to stir the quantities of plaster I'm creating. Here's all the stuff.

For several years now I've been saving all the poly containers from cottage cheese and sour cream just for this moment. Here's the routine: I take a cottage cheese container, put it on the scale and tare the weight. I then add 64 grams of water and a couple grams of tinting.

In a separate smaller container, I put in 200 grams of Hydrostone (after re-taring for the smaller container). I then pour the plaster into the container with the pre-measured water and mix until thoroughly homogenized and has a consistency of pancake batter.

Using these containers lets me make manageable lots sizes where I can carefully control the pour.

After I use the container, I set it aside and take another one, add the water and so on. I'm using about 8 containers. Once I get to number 8, the plaster in number 1 is hardened sufficiently where I can flex the container and break out all the plaster which doesn't stick to the polyethylene. I then re-use that one and keep going. I'm able to measure, mix and pour pretty quickly doing it this way and clean up is easy.

Here's some pictures of the plaster filling the spaces between the yard tracks.

While it looks pretty lumpy, the yard ballast mix is going to bury everything right to the tops of the ties. If I go higher than that, I'll have to make allowances for flangeways and I don't want to do that.

I could have probably tinted it much darker, but I don't have much tinting material. I may paint it earth color before ballasting.

Just before I quit and was going up for dinner, I looked over it from the front side and saw to my horror that I plastered over one of the throw rods of a switch. The plaster was pretty hard already. I immediately got a hobby knife and dug it out until it moved easily. That would have been a disaster if I couldn't free up that switch. Removing track from this layout now is next to impossible.

This shows the corrected error. I will be more careful on the other end!

I'm going to go back and re-shoot the rail brown before ballasting since some plaster got onto the track's sides and looks awful.

Attachments

Another problem solved...

I was ballasting the last remaining mainline track and got a little over-zealous ballasting around a switch and again got stones into the manual mechanism. So I removed the switch machine and turned it upside down to successfully shake out the stones. When I went to re-install the machine, the ballast had invaded the space where it sat and kept it from seating properly. So I got the shop vac and removed all the loose stones. When I went to re-install the machine again, I noticed that the little spring wire that connects the machine to the moving point arm was missing.

Uh oh! I vacuumed it up! I now had to find it in a proverbial haystack of yuck. What to do? The spring wire would be invisible in the vacuum's tank. It's spring steel, therefore it's magnetic.

I've been collecting the old Soni-care brush heads because they have very strong rare-earth magnets on them. I took one of them, swished it around through the muck and Voila! Out of the muck was the spring wire. Problem solved!

Interestingly, the roofing gravel that was vacuumed up was also sticking to the magnet. Something in it is mildly magnetic. This may be something to consider if folks that run post-war Lionel trains with magna-traction want to use this inexpensive material to ballast their pikes. It may be attracted to the axles and therefore the gear train.

Great photos &commentary. I feel your pain (LOL). My layout is 53' long by approx. 40' wide. I did a lot of ballasting. 4 5gallon pails of ballast & unknown gallons of glue.

Good afternoon Trainman

Sure is coming along very well. I use Fusion Fiber for the area between and along side tracks, very forgiving and easy to work with also reusable.

Clem

I took a look at that product... I'm not sure I like it, but it may be worth a try.

Today I officially finished all the mainline ballasting. Meanwhile the sculptamold is still drying. Unlike the Hydrostone which sets up chemically, this product seems to need to dry as well as set-up plaster-like. I took a look at my ballast inventory, and much to my disappointment, I'm afraid I'm going to have to buy another bucket. I won't be consuming the whole thing and have no idea what I'm going to do with the surplus. Perhaps another O'gauger will see an ad on Craig's list for 20 pounds of white roofing granules and think it's a good deal.

I'm going to mix the yard ballast with black, and earth tones to make it look more yard-like. In fact, it should probably be more mud and cinder-looking and show no ballast at all. It's a big surface area and I don't want to have to buy bottle after bottle of WS colored ballasts for this last part of the job.

