Congratulations Myles. You should have come over and said hello. I am only about an hour or so north of the ship.

Thanks Al! We do have to figure out how to actually meet one another. Mark Boyce and I met at a service station outside Pittsburgh when I brought him the Idaho Hotel.

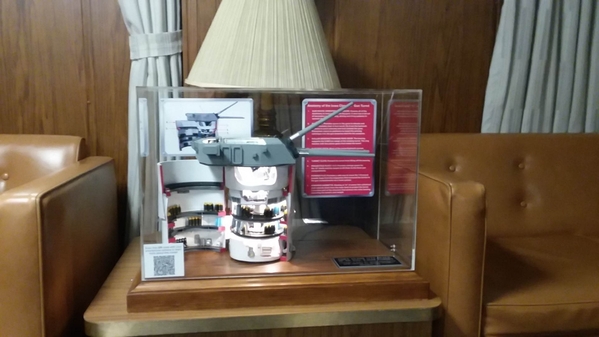

The model is on display in the New Jersey, but not in its final position. The ship is closed until March and they were having a board meeting. Ryan put it on temporary display on an end table in the ward room. It's final spot is shown in the images. I was concerned that the end table was not a secure enough place and Ryan already knew that. The board members were impressed and surprised since they did not know I was building it.

He's also going to get pics with better image quality for me.

Attachments

It was the best of times, it was the worst of times… Seems like I read that somewhere.

I finally got to First Build last night to start laser cutting the parts for the hardware store project. So that's good.

The CorelDraw file coversions to Adobe Illustrator worked well. So that's also good.

When I got there, all the stock that I was planning on using was no longer available AND they really don't expect to get any more. That's bad.

So I chose to cut the walls out of 1/8" white Plexiglass, this required spending time on my laptop changing some dimensions to accomodate the reduction from 1/4" to 1/8" stock. That could be okay

Then I started running the machine on the piece of 1/16" ply for some of the thinner parts. After over an hour of screwing around, it ended up cutting the bricks and engraving the outer cut lines. And it was horrifically slow. That was really bad!

So after spending three solid hours there, I got one totally useless part cut out of the dozens needed. That's also really bad.

So where am I?

First Build has two industrial-sized 2' X 4' laser cutters: #1 and #2. I was working on machine #1. The fellow assisting me, Jack from GE (they own First Build), said one of the machines wasn't working so well, but he wasn't sure which one. Maybe my troubles were because it was this machine that wasn't working so well.

First Build has been focusing more and more on making prototypes for GE Appliances (HQ'd here in Louisvile) and, while the Makery is still open to the public from 5 to 8 on weekdays, they are paying less attention to it than before.

I have these options open to me going forward on this project.

1. Continue to go back to First Build and keep experimenting to get the settings right and cut the parts out of Plexiglass including brick engraving.

2. Cut only the outlines out of Plexiglass and use Plastruct Brick Sheet (like I did in Nighthawks) and eliminate engraving all those bricks.

3. Go old school and cut the walls out of styrene sheet and build the structure with Plastruct brick sheet. This works, but not as cool as laser cutting.

4. Find another outisde vendor to laser cut the walls. Stepehn Miley at Rail Scale, doesn't seem so interested any longer to do custom jobs.

I have another reserved appointment on Monday night. I'll give it one more shot at First Build and then decide which option to take.

As usual, I will keep you all posted.

That’s a bummer. We will be here to see how it goes Monday.

I've submitted some drawings to Allen Goethe at Twin Whistle for a cutting quote. His does his cutting on 1/8" acrylic too, so the resizing I did last night wasn't wasted. We'll see how much the damages are. If I have to make a bunch of trips to U of L and do it at night which does not sit well with the boss, buying the cutting is not an issue.

Some progress to report! Allen Goethe of Twin Whistle is finishing up laser cutiing all the flat parts out of acrylic and and styrene including engraving all the bricks. Meanwhile, i didn't sit idle. I reviewed the architectural parts that I had previously printed with my old Elegoo Mars. I found that some could benefit from reprinting.

On the long roof cornice, my old printer required the length to be divided into thirds, making for more warping and joints. The new printer could do it in two parts. I redrew the parts and reprinted. i also redesigned the junction key making it tapered so it would engage with the female opening better. I reprinted the end details on this assembly also. In all of the cases I was able to position them on the machine to minimize any supports in the detailed areas.

