I would like to convert an MTH PB dummy from 3 rail to 2 rail scale. Is there a kit for this? Does anyone do this? Any advise is appreciated.

Replies sorted oldest to newest

The dummy would be easy. You buy six 40" wheelsets, drill the sideframes (carefully - all holes must be in line, and dead center on the simulated bearing cap), drill and tap a bolster to hold the side frames, and mount to a plastic body bolster attached to the steel floor.

There are folks who do this kind of work, but it is far cheaper to buy a scale wheeled MTH set. It might be cheaper to buy a used Overland or Key.

Mark this date in history. I disagree with Bob2 for the first time on converting an MTH locomotive.

MTH PA/PB's don't use the interchangeable wheelsets, so your most efficient alternative for a PB dummy is to get the Northwest Short Line wheelsets (40") and use those. Normally, on most MTH diesels, the trucks are turned backward on the rear so you have to make sure the insulated wheels are on the same physical side of the chassis, but with non-powered units, the motor block is replaced with a plug. If that plug is plastic, then the trucks should be insulated from the steel chassis. Check that with an Ohm meter.

Bob makes some good comments, but the "easy" part ain't one of them (sorry Bob ![]() )

)

I tried to convert two RailKing F3 trucks to 2-rail, going by an article in another magazine. Now all I have is a basket full of unusable parts. You really need a proper machine shop to do this procedure with all the tools, bits, and equipment required. Things like pullers, reamers, and correct diameter drills for this task are things most model hobbyists don't have on hand. Sure you can buy them, but then you have to have the proper equipment and know-how to use them. A hammer, 1/4" drill bit and a vise are not going to do the job.

MTH does make 3/2-rail engines that can be changed out, but one like the RailKing I had with encapsulated wheels/axles within the truck block are just too hard to do for a regular model RR hobbyist who is not also a machinist.

Matt thinks he is disagreeing with me, but he isn't.

I did not specify NWSL, because any scale 40" wheels will do. And all you need is a drill press, a good vise, a magnifying glass, and #s 43, 41, and 50 drills and a good 2-56 tap.

I don't do this work, but I have an MTH SD 9 truck pair already converted. If you want to roll on SD trucks I will trade you even. You still have to find the wheelsets.

MTH will ultimately redo these truck blocks, and things will get a lot easier. You do know that the early MTH PAs came in 2-rail? And that all their early Diesel wheelbases are incorrect?

I wouldn't have a clue how and still can't figure if the side rods on a steamer are insulated from each other (maybe they're not). How does a steamer get power from both outside rails.

On two Rail scale steam models standard practice is to insulate the driver tires on the fireman's side of the loco and the tender truck wheel sets on the engineer's side of the tender. Loco picks up power from the right side of the loco and the left side of the tender.

MTH does it a different way by using axles that are split and insulated between the drivers and all tires are un-insulated. This requires that crankpins on one side of the locos drivers are pressed into insulating bushings so that main rod/side rods do not conduct through the cylinder casting. I am not fond of this method but MTH probably does this so they can offer 3/2 mechanisms, although I do not think they offer a kit to convert a 3 rail steam model to 2 rail.

I was recently sent a new PS3 MTH WM H-9 lettered for the P&LE to re-gauge the factory installed 2 rail drivers. The owner indicated that the model bounced and derailed on his switches. Flange gauge on all drivers was narrow and did not fit in the NMRA wheel gauge. I relocated the drivers out to a correct gauge point and the model ran fine through my switches. Pilot truck wheel set and tender truck wheels were gauged properly.

Joe Foehrkolb

I am with Joe. I haven't a clue why MTH did it that way, and there is no way one of those things would survive around here. We have enough short circuits without the possibility that a side rod will short against something. My MTH Hudson got Lobaugh drivers.

Of interest - my gear ratio changed, so I just re-calibrated the white bars on the flywheel and got 4 chuffs.

The really nice thing - I have scale size cylinders and a tail beam! Happy.

The trucks on my MTH non-powered PA were just stamped metal, without bushings or bearings. I swapped out the center blind axle for a flanged wheel set, but I'm wondering how you can do it. I would assume that the non-powered PB would have the same setup.

Bob, what do you mean by "no way that thing would survive around here."? Do you mean it would get worn out or that you dislike the design so you decided to improve it?

bob2 posted:Matt thinks he is disagreeing with me, but he isn't.

Phew! That was a close one. I retract. ![]() On another note, I too don't understand why MTH set their steamers up the way they did. Seems to me that setting the locomotive up as a 2-rail locomotive and connecting a set of wipers off the insulated wheels to go 3-rail would have worked just as well. Insulated bushings on the crank pins represents a possible point of failure.

On another note, I too don't understand why MTH set their steamers up the way they did. Seems to me that setting the locomotive up as a 2-rail locomotive and connecting a set of wipers off the insulated wheels to go 3-rail would have worked just as well. Insulated bushings on the crank pins represents a possible point of failure.