Here's the last area of mainline trackage with ballast. This one piece of track is the most difficult to get to the layout and I had to sit on the layout to get to it. I use a couple pieces of heavy cardboard to spread my load and keep me from sitting directly on the tracks. The layout—all L-girder—doesn't even creak when I get on top. It's a very strong way to build.

Those white wedges you see are pieces of beaded Styrofoam that I used to extend areas where there wasn't enough subroadbed sticking out to hold the ballast. The remainder of those open areas will have to be covered up with something on which to landscape going forward.

Here's the bit of Sculptamold that still damp after almost 48 hours of drying time. I'm not particularly happy about that, but I had something else to do in finishing the last bit of mainline. When discussing the ballast consumption with my wife, she asked if I put it on too heavy. I said I didn't think so. To back up my opinion, there's that interesting GE add with the talking car from the old TV show. Knight Rider, discussing how smart the new GE locos and then it paces the engine. It's a N-S engine GE44EVO and then there's a nice overhead shot that shows how wide the ballast pile really is, and I didn't overdo it, not by a long shot.

Sculptamold has a nice organic texture that will look good when painted and covered with vegetation.

Attachments

I bought some more tan paint from THD and painted all the foam and Sculptamold so it would provide a more "realistic" base for the all the yard ballast. I then finished up the feeder track into the yard with the regular ballast and alcohol/water mix, but then converted the tail end to the mixed yard ballast and the weathered wetting agent.

I'm using a mixture of alcohol/water and a couple droppers of India ink for the yard wetting agent. It dulls it down a bit.

Here's the painted areas. It already looks better without the pink foam showing.

The yard ballast mix is the white roofing granules, W-S coarse cinders and W-S coarse brown ballast mixed in relatively equal proportions. I'm just filling up the track areas to start. The foam is slightly higher than the track ties so the very outside ballasting is a little fuller than the between-tracks ballasting. Again, it's a hassle to keep the stones out of the switches. I finally resorted to putting some masking tape over the manual control opening.

It's still a bit bright so I may go back and do some more air brushing and weathering of the tracks.

This first picture shows the ballast piled up before spreading. Notice how much brighter it is than the glued area to the left. That area has been treated to the India ink treatment.

And here's the track after spreading, wetting and applying glue.

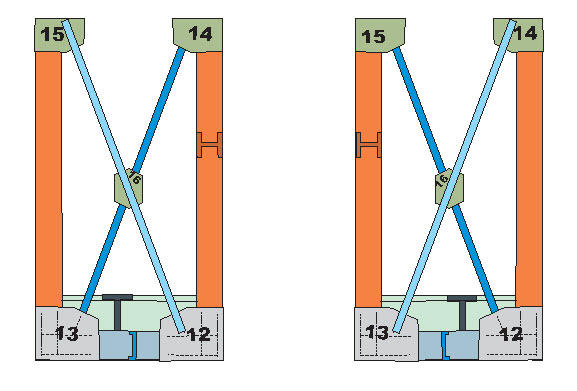

I have to leave a cavity surrounding the elongated ties that protect the moving points slide. I use a small brush and a tweezer to pull out any errant stones. The ballast on the edges is now level with the foam. I have to decide what kind of ground cover I'm going to use for the rest of the yard.

I have a problem with my Gloor Craft coaling tower. It has the wrong track spacing to cover the two tracks for which it's designed. The outside track would be under the coal chutes, but the track running inside should be where coal is brought to the station. When I put it on the track it's just too tight. I can put it on the outside, but then there's no track to bring coal. I'm not going to spend the money for another Ross switch to create a spur to feed it, plus I don't have the room for that track if I want to have space for the water tower and sanding station.

It's the catwalk that's causing most of the problem, but you can see here that this station is design for at least a 5" track separation. As it is now, the chutes will dump their coal into the inter-track area next to the tender. I can make due if I remove the catwalk or raise it above the height of the tallest locomotive (4" or 16 scale feet). Or I could design and scratch-build my own to accommodate the 3.5" track spacing created by laddering the Ross #4s. Or I could use this tower as a basis and kit bash one with the correct spacing. Any suggestions?