I also joined the previously printed large lower cornice and corbel details. I thought about redrawing this to make it in two parts also, but it would have been more complicated to do so and I decided to use the previously printed parts. The slight warpage will be corrected when they're attached to the building and my resin mix does have some flexibility.

I then redrew and reprinted the window sill parts. The two store fronts have slightly different widths due to the intrusion of the door to the apartments upstairs. The original parts had supports in bad places and did not meaure up. I keep learning about printing and just the time that elapsed from the first printing and now taught me more techniques and enabled me to not have any supports in detail areas. So here are all the printed parts waiting for the building pieces. I expect that to be sometime in the next week.

I'm going to try a new way to do mortar lines. There's a water-based clay product that can be used as a panel line accept or weathering solution by Flory Model Co. UK. You brush or spray it on and remove the excess with a wet paper towel. You need to apply over a gloss finish and seal it with flat finish. I think it will be more forgiving and less labor intensive than using joint compound. We'll see. Right now, it's not carried by my local hobby shop, but they're checking to see if they can order it. Otherwise, I'll have to get it via Internet. They have more colors than this.

And I cleaned the shop! And boy, did it need it. I even took the shop vac to the work surfaces.

Attachments

Personally, I do not like the joint compound method to simulate mortar for the reasons you cited. I have gone back to the method you propose with other acrylic paint. It will be interesting how the Flory Models paint works for you.

Just paid for the laser cutting, so it should arrive sometime next week and then the fun begins.

The big problem with the joint compound is its abrasiveness. When you scrub off the excess, it tends to remove some of the base color as well, even though I'm using solvent-based base colors that should not dissolve in the water-based joint compound. I'm expecting that the clay product, especially after using a solvent-based gloss coat, should not remove any base. It seems much milder in its composition. We'll see...

Meanwhile, I have to buy a new inkjet printer to make decals for this project. Our only four-year-old HP printer simply stopped printing cyan. One page was full color and next all pink and yellow. I did all the tricks to reset it, including changing out the nearly new cartridge, and the problem persisted. I then tried one more time the next day. It printed one image with blue, the next image with the blue in stripes and the last image in pink and yellow again. It's not the cartridge… it's in the logic.

Anyone have any thoughts about this?

That’s great the laser cut parts are on their way to you.

I agree it’s not the cartridge. I would call HP technical support and see what they have to say. Hopefully they won’t tell you to try another cartridge. 🙄

@Trainman2001 posted:Anyone have any thoughts about this?

Yes:

Your cyan print head is clogged. Happened recently in our Epson printer. Google "Print Head Cleaning Kits" and you will drink from a fire hose. The basic idea is to use a syringe to force watered-down Windex through the heads until they clear. I used an old medical syringe I had around. Made the printer like new.

This can be something of a project, depending on your printer. Very likely, there are You-tube videos on how to do it for your particular printer.

P.S. -- This generally happens when you don't use your printer enough. I used to try to minimize my printing. Now I do the opposite. Paper and ink are less environmentally harmful than new printers.

P.P.S. -- If you do end up getting a new printer, the Epson ones with the huge ink tanks are da bomb.

HP's cartridges are sealed and have all the print jets and circuitry built in to each new cartridge. The first cartridge was just a couple of weeks old when it started and the second was brand new also. They were both HP factory OEM products. It seems weird that both would have failed Cyan jets. I hate coicidences. (that comes from watching hundreds of hours of great cop dramas).

I like the thought of Epson's tank system, but the base price of the printer is significantly higher than the base level HPs. I guess you pays me now or pays me later aphorism comes into play here. We print so little that the Epson tanks would last for a long time.

I bought a lower end (less features) Epson with the tanks a couple of years ago. One thing, the ink seems to last a lot longer than the HP cartridges for similar price. I think you get a lot more ink. I haven’t had any problems with any clogging.

Mark:

We must have bought the same printer but with different results. I have had horrible luck with both Epson and HP. I think that they were designed to be used much more than I use them.

Miles: Try cleaning the print heads as someone above mentioned. I am currently trying to revive another printer and I think cleaning the print heads is the answer.

I really following your builds.

