Does anyone know if Scotch Brite pads are good for cleaning tubular track, and will not damage the track?

Does anyone know if Scotch Brite pads are good for cleaning tubular track, and will not damage the track?

Super O Bob posted:Ron464nyc posted:Be awesome to run a $1000.00+ loco on lionel and not somebody else's track.

That is my point exactly...

Yesterday it was Addams Family Super O Layout... now we look to be heading back to ressurection of super o!

This topic used to come up about once a year. I have a barn full of super o in storage... literally hundreds of switches and everything. But if lionel ever did reissue it, or some NEW scale like track system, i would be all in..

Hey super 0 bob, have anything for sale? Enjoyed your topic and opinions so much I'm looking at all my 0gauge track and,well,got me thinking! I am curious though about the track to track connectors. Can the bus clips be solderd? Or is this really a non issue like roller wear.

BlueComet400 posted:If an extinct track system would ever be re-issued, why not the K-Line Super-Snap?

Already done HERE.

Ron464nyc posted:Super O Bob posted:Ron464nyc posted:Be awesome to run a $1000.00+ loco on lionel and not somebody else's track.

That is my point exactly...

Yesterday it was Addams Family Super O Layout... now we look to be heading back to ressurection of super o!

This topic used to come up about once a year. I have a barn full of super o in storage... literally hundreds of switches and everything. But if lionel ever did reissue it, or some NEW scale like track system, i would be all in..

Hey super 0 bob, have anything for sale? Enjoyed your topic and opinions so much I'm looking at all my 0gauge track and,well,got me thinking! I am curious though about the track to track connectors. Can the bus clips be solderd? Or is this really a non issue like roller wear.

HEY RON... I REREAD YOUR QUESTION...

I might have misunderstood. If you use original (not repro) bus clips and fit them properly (flush) they will not come up.

It is possible you might have a clip that was spread open and bent open slightly, and you and rebend it with needlenose pliars. But i have not encountered this. Normally they fit snug and stay in place.

Because of how good the solid copper center rail carrys current, i actually only wired drops to my track every 18ft or so! This is unheard of for atlas or gargraves because it is so much tougher to push current thru those other types of track. Usually they do drops every 6ft or less for optimim performance.

Even with the 18ft separated drops, i still measured a steady 18volts! I used the Super o #43 power track to hook my wires on. I used all solid core large gauge feeders and under table bus wires. My point with this is because the drops are so far apart 18ft separation, if any bus clips came up (they are every 9 inches or so) the trains would STOP. So they never did and i never had any issues with them popping up so they didnt need to be soldered. Realize i took care in fitting them down and filed the edges of the center rail notches so that the bus clips would fit flush.

So if done right, you dont have to solder them down...

I think it can solder. I solder my solid copper bus bar under the table to my drops to my #43 power tracks...

Yea i got stuff for sale... on ebay... i also will have a huge stash of atlas o freight cars to sell, those i will put up on the ogr buy/sell in a few weeks...

My dad had quite a few packs of those O27 transition pins. I always wondered why Lionel engineered those metal tail pins and metal rail pins rather than just mold them as round pins on the O & O27 sides. It seemed weird to stick in a folded flat pin into a round hole. What was up with that?

Hudson ron1956 posted:

"Hey super 0 bob...Enjoyed your topic and opinions so much I'm looking at all my 0gauge track and,well,got me thinking!"

_______________

Bob is very knowledgeable about Super "O" as you have clearly recognized.

And, as you can see, he's very generous with sharing that knowledge.

Arnold D. Cribari posted:Does anyone know if Scotch Brite pads are good for cleaning tubular track, and will not damage the track?

I’ve used it to clean all types of three rail track and had not had an issue. The caveat might be to not use it excessively. Once I’ve cleaned with the scotch bright, I’ll keep it clean with track cleaner fluid or a track cleaning eraser. Remember, some brands of track are plated and the scotch brite after excessive use will remove the plateing.

Steve

RideTheRails posted:Arnold D. Cribari posted:Does anyone know if Scotch Brite pads are good for cleaning tubular track, and will not damage the track?

I’ve used it to clean all types of three rail track and had not had an issue. The caveat might be to not use it excessively. Once I’ve cleaned with the scotch bright, I’ll keep it clean with track cleaner fluid or a track cleaning eraser. Remember, some brands of track are plated and the scotch brite after excessive use will remove the plateing.