Attachments

Attachments

Jim, that's exactly what I'm going to do. I'm also going to revise the chutes to something like you did that's both more prototypically correct and will drop coal over the center of the tender instead of 6 scale feet to the outside. I also have to add concrete feet (again like you did). This will raise the building a bit higher which would be a good thing. I built this model in 1997 in a furnished rental apartment in Cincy, while working on a SAP project with Henkel. I bought it from Golf Manor Hobbies which is no longer in business. I also bought the Tudlow's Confectionary Steam Era Structures kit. I didn't have a running railroad until 2000 while in Germany, but had no landscaping on it. It wasn't until now that I'm actually reaching a point to start adding the buildings and structures that make model trains really interesting, (IMHO).

Today, I finished all the ballasting (hooray!) with the completion of all the yard ballast. I still have to do ground cover for this huge area (among other huge areas), but this was a major step. When it's nice and dry, I'll go back and check for loose areas, and after drying again, re-air brush rust on the rails and shoot some weathered black down the centers of all the tracks.

It took about 125 lbs of "white" roofing granules for the whole layout, plus an additional of 2 jugs of W-S black Coarse Cinders, 2 Jugs of Dark Brown and anything else I could find.

Now I have a decision to make... I have several directions I need to move, but not at once. There are two river valleys and three bridges to build. There's a nice sized mountain that will consume 4 tunnel portals, and then there's about 8 square feet of elevated portion over the return loop circle that will be the base for the town. Each of these areas represents a significant amount of work. Then there's the general contouring of land and ground cover as a result of using "cookie cutter" construction that leaves some open areas around track.

Like everything else on this large layout, everything is costing $$$. I'm thinking about building a master and making my own portals since 8 of them will cost about $160, an I still would have a mountain to build.

I already had the Plastruct bridge kits so I think that should be next. I was hoping to buy a NWSL rivet press setup, but I don't think that's going to happen soon.

Attachments

Based on Jim's good advice, I've been working these last weeks on modifying my Gloor Craft Coaling Tower which was the first structure I built in 1997 and has never been on a layout. In addition to scrapping the catwalk that was blocking access to the tower with tracks at my 3.5 inch spacing, I also went much further. I've redesigned the chutes and their suspensions, added lighting, replaced broken ladders, and added "concrete" footings under all the timbers. I've been writing about this whole process to submit as an article to O'Gauge RR magazine. This is based on a comment made by Alan that I should considering writing some of my learnings into an article. If the story isn't accepted, I'll publish it as a build thread in this forum. Here's a teaser...

The chutes now drop their load directly over the center of a tender sitting below them. The pulleys are home made and the right hand chute is able to raise and lower correctly. The left hand one is not movable due to a pulley that has a slightly undersized upper clearance so the chain doesn't pass through smoothly. All redesigns were done on the computer scaling them directly on the picture I took of the problem. The chutes are made of styrene sheet.