@Trainman2001 posted:HP's cartridges are sealed and have all the print jets and circuitry built in to each new cartridge. The first cartridge was just a couple of weeks old when it started and the second was brand new also. They were both HP factory OEM products. It seems weird that both would have failed Cyan jets. I hate coicidences. (that comes from watching hundreds of hours of great cop dramas).

I like the thought of Epson's tank system, but the base price of the printer is significantly higher than the base level HPs. I guess you pays me now or pays me later aphorism comes into play here. We print so little that the Epson tanks would last for a long time.

As I understand it, only HP printers that have a single "tri-color" cartridge have the print head built into the cartridge. If that is what you have, I have no idea what is going on. If your printer has separate cartridges for each color, then there is a separate print head that can be cleaned. See this:

https://www.hp.com/us-en/shop/...w-to-clean-printhead

As for Epson: I have no idea whether these machines save money net. I love them because they are SO much less hassle to own and operate. Recommended.

Yup. Mine has the tri-color cartridge with the jets and circutry built in. Since both cartridges failed the same way, I'm still thinking it's in the printer. The odds of both brand new cartridges failing the same way (same color) would be very sllim indeed.

The Hardware Store parts are in shipment, and I actually got down and dirty and worked on that back road. There is a big gap between the foam core/illustration board road surface and the underlying layout. I decided to simply mix up some plaster of paris and soak some paper towels in it. It didn't have to be neat, and believe me, it ain't. It just has to raise up the road surface to be level with the rail head and provide some surface for the structural adhesive to hold.

I used my custom-made body support to reach over the delicate refinery and work behind it.

It worked pretty well… not perfectly well. Getting off the ladder I bumped into on of the pipe rack supports and did some damage.

After I finished with the plastering and mess, I went back and epoxied everything back in place. It's pretty solid now although it needs some paint to hide the shiny mess.

After putting down some plaster-soaked towels I put some weights on it so it would have at least some flat spots for the futhre adhesive.

After lifting the road surfaces I had some base for the adhesive. It's just holding a paper road so it doesn' have to be very solid or strong.

While this was curing I coated the road surface with some clear urethane to seal it from the water-based paint that I'm going to use for the coloring. I didn't do this with the city streets and should have. The water-based paint causes the surfaces to curl a bit. Tomorrow I will glue down the road and then use Sculptamold to taper the grade portions into the flat portions. I've used grouting tinted black before for roads and may do that again, or I might mix up some gypsolite and plaster it that way. It has some nice texture to it. By the time the road is done, the Hardware House parts should arrive. I will use spackling compound to transition the layered cardboard grade areas.

Later...

Attachments

The road sections look nice. So, I'm not the only one who breaks the models along the way. I'm glad it wasn't a lot worse!!

The parts are coming tomorrow. I decided to make an exploded drawing of the building to get a better idea about fits. I'm going to have some challenges regardless. Whenever you go from a SU drawing to a flat orthographic drawing you can miss things. It will all work out in the end.

And the rear

Onward and upward...

Attachments

First layer of plaster is on the road. I mixed some Woodland Scenics blank tint into some acrylic based grout. It was an awful operation! First the position of laying across my body support was not confortable and my back didn't like it. Then there was the slop. I persisted.

I used Loctite structural adhesive to glue the road pieces down to the layout. I put some weight on it till it set up. I then used the grout as a coating to blend the road parts into the layout. I made some filler strips for the crossing out of some left over MDF strips from the Engine House job. I used a narrow and wide putty knives to slather the goop onto the road. This was why I sealed the road surface so the water-based top coats didn't destroy it.

I broke a couple more refinery pieces, but they were minor and considering how I was going about this job, it was a miracle that I didn't wreck any more.

I used a freight car to double check the flange ways. They were clear.

I'm going to refine the surface a bit more with some tinted spackle, then paint with a darker gray to blend it into the existing road. I also delineated the parking lot at the headquarters building. There too I will be using some spackle to lay down a more road-like surface than the OSB layout sub-base. This road will have a dotted-white dividing line and have LED lampposts lighting the way.

I definitely know why I procrastinated on this job. It was distinctly not fun. Plastering is my least favorite model railroading task. Years ago, my now-grown grandsons would have tackled this job.