Steve

Thanks, Steve. I will follow your advice and be "workin' on the railroad" tomorrow. Arnold

Dennis GS-4 N & W No. 611 posted:OGR CEO-PUBLISHER posted:I have used different kinds of track for many years from 0-27 to Super 0 as well as K-line, Atlas, Ross, and Gargraves ... you name it. I don't "clean" my track because I found out years ago that a spray of electronic cleaner properly spaced on the track keeps the trains running and the track "clean". I don't know why it works so well but it does and without gunk building up on the wheels or rollers. I know .... hard to believe but just try it, you may just like it! By the way, I love the look of Super 0 track and like several of you, had it been available in broad radius curves (commercially), I would have probably gone that route.

Alan

Alan,

Thanks for posting. Is there a brand, or brands, of electronic cleaner that you could recommend? Also, any rough estimation as to the "spacing" that you have found to be effective. This seems to be an excellent method for track cleaning.

In this regard, I am also taking notes as to the other methods suggested for track cleaning, including the excellent posts by Super O Bob.

Dennis....the brand I use is CRC. The particular product is called CRC 2-26 multipurpose electronic lubricant. I generally use it once per year and spray it directly (light push of the spray nozzle) on the middle track. Just leave a "line" of lubricant on top of the rail. You can also spray a small amount on the outside rails but just a little goes a long way. Do this every 6 or 8 feet. No need to wipe the track ... just run a locomotive around a few times and you are good to go.

When I didn't run trains every day, I could go a couple of years between applications but I run trains more often now so once a year seems to work fine. Honestly, you will be amazed at how well the trains run and the increase in reliability of the signals going to the locomotives....

Scotchbrite is an abrasive and will eventually wear through, but I can't think of a lighter abrasive pad really. It does have various grits as well, green kitchen stuff usually being a medium/light grit, browns get coarser. I've seen red and white both coarser and lighter.

Clips might pop up once a week, or once a year, or never. I don't think I've had one come up in two years now.

But if they do, it can cause "pole vaulting" of cars with pickups. I've had it happen about 4 times in the last 6 years.

The connection itself is great. So soldering one side, just enough to hold the clip level is really all you'd need. I've lost 3 clips that never resurfaced...? I just wrapped the spots with a cut tin can. It still conducts better than any track I own except maybe brand new O track. I just haven't measured yet.

Roller and shoe wear is not a non-issue on MANY locos. But I think it's worth it. I'd call it a minor issue. Easily delt with, but some folks are touchy on things like roller wear. I see rollers as a maintenance part that will have to be changed once or twice before the motor ever dies. (Like axle bushings, brushes, etc)

Some we're pretty bad, but I have new rollers that show what I know is Super O wear. Tube track center rail is wider, and the contact patch actually grows with wear and slows wear with more support at that area after wear.

The angles and edges of S-O takes a toll even though the center rail material is softer copper.

phrankenstign posted:My dad had quite a few packs of those O27 transition pins. I always wondered why Lionel engineered those metal tail pins and metal rail pins rather than just mold them as round pins on the O & O27 sides. It seemed weird to stick in a folded flat pin into a round hole. What was up with that?

I think because molded pins would be plastic and not carry current from the o gauge track to the super o outer rails... so the super o side needed to be a pin.

The pins also have a short section where they are raised up and act as RAILHEAD also because they fill the gap between the super o and the ogauge that is formed because the super o ties and o gauge ties prevent the rails from touching, there is a gap. So these pins also fill that gap and become railhead for about 1/8 inch. That contributes to the wierd shape.

So then to fill that huge hole in the ogauge track rail they just folded over the metal pins.

OGR CEO-PUBLISHER posted:Honestly, you will be amazed at how well the trains run and the increase in reliability of the signals going to the locomotives....

Alan... yes another great point... clean track really helps the robustness of command signal... and trackside signals as you mentioned. I highly recommend clean track...

On scotchbrite, that stuff is designed to strip the surface of metal to polish it. I rather use the abrasive pads that just clean gunk from metal and leave it clean. The pads work great and turn black with rail gunk and track remains clean and shiny.

I think its better to use than scotchbrite.

Adriatic postedClips might pop up once a week, or once a year, or never. I don't think I've had one come up in two years now.But if they do, it can cause "pole vaulting" of cars with pickups. I've had it happen about 4 times in the last 6 years.