Attachments

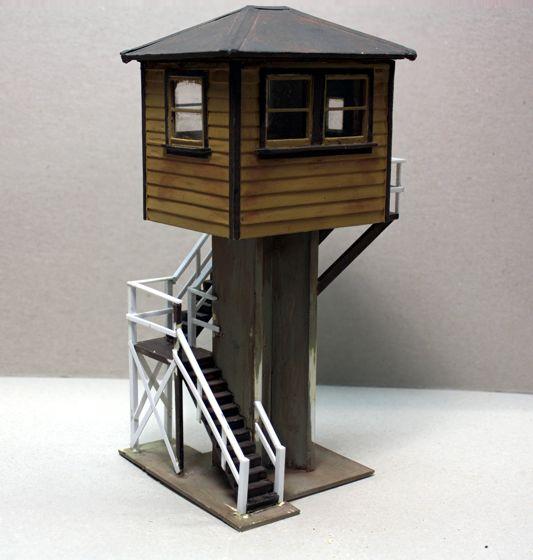

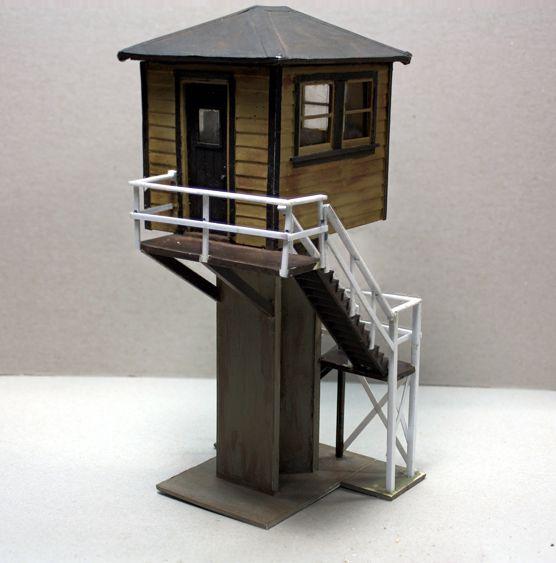

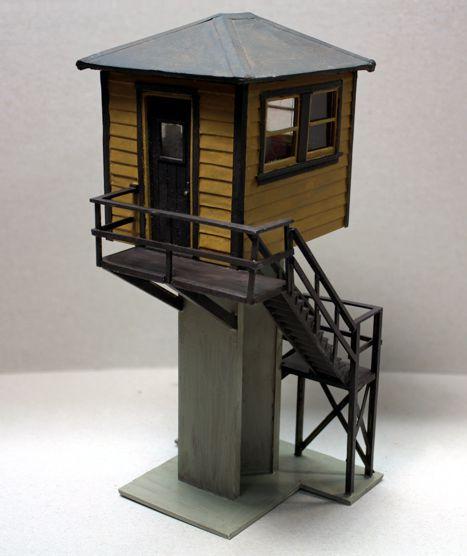

More on the Guard Tower.

Some of the rails had a nice chance to dry overnight so it was much easier to handle them to set up for gluing. I finished putting up all the rails and let it all dry a bit before painting.

Only the stairs, platforms and one pole remain from the original model.

Instead of painting just the rails, I decided to repaint the entire structure. I wanted to match the brown previously used so I mixed Tamiya flat brown with black until it had the correct value. I did all the painting by brush since it would have been very difficult to mask for the air brush. I used Model Tech concrete grey for the pedestal and base and again mixed Tamiya flat yellow with brown to get that mustard yellow. I haven't weathered it yet and I'm still deciding on what to do there. It really depends on where I want to put it. If it's near the engine service area, it should be pretty grimy, but if it's protecting a crossing near town, it could be much less worn.

As noted in yesterday's post, I inserted a grain-of-rice bulb into the bottom of the house, twisted the wires and then CA'd them to the pedestal. After I painted the wires they're very unobtrusive.

This reconstruction was a nice two-day project. I was actually thinking about throwing this structure out when it started falling apart. I'm glad I didn't and took some time instead to rebuild it.

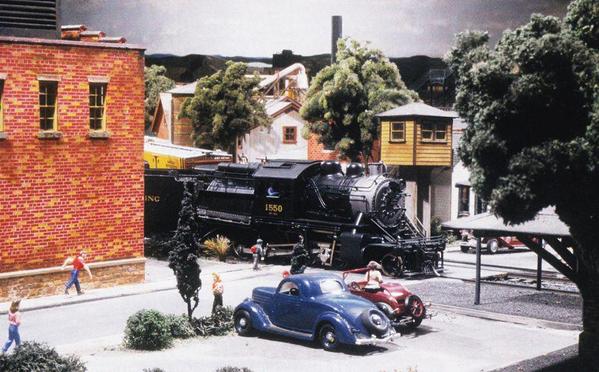

I located my copy of Great Model Railroads 2005 and found the article about Frank Miller's layout in Yardley, PA where this little building was installed. I bought in 2006. Here's what it looked like when situated on Frank's layout. Frank was a home builder before retiring and did some great structures. Unfortunately, I got to his house at the end of the sale of all the stuff and there wasn't much left.

I think I have enough latex layers on the footings master so tomorrow's work will be to see if I can actually get it off of the plate glass I use as a support base and pour some footings.