While I was doing all this, I was printing some more parts to the Hardware House. The extant structure has some very cute octagonal drawer units will all kinds of screws in them. I scanned these with my 3D scanning software in my iPhone 12 Pro and used the scan to draw a reasonably accurate rendition of them. They are mirror twins. I also drew and am printing (as I write all this) the L-shaped checkout counter that also has a zillion drawers in it. Both of these furnishing date back to the 1899 rebuild after the fire.

Here's the scan.

And here are the pair plus the missing attic vent that I needed to print. Painting those tiny brass knobs will be fun. I really don't know how much of the interior is practical. I have still images of a lot of the walls and some pano shots that could be put in to simulate an interior. If I do that, I'm not sure where the actual 3D parts are going to go. Meanwhile, I have options. If I really wanted to be anal, I could use the variegated coloration of the drawers and really match the real thing.

Attachments

Yes it would be handy to have younger grandsons. 😊 The octagonal drawer units look great, both the original and the printed ones.

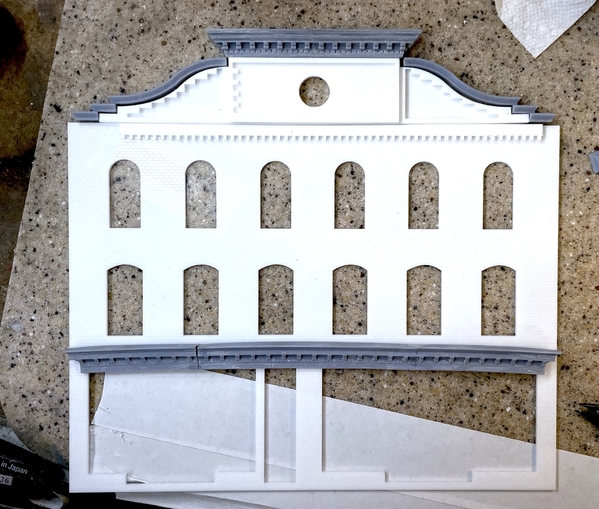

Work continues on two fronts. The Hardware House parts arrived and they're mostly okay. Allen didn't cut the four floor plates. That's not a show stopper since I can cut them myself out of other materials. More importantly, he cut parts out of 1/8" acrylic (actually .117) instead of 1/16" styrene. Adding to that dilemma, the corner brick trim stack was cut out of 8 identical pieces instead of the rectangular slot deminishing in length going back. It's supposed to create a brick stair step going deeper into the slot. That I can't really work around.

It's supposed to look like this...

The last challenge was the bricks on the attic portion of the rear wall not being engraved. That's another that I may not be able to work around. I've contacted Allen about these problems.

Regardless, it does look pretty darn good.

Here's a close up of the top trim fit.

I also got the skin coat onto the back road. Another messy job, but somebody's got to do it. All that's left will be a light sanding to knock off any high spots and painting can begin. I didn't have a center line on the existing road so I probably will leave it off here. Lots of plaster out of place that I will have to do some touch up on the rails and ties.

And of course Godzilla struck the refinery AGAIN. I shouldn't have fixed that on Monday. This time I even did more damage. I'm not going to fix it until all the back road work is fully complete! Eventually I will learn.

Attachments

In discussions with Twin Whistle on correcting the problems with the Hardware store. Meanwhile I'm still making 3D parts for the building. I created the L-shaped, old checkout counter with its myriad of drawers.

I may also 3D print the 1869 safe that the burglars tried to crack when they burned the place down in 1899. I'm also going to print the chineys. My first attempt at doing it in SU was a disaster. It's often better when a SU drawing starts going to the dark side to simply start over instead of trying to fix it. So I started over and solved another problem. When attmpting to print brick work that's on all four sides of an object, some of the supports are going to have to be in the bricks which makes a complete mess of those faces. No matter how you orient it on the machine some faces are going to be facing the build plate and get supports. It also exposes the leading edges of the bottom bricks to become islands thereby making sub-par brickwork. The only solution to that would be a support touching the lower corner of each brick… not possible. So I drew the chimney as a half object, divided on its diagonal. I will glue it together when printed and all the bricks are on top with no supports and all the supports are on the gluing faces that will get sanded flat anyway.

The one on the left is the correct drawing, completely solid with no hidden faces to cause trouble. The one on the right, while looking good, is a geometrical mess internally and wouldn't print well.