The angles and edges of S-O takes a toll even though the center rail material is softer copper.

Adratic... if you have any pop up, it usually is the center rail has slid to one side. You can move the center rail about 1/16" side to side down length of track and get better fitment of the bus clips. Also use a small flat file and debur the edges of the notch and that usually fixes it. If they come up, it is because the notch may need filing and fitting. When flush you will not pole vault.

I have seen the edges of the center rail wear. The center rail has a flat on top then it drops off on edges. It seems to not mess with rollers because as i said, mecanically the steel is 3 to 4 times harder than copper. So that copper wears away not the steel.

I will look for some cabooses i have seen get copper rollers and take a pic...

We had train nights with a theme. Few times it was run UNION PACIFIC night. My cabooses would get a workout. I have lionel scale cabooses with smoke so they are pulling power, and ran for so much time they would see the most time on track. Not one has roller wear.

I am big UP guy, and run only freights, so these UP cabooses dont really ever leave the track. Its a good test...

Ok... i have a comment on wide radius super o track.

I know many will just try and get O72" curves and be good with that. But if you are bending your own, bigger is better. If you can fit it, i encourage o92" or larger.

I designed my original layout around 5 inch centers, that means each parallel track measures 5 inches from center rail of one to center rail of the other adjacent line. So i planned o72", o82", o92", o102", and o112". Then for really sweepy curves i have o134" and o144". As you know the measurement is the diameter of the circle. So o144" super o is a 12 foot diameter!

One thing i noticed (if you run long trains) is its best operation is around 092". It was still tight enough to get a good folded dogbone layout, but also permitted great train function. That is to say the freightcars stayed on the track really well with o92".

I cringe with o82" and that was the MINIMUM radius i would do in the tightest curves. From o72" to o82" was an improvement, but things got much better around o92" to o102".

So if you are pulling long trains, and can, i would encourage you thinking BIG and going to o92" or larger.

I built my current (new) back room layout (temporary) with 4.5inch centers. It looks better to me, and i did it for appearance.

However now with the 86ft box cars, and 89ft autoracks and 21inch passenger cars, the overhang can cause impact with big boys and articulated engines on adjacent tracks. Even with o92", big boys will hit the 21" pass cars and 86ft box cars in the turns.

So i an planning to tear it up and go back to the 5inch centers.

I am getting too old to remember what cant run on adjacent tracks next to big boys. And i dont want to tear up my trains. So i am going back to 5inch centers so i can run anything and not worry (because there is always at least one big boy on the layout).

So my best reccomendation is 082, o92, o102, o112 for mainline loops, that is 5inch centers... your choice of center to center distance impacts which radius curves you do (if you are keeping things square, without easements or lead in curves). K.I.S.S.

Arnold D. Cribari posted:RideTheRails posted:Arnold D. Cribari posted:Does anyone know if Scotch Brite pads are good for cleaning tubular track, and will not damage the track?

I’ve used it to clean all types of three rail track and had not had an issue. The caveat might be to not use it excessively. Once I’ve cleaned with the scotch bright, I’ll keep it clean with track cleaner fluid or a track cleaning eraser. Remember, some brands of track are plated and the scotch brite after excessive use will remove the plateing.

Steve

Thanks, Steve. I will follow your advice and be "workin' on the railroad" tomorrow. Arnold

I forgot to add and I think most would agree, NEVER use steel wool pads to clean track and/or wheels.

Steve

It is too bad no one has tried to expand the Super O assortment. I've always been a fan but like everyone else, was limited by the lack of larger radius curves and turn outs. I still have a small Super O layout that I use occasionally with my traditional trains, but I went with Atlas O in order to run my scale sized trains. Correct me if I'm mistaken, but I thought I remember seeing some black plastic Super O "test shots" surfacing before Lionel released FasTrack. There was some speculation at the time that Lionel was kicking around the idea of resurrecting Super O, but ended up developing FasTrack.

OGR CEO-PUBLISHER posted:Dennis GS-4 N & W No. 611 posted:OGR CEO-PUBLISHER posted:I don't "clean" my track because I found out years ago that a spray of electronic cleaner properly spaced on the track keeps the trains running and the track "clean"...