When a model comes in with features I don't care for, I fix it or get rid of it. I chose to fix the MTH. It took some belly stitching too. I am still working on tender pickups. Matt is going to do a factory reset for me some day.

bob2 posted:When a model comes in with features I don't care for, I fix it or get rid of it. I chose to fix the MTH. It took some belly stitching too. I am still working on tender pickups. Matt is going to do a factory reset for me some day.

E-mail me off-list (E-mail link in signature). I'll let you know next time I'm headed down to San Diego and I'll bring my gear. I'll also bring my Big Boy along for a trip around the 2-rail layout.

Guys, thanks for all the ideas. I had hoped there would be a simple conversion from 3 to 2 rail. However, the truck assembly has three parts (main body, left sideframe, right sideframe). The wheelsets are press fitted to bearings inside the main frame. Also, the axles are much thicker than the nwsl wheelsets I've seen. I have contacted MTH to see if there is a conversion kit available but have not had a reply to date. Unless a kit is available this looks like a project beyond my skills.

george bissell posted:Guys, thanks for all the ideas. I had hoped there would be a simple conversion from 3 to 2 rail. However, the truck assembly has three parts (main body, left sideframe, right sideframe). The wheelsets are press fitted to bearings inside the main frame. Also, the axles are much thicker than the nwsl wheelsets I've seen. I have contacted MTH to see if there is a conversion kit available but have not had a reply to date. Unless a kit is available this looks like a project beyond my skills.

Joe at Baldwin Forge might be able to help you with this. I'm pretty sure I saw NWSL wheels specifically bored for MTH axles in their catalog. If your PB is older, the inner axles (closest to the tank) were the ones with plastic blind wheels which are a bit easier to deal with. The driven axles are the ones that are tight and you need one strong gear puller to get them off.

rrjjf posted:On two Rail scale steam models standard practice is to insulate the driver tires on the fireman's side of the loco and the tender truck wheel sets on the engineer's side of the tender. Loco picks up power from the right side of the loco and the left side of the tender.

MTH does it a different way by using axles that are split and insulated between the drivers and all tires are un-insulated. This requires that crankpins on one side of the locos drivers are pressed into insulating bushings so that main rod/side rods do not conduct through the cylinder casting. I am not fond of this method but MTH probably does this so they can offer 3/2 mechanisms, although I do not think they offer a kit to convert a 3 rail steam model to 2 rail.

I was recently sent a new PS3 MTH WM H-9 lettered for the P&LE to re-gauge the factory installed 2 rail drivers. The owner indicated that the model bounced and derailed on his switches. Flange gauge on all drivers was narrow and did not fit in the NMRA wheel gauge. I relocated the drivers out to a correct gauge point and the model ran fine through my switches. Pilot truck wheel set and tender truck wheels were gauged properly.

Joe Foehrkolb

Wow! thank you for the info... gregg

That is why I suggested 40" wheelsets. You throw the blocks away, and have a real truck, supported by the outboard journals, and the sideframes go inboard for a more scale appearance.

NWSL does have a conversion kit - all you do is press the tinplate wheels off and the new NWSL wheels and axles go right in. The only problem is - to get the old Chinese wheels off is technically difficult. The Chinese have a new and better idea for press-fits! Removing them is a serious job for an arbor press and a special fixture.

I have removed hundreds of three rail wheels from MTH axles. The older MTH trucks, which were not made to be easily convertible to 2 rail, have axles that measure 3/16" in diameter. I have been successful in getting the wheels off by using a ball pean hammer and 5/32" pin punch (not a pointed tool) to break the inertia of the axle/wheel fit and getting the rear of the wheel far enough from the truck block to fit a wheel puller onto the assembly and finish removing the wheel. This can be a frustrating experience. Whatever you do, do not use a pointed center punch to start the wheel off. I had a customer who tried this before he sent the trucks to me. He spread the axle diameter and the wheels were locked on forever. I had to saw the axles out of the trucks and machine new axles from drill rod.

The plastic non flanged wheels installed on the inner axle of six wheel trucks are garbage and float in oval holes. I install 2-56 screws down from the top of the trucks above the oval holes to create an upper bearing surface for the inner non-powered axle and then install scale steel wheelsets with spacer washers (non conductive on the insulated side. The 2-56 screws create an adjustable bearing surface for this axle.

I drill and ream my insulated wheels to 0.249" in diameter and press a piece of 1/4" diameter Garolite (Micarta) rod into the wheel center. The Micarta is faced off, center drilled, pilot drilled and reamed to a tight fit on the MTH axles. I generally put the insulated wheels on the non-drive side of the trucks.

To avoid a short through the model's steel frame, I cut the frame in half between the trucks and use a non-conductive "gusset" to re-assemble the frame using 2-56 machine screws, four on each side of the saw kerf. If you are going to try this, locate the place on the frame where that saw cut will be made and install the gusset with 4 -2/56 screws on either side of the planned cut. Then remove the gusset and saw the frame. I do this with a horizontal cut off bad saw but it can be done with an ordinary hacksaw. The saw kerf will create a gap between the frame halfs. The gusset should easily re-attach to the frame sections and the frame will be the same size as it was originally.