Here's the chimney (the building has two of them) oriented on the slicer as it will be in the printer. The joint between the halves will be almost invisible.

Having made this, I also have to make the brick pedestal for the corner roof decorations. I'm going to use the same procedure I did here now that I figured out how to draw it. The chimney on the Woodbourne Gallery I DID NOT PRINT this way and it was a problem to create it.

I got the road sanded, masked and painted. It was a real pain… literally… leaning on my chest on the stand I built made me sore, and sanding the road at arm's length didn't help either. Remember, I was 10 years younger when I started this ridiculous, endless project. I don't feel so bad. I'm following a build thread of a fellow in California who's building a 1:6 scale USAF A1-H Skyraider RC plane that is stunning in every measure, and he's build building it for 16 years, and he's not done yet. Good things take a long time.

Masking tape doesn't like to stick to freshly sanded plaster. I vacuumed it, then hit it with tack rag, but it was still very non-stick. I had to take special precautions when painting to brush away from the tape line towards the road center. Came out decently. I pre-sprayed the parking lines with Tammy White Primter and then masked them with narrow Tamiya masking tape.

Shortly after painting a mixture of white and black artist's tube acrylic, I pulled the tape revealing the nice line.

I have started doing the landscaping first with some ground cover, but then quickly realized it made masking even more difficult. So I stopped.

With all the tape pulled this is the road. Notice I got some white overspray on the lower portions of the office building. Ugh!

Still some work needs to be done on the crossing itself.

I also drew my own RR cross buck since the ones I have aren't so hot. I know you can buy these, but with my skills and tools, why not make them.

The cross buck scales at 4 feet square. I added a little meat to the post so it would print okay and stand up to my abuse working on the layout. It traced the font and spacing directly from commercial sign found on the Internet.

Here's how it's set up in the slicer. I'm doing it four up and I need four of them. I may print at least two runs because I have some other unprotected crossings on the layout. And I just thought of something… I didn't allow any length of the post for embedding the layout. I will do that now. Oh well… that's why it's beneficial to me to post all this stuff. I pick up a lot of things I need to do better on.

Attachments

Myles, I'm only seeing the last photograph, the drawing for the cross bucks. It sounds like you are making some really need items for the hardware store.

Myles,

I'm with Mark, can't see the photos except for the last one of the crossbucks.

Dave

The site timed out before I finished the post. I hate when that happens. Here's all the images kind of in reverse order from the post.

Attachments

I totally understand, Myles! It has happened to me. I really like the parts drawers unit. The diagonally split chimney makes good sense.

The road and parking lot look great! I can understand how it was difficult to do. I’ve been working on my little layout over 6 years and keep changing my mind. You are right, something good needs to take time. Well done

The chimneys came out as good as I could expect. The bricks printed perfectly with correct registation at the junction lines. Notice the change in design from the one I showed yesterday. This is actually the chimney's shape on the real building.

There was some slight warpage which created a visible gap and the joints.

With the help of some Bondic, I filled all the seams. It cures in seconds under its UV light source so I could immediately get to filing the edges and then recutting the mortar lines.

After sanding and recutting I have two very nice chimneys. Even with the little extra effort it was still vastly quicker than my brick-by-brick method I've used in the past. Because I chose to make them in halves on the diagonal, the flue goes entirely through. I won't have to paint e a black interior to simulate the depth. The depth will be real.

Using the same technique I created the shorter bases for the corner decorations. I measured the indented area on the decoration bottom and drew the brick pieces to match. It was almost perfect. I just had to add a slight chamfer to the bricks so it would slip inside.

I glued them together with thick CA and clamped them to ensure they were well seated.

I think these parts were the last 3D printed pieces I will need, but you never know.

As I noted earlier, the rear wall had a laser cutting error; the bricks didn't cut in the attic area. Allen and I spoke yesterday and he didn't have any more stock of that height. He asked if I could mail the piece back to him and he would cut the missing bricks. Instead, I've decided to hand cut the mortar lines. As I've started this, I wondering if I made the best decision. It's not easy. I started scribing them using a dividers to space the lines, but didn't like how I was aligning. I then switched to first delineate the lines with pencil and then engrave on those lines. I have a dental probe that I sharpened to a engraving point. The long lines are easier, but the cross lines are going to be a pain in the butt. This will be facing away from the visitors so any brick irregularities won't be quite so obvious.