Alan

Dennis....the brand I use is CRC. The particular product is called CRC 2-26 multipurpose electronic lubricant. I generally use it once per year and spray it directly (light push of the spray nozzle) on the middle track. Just leave a "line" of lubricant on top of the rail. You can also spray a small amount on the outside rails but just a little goes a long way. Do this every 6 or 8 feet. No need to wipe the track ... just run a locomotive around a few times and you are good to go.

When I didn't run trains every day, I could go a couple of years between applications but I run trains more often now so once a year seems to work fine. Honestly, you will be amazed at how well the trains run and the increase in reliability of the signals going to the locomotives....

Alan,

Thanks much! That is an elegant solution to track cleaning, and will make the process much quicker and easier. I just ordered some and it should arrive in a couple of days. Among the other likely simplifications resulting from using this process is cleaning those harder to reach areas, or, areas with scenery close to trackside.

Dennis GS-4 N & W No. 611 posted:OGR CEO-PUBLISHER posted:Dennis GS-4 N & W No. 611 posted:OGR CEO-PUBLISHER posted:I don't "clean" my track because I found out years ago that a spray of electronic cleaner properly spaced on the track keeps the trains running and the track "clean"...

Alan

Dennis....the brand I use is CRC. The particular product is called CRC 2-26 multipurpose electronic lubricant. I generally use it once per year and spray it directly (light push of the spray nozzle) on the middle track. Just leave a "line" of lubricant on top of the rail. You can also spray a small amount on the outside rails but just a little goes a long way. Do this every 6 or 8 feet. No need to wipe the track ... just run a locomotive around a few times and you are good to go.

When I didn't run trains every day, I could go a couple of years between applications but I run trains more often now so once a year seems to work fine. Honestly, you will be amazed at how well the trains run and the increase in reliability of the signals going to the locomotives....

Alan,

Thanks much! That is an elegant solution to track cleaning, and will make the process much quicker and easier. I just ordered some and it should arrive in a couple of days. Among the other likely simplifications resulting from using this process is cleaning those harder to reach areas, or, areas with scenery close to trackside.

Personally ive had bad experiece with any kind of lubricant on outer rails. Traction tires and lubricant don't mix.

Train Nut posted:Dennis GS-4 N & W No. 611 posted:OGR CEO-PUBLISHER posted:Dennis GS-4 N & W No. 611 posted:OGR CEO-PUBLISHER posted:I don't "clean" my track because I found out years ago that a spray of electronic cleaner properly spaced on the track keeps the trains running and the track "clean"...

Alan

Dennis....the brand I use is CRC. The particular product is called CRC 2-26 multipurpose electronic lubricant. I generally use it once per year and spray it directly (light push of the spray nozzle) on the middle track. Just leave a "line" of lubricant on top of the rail. You can also spray a small amount on the outside rails but just a little goes a long way. Do this every 6 or 8 feet. No need to wipe the track ... just run a locomotive around a few times and you are good to go.

When I didn't run trains every day, I could go a couple of years between applications but I run trains more often now so once a year seems to work fine. Honestly, you will be amazed at how well the trains run and the increase in reliability of the signals going to the locomotives....

Alan,

Thanks much! That is an elegant solution to track cleaning, and will make the process much quicker and easier. I just ordered some and it should arrive in a couple of days. Among the other likely simplifications resulting from using this process is cleaning those harder to reach areas, or, areas with scenery close to trackside.

Personally ive had bad experiece with any kind of lubricant on outer rails. Traction tires and lubricant don't mix.

Well...with all due respect, you must not have been using a rubber/plastic friendly product. I have been using CRC 2-26 for many years ... more than enough time to find out if there is some kind of incompatibility. So ... like I said, try it, you may like it! AND, by the way, this particular product is designed to help prolong rubber/plastic parts. I have found that even if I put too much of it on the track and get some wheel slip, I just run the trains until that slip goes away. Plus, I don't have the dried out cracking tire problem that some folks have had. Never have had any bad interaction using 2-26.

But of course, you don't have to believe me ... I am just making my observations from a long time experience with this particular product. I can't speak about other competing products with which you have used.