If the metal fuel tank spans the gap, reinstall the tank with Nylon screws and insulating washers.

Before MTH offered their new convertible trucks I was 2 railing a lot of these models. It is a time consuming project that requires the use of machine tools to get it done right. If you have access to these tools, I encourage you to try this.

Most of my conversions now are primarily steam loco models that require machining new driver tires for the hi rail drivers.

Joe Foehrkolb

Baldwin Forge & Machine.

Joe, that is he most comprehensive set of instructions I have seen for this conversion, yet. Great job!

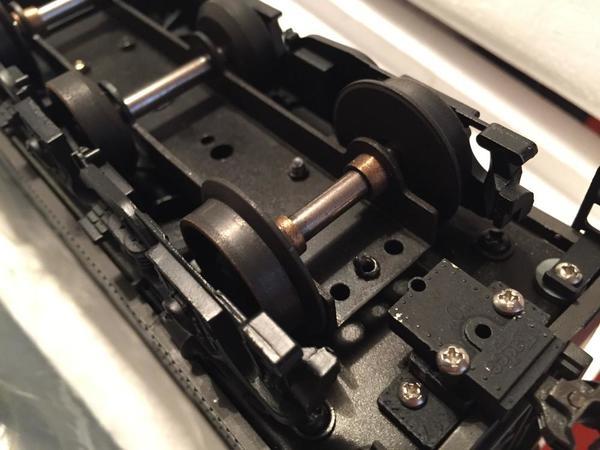

Here's the stamped metal frame trucks of my non-powered MTH PA. I kept the blind center axles, but on the powered PA I also added a flanged wheel set and a 2-56 screw "bearing" to hold it in place, just like you said!

Attachments

Would it be practical to use a torch to heat the wheel in order to remove it from the axle?

Maybe - but then you have to handle it to get the wheel off, and could get a serious burn.

Joe is outlining how to 2-rail a powered unit. I have 2-railed the similar but better K-Line powered truck, but never one of these. If you are two-railing a dummy, convert the sideframes to conventional 2-rail sideframes and throw the dummy trucks in the trash. Lots cheaper, and lots easier. See my first post.

Joe will still do this conversion for you, but there are lots of factory 2-rail PA sets out there, and you will be $ ahead selling yours and buying a 2-rail set if you are considering retaining the truck blocks and motors.

George,

I think I tried heat many years ago and found it not to be practical but you are certainly welcome to try it. As Bob Turner indicates above, unless you are prepared to deal with an extremely hot sintered iron wheel, you risk a serious burn.

Joe Foehrkolb

Sometimes you get good advice and avoid serious problems. This is probably one of those times. I thank you for your sage counselling.

George

George - I am in the process of repowering a pair of brass Sunset PA's and will soon have 2 pair of highly detailed sprung 2 rail lost wax cast PA trucks that will be excess to my needs. They currently have gearboxes on the axels but they can be removed easily. Contact me off list if interested and I'll send photos.

Ed Rappe

Joe. I quit! Screw adjusted bearings, that's a first for me. I always follow your posts with interest. Can't wait to see you in Lombard. bob2 is also an innovator, busy converting engines right and left.

Ed - which sideframes will you use - Sunset, or CLW?

And Central- if you buy the lost wax sideframes, consider me for the MTH castings.

Bob I'm using the Overland PA trucks with Jerry Snow drive. Both the Sunset and Overland PA trucks are good looking and solidly built. The Overlands had pickup wipers installed so they won in a photo finish.

Ed Rappe

I want to thank everyone for their suggestions and advice on this conversion project. The MTH wheelsets were almost impossible to remove. I elected to hacksaw them apart. I ordered and just received NWSL 40" shouldered wheelsets. These were installed in the MTH mounting. I used a brass tubing to go between the brass bearings as the NWSL axles were narrower than the MTH axles. I added plastic washers to insulate the wheels. I now have to shim the kaydee couplers to complete the job. I would have been nice if MTH offered a conversion kit. Anyway, as most of you know being a 2 rail O scale modelers is not as easy as our HO and 3 Rail friends. However, it is always great to know that fellow O scalers will generously help.

I can't remember if my MTH PAs had pre-drilled holes for Kadee mounts in the back, but this is what I used...

Since I lowered mine to the correct scale height, they used a 0.250" spacer on the rear. For the original factory ride height, or if you need to cut a custom thickness, you may need a thicker one.

Attachments

Thanks for the photos. I used styrene shims to bring the metal base up to the plastic hood level. Then I used six shims from Micro-Mart to set the kaydee at the proper level. I prefer 1-72 screws to the 2-52 but have used both. For looks and style your conversion beats mine. I hope the pictures in my attachments went through since I have not used this option before.