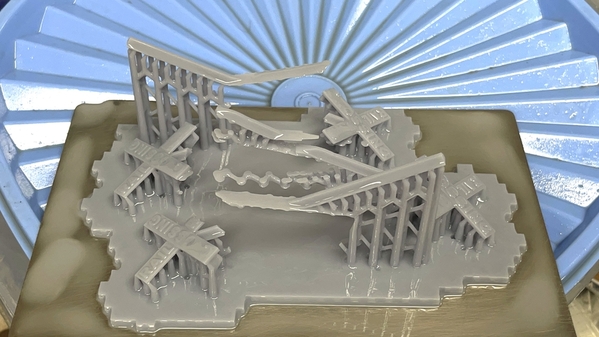

Meanwhile, my second attempt to print the RR crossing signs failed worse than the first. I had added some more beef to the pole, and changed the angle on the build plate, but this was what came out.

Not only did the poles fail miserably, the signs didn't do much better. The letter "C" was printing and when I checked the drawing it wasn't attached to the surface beneath it so no wonder it failed to print. It left some material stuck on the FEP surface. I finally had to clean out the vat and upon examination didn't like how the film looked so I spent the rest of the day replacing the FEP with a new one. That machine has only had two FEP changes in over a year. It printed ALL the turret prints with two FEPS. That's terrific!

I decided to scrap the printed pole and use some 1/16" metal tubing. This meant a slight re-design on the part and it now looks like this on the machine. It no longer has those long supports that are prone to breakage. I'm printing a lug on the back for the 1/16" pole. It's on the machine now and will come of in about two hours. We'll see...

I didn't do any more landscaping on the back road, but will pick that up tomorrow or Friday. We had an old Black & Decker Dust Buster in the Garage. We now have a newer Dyson in the house. I needed something smaller than my monster shop vac to pick up the loose landscape materials and remember this unused and always-charging dust buster and commendeered it for the basement duty. The suction was terrible so i opened it up to empty the reservoir, and then found that the intake chute was completely clogged. When I cleaned it out and vacuumed the fine particle filter the things sucks great! I used it to get up all the non-glued ground cover.

Until next time...

Attachments

I declaring the back road done… almost. I could still add some more robust ground cover and have to finish cleaning the track and installing the RR cross bucks. I repainted the road after getting all the ground cover in. The last thing I did was replace the disturbed ballast. I literally scaped the bottom of the paint can as I was totally out of the Behr Burnt Almond latex that I use for my ground base color and to glie the grass down.

I took a couple of selfies with me laying of that stool. I can activate my camera shutter (doesn't actually have a shutter) with my Apple Watch. I click it and have a 3-second delay to put myself in a more natural position.

From the side:

And from a train's eye view:

From the looks of the guy in these images, he's getting too old for this stuff.

I got perfect prints of the tops of the RR cross signs. I made the bore 3/32" for the pole. Thought I made it 1/16" but I was wrong. I have a bunch of 3/32 brass tubing since I use it for making drain spouts.

After sanding the support stubs I got 8 very nice RR crossing signs. They scale at 4' square which is the actual size of the sign I used to made the drawings.

Here they are on the poles, but some are upside down. I was doing this rushed at the end of the session. The fit is so tight, no glue is needed.

All that's left is the painting. I raised the lettering just to faciliate painting. I could have made some custom decals. That would work too.

Next session… put the refinery back together and finish the signs and install them on those back road crossings. I also need some on the unprotected crossing the town.

Attachments

I like the road. It looks like so many roads that cross the tracks with cross bucks for warning. The cross bucks themselves really turned out nice.

I’m with you on the selfies. My chest hurts just looking at you, and I know you have cushions.

Myles,

You look like a man on a mission. The roadwork and crossbucks look great.

Dave

A mission to an institution for the hopelessly adicted to building models… I think.

Short session today. Got the RR signs completed and installed and got the reprinted doors printed and ready for final cleanup. Their fit is better, but one is still loose. Since all the same door were created with the same drawing. I measured the door openings and there were size differences in their width. So it was either the laser cutter or my door drawings differed in size. I swear I cut and pasted one door opening to draw the other. Doesn't matter. I'll make it work.