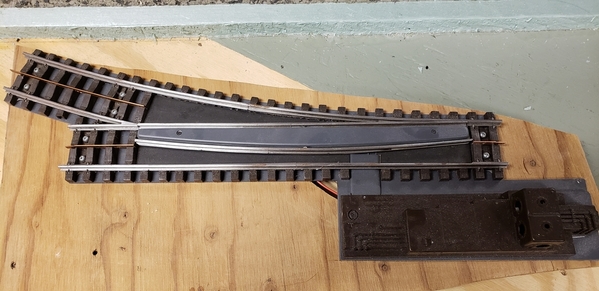

Bob, I have seen your switches in pictures in years past- how did you make them?

petrifiedagg posted:Bob, I have seen your switches in pictures in years past- how did you make them?

Hi petri... i basically took the idea Marx had for their switches and applied it to super o.

The marx switch has a unique frog. Depending on the position of the switch the one rail can be the center rail <or> the grounded outer rail. Polarity is flipped depending on the position of the switch. I will drop in a pic soon.

So i used the CAD system at work to figure out the geometry of where the rotation point had to be based on the diameter of the curve, so that the typical width roller on our engines would not fall off the 'center rail' depending on which position the switch was in.

The base was made out of model plane plywood and layered with counter top material so it slides well. The switches worked well. I used them for passing sidings and spurs.

I basically run 'cowboy' and just have separated loops with long trains and just let them run. I dont really do switching or trust any manufacturers switch with a $1000 engine and about $1500 in freight cars to not cause a derailment on a elevated line.

So i keep loops free of route switches and use switches only for spurs and passing sidings where i drive a train in or out and flip switch back to mainline loop running position.

I will put up some pics of marx. .

These are the marx switches that were the model for my custom super o switches. They are brilliant in that there is very simple geometry. The train doesnt know its going thru a switch. This eliminates all the usual guides and rail breaks in a typical switch and simplifies it greatly.

There is also a guy named Dick Reichart (sp) who was in the silver hall at york on one end who would sell switch building manuals, and he would do some amazing stuff...

Attachments

In 1957 I got my train- a bottom of the line 202 in o27. Then I got the 57 catalog and later the book “model railroading.” When I got my ping pong table Sears had a nice price for Super O. I bought enough track for an outside circle and used the adapter pins to connect to a switch to connect with my inside o27 loop and siding. I thought my 202 riding on Super O was just about the best looking train there was. While I was in med school in the late 60’s early 70’s I started acquiring Super O track and switches and had a fairly large layout. Since then I have acquired a number of engines, cars etc and have planned a new layout to be 8x16. Initially I planned on using Ross and Gargraves but I could never get past my love and identification with Super O. Then I decided to do Ross switches with SuperO bent to O72 and O84 and an inside yard half loop of O64 and O66- long story. I agree with Bob about even wider radius but I don’t have the space. I had talked with Len about bending the curves and he said he could but haven’t talked further. Obviously I would love Super O switches- I would need 072, O64 and standard 11 degree. I plan on using Dennis Brennan’s ballasting method for simplicity. Super O has issues but for guys like me who started with the 57 catalog- there is nothing better.

I dug thru storage and came across a custom O-134" super o switch with the motor flipped around for clearance on a spot on my old layout. Here is a pic...

The other switches are all still packed away, so this is one that was finished and not used before layout was torn down. They took a good 40hours to build.

You can see that similar to marx, the 'frog' is a one piece deal with rail stock on each edge. To keep it all super o looking, super o track was used in construction. This switch you can see is both the center rail and outer rail depending on frog position, just like the marx.

They worked really well before and i will use them again. As i said before, you could use lionel o gauge o72 switches with super o, as it was designed that way with adaptors.

For scale, here it is with a new vision niagara...

Attachments

Beautiful switches. Little sidenote. I thought I had seen that mechanism before so I pulled out my 1937 catalog. Lionel used the same mechanism for their O27 switches back then.

Bob,

Those look very nice and are impressive in their apparent simplicity, which is likely deceptive given the design process and fabrication time.

Does anyone know, in general terms, what tooling was likely required to manufacture the original Super "O"?

I am really enjoying this thread. My father built a 5 x 9' Super O layout for me for Christmas of 1960. My parents had stockpiled Super O track and switches against the time when we would move and my father and I would expand the layout. That never happened and the brand new Super O switches were stolen before they ever got used.

Over the years, the layout got damaged and was the target of a robbery (all of the accessories were stolen).

Last year I restored the layout and enlarged it to 5 x 13' (the largest practical size I could have in the available space). It did not even occur to me to use anything other than Super O track (I wanted to make it as it might have been if my father-now deceased-and I had expanded it together back in the 1960's.