Attachments

I've started putting some buildings into the layout starting with the engine service area. It includes a Model Tech Sanding Tower, the Gloor Craft Coaling Tower now modified for my track spacing and a (I think) Gloor Craft 50k gallon water tank. The tank was one of the three buildings I purchased from Frank Miller. Since all three were on the elevated foam section, I use three different means to attach them to the layout. The sanding tower was built on foam core that was about an 1/8" lower than the surrounding foam so I spaced it up a bit with some cardboard.

After positioning and marking the location on the foam, I used a utility knife to cut the foam down to the OSB. It meant disturbing some of the ballast, but that's okay since it will be replaced up and over the sanding tower's base. I then used regular hot glue to hold both the cardboard spacer and the model. After gluing the model's base was just a little proud of the surrounding foam so I went back and used some light spackling compound to level the area. When it was dry I lightly sanded the area and then used another light coat to finish the job.

This picture shows the cardboard already in place.

For the Coaling Tower, I first glued the plaster footings to the legs of the tower, and then glue them to the foam using hot glue, but it didn't work in this case. I then went back and used Titebond wood glue on the plaster to foam and CA for the legs to the plaster. I then when back and filled all the gaps with DAP filler in a tube. This product is very fine grained and goes on pink and turns white when dry enough to sand. After it dried I cleaned it up with a sanding stick and then went back and added a second coat. This should that coat drying.

I'm going to go back and paint the footings and then ground cover and coal debris with clean it up. Of course I'll post pictures of the finished product.

For the water tank, I used adhesive caulk to hold the footings to the foam. I went this route since I wanted something that was flexible so if it got bumped it wouldn't break free. I made sure it was paintable before using it.

With these in place and their plaster drying I added one more building, the Model Tech Inc, signal tower. This fell in an area that was half foam, sculptamold and then OSB. Again, I cleaned the area, marked out the location by tracing, and then start cutting. In this case, I again used hot melt to hold the model to the table, and the Sculptamold to contour the area into the surrounding terrain. I'm going to have a drive leading up to this building as well as some form of roadway/gravel to the yard buildings.

Here it is in place:

Here's the contouring putty in place and drying. Sculptamold takes days to dry enough for painting and recoating with skin coat. It will need another coat to make it more "driveable."

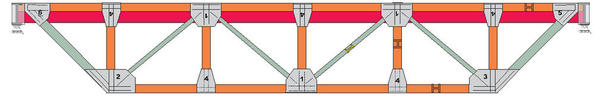

While all this is drying, I was redesigning the truss bridges for the last time before beginning construction. I'm glad I did since my first attempt have way too many errors which would have been disastrous. Since the bridge will be a deck truss instead of through truss, it can be much narrower and have less truss depth since trains don't have to fit inside of it. Here's the design in elevation and plan. There will be two of these bridges at slightly different elevations. One will be on a 2º slope.

The bridges will be 30 long. These were drawn in 1:1 scale in CorelDraw. The bridge will be built directly over the plans, model RC plane style. I find the Plastruct's instructions to be awful since no full-size diagrams are shown in O'Scale and therefore you must use the cutting table to measure and cut all the members. It's much easier to put the parts directly over the plan, mark them, cut them and then hold them to the plan during gluing. Since I can't print a 30+ inch paper on my printer, I print it as "tiles" and then tape them together. Not elegant, but it works. I suppose I could take it to Kinko's and have them print it out on large paper...

Side Elevation

Bottom (top is similar, but has only four bays

End Elevations, True projection. Not, you can use full cross-bracing on a deck truss since nothing must pass inside, unlike a through truss.

Changing the height and width of the truss changed every gusset plate in the model and required the most redesign effort.

I still have to figure out what kind and how I'm going to install a catwalk on the side, but this is not necessarily required.

I'm also starting to think about building a 36", 3-bay engine house. It will be scratchbuilt since nothing like this exists on the market. While I'd love a roundhouse and turntable, the layout (as it stands now) can't handle one, nor can the budget handle the cost of a turntable. I probably can swing a cool engine house.