Here's the signs painted. I painted the poles my galvanized steel color; aluminum mixed with flat black, and the raised lettering with flat black. Nice easy job… no hassles.

Drilled some 3/32" holes and just plopped them in without adhesive since the fits were nice and tight and nobody's going to be messing with them.

All the unprotected railroad crossings are now protected.

Tomorrow I will be repairing all the damage at the refinery and put all the materials away.

I'm also going to be starting assembly of the hardware store.

Attachments

They look great on the layout!

Myles, Your shot of upside-down crossbucks brought to mind a situation that happened on a tourist/shortline I worked on quite a while ago, prior to my retirement. Names are omitted to protect the guilty/innocent.

Our crew was replacing crossbucks in a state DOT program to upgrade to modern reflective crossbucks. I was sent out to evaluate all the crossings on the said railroad. I still have all my notes from that evaluation.

To progress, after receiving the required materials for this program, we were busy installing these units. Many of them had to have the posts replaced with treated 4X4's to comply with state regs for breakaway protection for highway traffic.

On one of the last crossings we worked, a co-worker and I had just completed erecting the post. While I was finishing tamping the post, my co-worker was putting on the crossbuck. I stepped up the street to see if our work was right.

I came back and said to my co-worker, "What is daor liar gnissorc?" My partner looked confused and then looked at the sign. Yep, upside down! A short embarrassment, removal of two lagscrews, and things were right once more!

So I guess the moral is, there's a prototype for everything! (Sorry about the thread drift. Excellent work on your modeling, by the way.)

Don Francis

Thanks Guys. I have no issue with anyone hijacking the thread as long as it's interesting. And your's was.

As all of you that have followed this saga for years know, on exercise days, I don't get too much done. Today was one of those. But I did do some stuff. I got the road build site cleaned up and all the tools, bottles of ground cover, glue, etc. put away. The ladder and body rest were removed. I vacuumed up the remaining junk laying around and removed the pipe support back to the shop to start the rebuild.

I'm using gussets to refix the columns to the lintel. This is the way it should have been done originally. I'm letting it dry overnight and will then try and match that Sinclair dark green that i used.

I cleaned up the tank car that I used to test the flange ways when doing the plastering of the new crossing. They were full of dried plaster and had to be fixed. I then ran a real train back and forth across the new work to make sure that electrical conductivity wasn't harmed with all the slop. It worked okay.

I then did a little job that's been bugging me for years. My H8 Allegheny's tender had lost most of its skimpy coal load. I had the coal and just needed the concentration to actuall fix it. I also applied some Tamiya gloss clear "smoke" around the water hatches to simulate a wet deck as would be case after a filling. I don't know if this is correct and I may change it, but for now it adds some interest. My engines are getting old! (Like me). My first MTH engine was the Premiere GG1 in 1995 so it's 28 years old and still works perfectly. My 3rd Rail J1-a is also the same age and it too runs fine. In fact they all run fine. It speaks well of the modern generation of engines with the solid state controls. All of my 3rd Rail Engines date back to no later than the early 2000s. Honestly… let me know if this works or not.

Now that I'm building the Newtown Hardware House, my son suggested that I tackle the Newtown Theater. It was built as a movie theater in 1906. It still operates as a movie theater and we've seen films there.

Technically not Victorian, but cool all the same. According to Google earth it comes in around 40 feet wide and about 80 feet deep. it could fit on my railroad only if I sell more buildings. I'm not adverse to this because I really like having the unique scratch-built structures I'm creating. I would have to sell the remaing kit-built structures. These are:

Bar Mills Saulenas Tavern. This has a full interior including an upstairs bedroom. It was the 2nd structure I built for thre railroad.

Here's the hard-to-see interior. This predates resin and 3D printing.

The next is the Newtown Chocolatier, a Steam Era Structures kit, also with full front interior. This was a tough build and not laser cut… all old school.

And finally there's the Gravely Building… another Bar Mills kit. This one has NO interior.

I'd like to sell them all at once, but would entertain splitting them up. If there's any interest I will post them again on the FOR SALE forum. I have not determined a price yet.

Attachments

@Trainman2001 Nice photos. Those are really nice buildings. I may be interested in the buildings should you decide to sell them off. I have the Menards Camaraderie remarkably similar to the Bar Mills Tavern. I wonder if licensed or copied? Mine is a mess insides. These wooden building are works of art.