The track diameter includes 036 (stock), 042, 048, and 054 (the largest that would fit and allow clearance between the overhang of the locomotives and the small wall/fence around the layout).

Even though it is tiny, toy-like, and very modest compared to those shown above in this thread, large, modern Lionel (and MTH) engines look right at home on the scale-like Super O track.

Dennis, I mentioned in my earlier post that I remembered seeing somewhere that Lionel had done some test shots with the tooling around 1999/2000. I found this link that shows a sample of a half curve that was sold on eBay. So, it's interesting to know that Lionel did seem to still have the molds/tooling in Mount Clemens prior to moving to China...…..Hmmm...…….

Rob

https://www.worthpoint.com/wor...adbed-test-459710591

Dennis GS-4 N & W No. 611 posted:Does anyone know, in general terms, what tooling was likely required to manufacture the original Super "O"?

No idea. But the tie beds are molded. Then each piece of trach has 3 identical tie clips stamped and folded metal. Then the rail stock is quite impressive and folded and shaped strips of steel. Then the copper track pins... of course the bus clips...

RAK posted:I am really enjoying this thread. My father built a 5 x 9' Super O layout for me for Christmas of 1960. My parents had stockpiled Super O track and switches against the time when we would move and my father and I would expand the layout. That never happened and the brand new Super O switches were stolen before they ever got used.

Over the years, the layout got damaged and was the target of a robbery (all of the accessories were stolen).

Last year I restored the layout and enlarged it to 5 x 13' (the largest practical size I could have in the available space). It did not even occur to me to use anything other than Super O track (I wanted to make it as it might have been if my father-now deceased-and I had expanded it together back in the 1960's.

The track diameter includes 036 (stock), 042, 048, and 054 (the largest that would fit and allow clearance between the overhang of the locomotives and the small wall/fence around the layout).

Even though it is tiny, toy-like, and very modest compared to those shown above in this thread, large, modern Lionel (and MTH) engines look right at home on the scale-like Super O track.

Awesome layout

Thank you sir!

RAK posted:I am really enjoying this thread. My father built a 5 x 9' Super O layout for me for Christmas of 1960... Last year I restored the layout and enlarged it to 5 x 13'...Even though it is tiny, toy-like, and very modest...

RAK,

I absolutely love the layout! Toy-like layouts are easily among my favorite layouts because I enjoy the postwar style, with a painted table-top, postwar accessories, postwar style buildings, cars, etc. And, Super "O" is hands-down my favorite. Interestingly, I especially enjoyed the Lionel pickle vat car, since my original trains had one. It was one of those cars that always seemed to be on the train table because of its uniqueness for any consist.

"My father [and I] built a 5 x 9' Super O layout [during the] Christmas [week] of 1960." How about that for symmetry? I received the set on Christmas morning, 1960, and by New Years Day, we had a layout constructed. I helped my dad more as an assistant for the benchwork construction, but helped significantly with the painting, track layout, and wiring, which was fairly basic. It was an enjoyable and memorable time.

About 15 years ago, I joined a very nice HO group in our area which is working on a beautiful, highly detailed, 2400 sq. ft., HO layout. That was fun, but my heart belongs to toy train "O" gauge layouts which is what I have. Not that I don't also enjoy visiting "Hi-Rail", or, "Scale-Rail" layouts, since they are beautiful.

robmcc posted:Dennis, I mentioned in my earlier post that I remembered seeing somewhere that Lionel had done some test shots with the tooling around 1999/2000. I found this link that shows a sample of a half curve that was sold on eBay. So, it's interesting to know that Lionel did seem to still have the molds/tooling in Mount Clemens prior to moving to China...…..Hmmm...…….

Rob

Rob,

Very interesting, as is the link. This portion especially caught my eye:

"...what is clear is that this piece was produced using the original tooling that last produced Super O in the mid-1960's. It even still has the original Lionel Corporation/Patent Pending notations!"

I wonder where the tooling is.