Attachments

Myles, I’m sure you are glad to have finished the road in the back of the layout!

Your son picked a nice building to suggest you model. It has an added value since you saw films there if you decide to model it.

Myles,

You have provided us with one heck of a journey in constructing your layout and all these fine buildings. As you said you are addicted to model building. You should do what we have been doing in the United States forever and tear down and replace as the spirit hits you.Your happiness shows in everything you have posted here my friend.Enjoy doing whatever makes you happy on your layout.

Bravo, Trainman2001! I am sorry I had not previously seen your postings here: you are doing fantastic work. I am especially impressed by the interiors, the hardware shelving and drawers, and that gorgeous Painted Lady house in white siding with blue trim. The house alone is eye-popping.

Thanks all!

Glad you found the thread. "The never ending story"

There's more to the "Painted Lady" than meets the eye. It is closely based on this masterpiece by Edward Hopper, "House by the Railroad", which itself was loosely based on a mansion in Haverstraw, NY (or so the story goes). It took artististic license since so much of the Hopper work is obscured by his American Impresionist brush strokes and we're only seeing the house from one vantage point. It took as long to get the drawings right as building it. There are three different window frame styles and I had to master drawing all of them on SketchUp. I chose to produce the cupola windows and roof as a single 3D printed part. My original Elegoo Mars Classic was too small to handle this large part, so I had it printed by a colleague who was the manager of the University of Louisville's Advanced Manufacturing Institute. He did it on a larger FAM (string printer). For some inexplicable reason, U of L chose to shut down that operation and lay off my friend, Ed Tackett. My new Elegoo 3 printer has the capacity to do this large part.

I got the refinery fixed and it's back in service. My reinforced pipe support is better than the others. All the pipes were reattached and some needed to be drilled and pinned with 1/16" brass rod where the pins broke off the connectors. Some of the pipes could use a new coat of paint and some of the chainlink fence verticles need reattachmeent. In this view you can just see the road in the back. I'm actually happy that the only thing I broke was something easy to fix and right up front.

Here's another project that's under way, Edward Hopper's "Early Sunday Morning". This is purported to be a street in NYC. I scale it out to about 90 feet so it will fit in the space left by removing Saulena's. I started the drawing process by scaling the picture and having it overlay the SU drawing. I moved it off the drawing for this image. 3D printing the barber pole will be fun. The central door that's not recessed as far as the others I believe is the access to the upstairs apartments.

I will post this now, but I have another thing to add, and I'll update later. I'm back! Just had a nice late afternoon/early dinner at Sergio's World Beers. This hole-in-the-wall (literally) is a national treasure. Sergio is a Brazilian transplant who owns a bar/store that has in inventory 1,000 different brands of beer from all over the world. He has at least 50 on tap, plus aisles and aisles of refrigerated display cases. The front of the store has no name. The windows are boarded up. When you walk in you're greeted with an interesting place with a tin ceiling and bar with all kinds of snack foods in containers on it. He has a kitchen and regular seating in rooms in the back. It's basically a modified Louisville shotgun house that 15 feet wide and 100 feet deep. He makes a bona fide Philly cheesesteak in the tradition of the best in Philly, like Sonny's Steaks on Market Street in the Old City. He used fresh slice ribeye steak (just like Sonny's) on a real Italian steak roll. Along with that I had a very interesting Belgian Chocolate/Cherry beer and my wife had a German wheat beer Wienstehen.

The last thing I wanted to note was the products Ed Tackett is producing after his layoff. He tarted his own company 3D printing interesting and useful accessories to us model makers. These are neat racks to hold the small dropper bottles (like Vallejo paints) on standard peg board. Two come in a package for $6.00 and I bought two packs. They solve a problem for me. These things are always falling over in the drawer where I kept them. Now they won't go anywhere. They're neat because they doesn't take up precious work surface space.

According to Brian Bunger, Scale Reproductions, Inc.'s owner, Ed got another fulltime job with a German company so he may or may not be keeping his cottage business going.

Have a happy rest of the weekend.

Attachments

Here's the images of the Gravely building. I'm asking $395 for this one. All these buildings are in the "For Sale/Trade" forum.