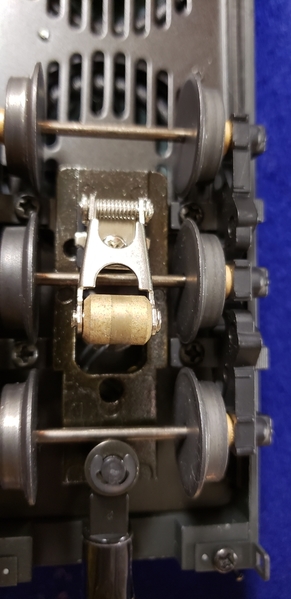

Ok... this section will focus on ROLLER DISTRUCTION on Super O track! Oh The Horrer...

These are photos from my highest milage engines that have only operated on SUPER O. These ran extensively for YEARS on my super o layout, many times they ran continuously for 8hrs straight on my layout during parties.

First up... simply SHREDDED rollers on my Lionel Scale Y3 2-8-8-2 tmcc which would pull my pennsy train for months... and subjected to dieseldan's continuous running... HOURS AND HOURS. This engine must have atleast 200 hours on super o...

Next up... rollers literally FALLING OFF my JLC big boy... this also was always on my layout and has more than a hundred of hours run time.

Before you say it... that black line is rail grime that is pushed to the farthest point in operation (engine running mostly in one direction), and it wipes off...

Finally, the kicker... my Legacy FLAG UNIT sd70ace from about 2008... this engine stayed on the layout for years pulling my UP bathtub gon train and modern freight train. It is the highest milage engine i have. Still runs great except for the DESTROYED rollers.

Again grime is that black line pushed to the far edge of rail contact because engine is mostly turning one direction around layout, this wipes off. You can see the miles on those rubber tires.

So freiends, i dont doubt for a minute people have had worn rollers before, i have seen them on used equipment myself. But i think its more when there is arcing and sparking due to dirty track that causes it.

In each case these are original rollers that came on these engines and i got them NEW and they only have ever run on my super o layout.

I have never replaced a roller yet. I keep my track clean. These engines have only operated at MAXIMUM voltage 18v in legacy and tmcc.... Ripley's...

Attachments

Dennis GS-4 N & W No.About 15 years ago, I joined a very nice HO group in our area which is working on a beautiful, highly detailed, 2400 sq. ft., HO layout.

HO is for wimps Dennis... Glad you came back!

My only rebel moment was that Actually I LOVE N-scale! I always loved it as a kid. In the 90s i got a ton of n scale, and started building layout. Then i went to train shows to get more N, and i would see my old postwar favorites on tables, and kept explaining to my wife how the accessories worked, or stories of how i have a mint one of those back home at my parents house...

Then i went home and filled my car with postwar and drove back to St Louis where i lived at the time. It took only a few weeks to drop that N scale for my good old O scale... i sold it all to some guy and bought a lionel F3AA Western Pacific... the rest is history...

"Its O gauge or NO gauge".

Bob, I actually still had my 3-rail toy layout during my HO tenure. My plan was to learn landscaping with many seasoned layout building veterans, and turn my toy layout into a Hi-Rail layout. (The club actually has a separate room with woodworking tools, and one filled with shelves and drawers and cabinets brimming with landscaping supplies - a layout builders heaven!) After spending hours working on a detailed mountain scene, among other scenery endeavors, I decided that my true interest was running trains, blowing the whistle, smoking up the train room, and watching the trains on the lighted layout. To me, by contrast, the club members' "real" hobby was layout building, and, that wasn't my favorite activity. That finally settled it for me: I wanted to have toy-like layouts where I could watch the trains run.

I was unaware of the term "Cowboy Running" that you used above, but, I'm buying a cowboy hat to augment my U.P. Steam Power hats when I run the trains...

That's why I enjoy the literally lifelike video of RAK's layout in the post above. "O Gauge trains and accessories, vibrant colors, and Super "O" in a beautiful, well designed, postwar style layout.

Dennis... ok i get it you were a spy... well good to have you back...

Super O Bob posted:So freiends, i dont doubt for a minute people have had worn rollers before, i have seen them on used equipment myself. But i think its more when there is arcing and sparking due to dirty track that causes it.

By your own admission, you've gone to great lengths to make your track as smooth and clean as possible. This includes bending the middle rail, squeezing the bus connectors, and smoothing the top of the rails. I'd bet the majority of O Gauge railroaders DON'T do that. I don't believe my dad ever did the first and third of those. Heck one guy in this thread claimed he hadn't cleaned his track in ages. I do remember seeing some tracks have slightly higher or lower middle rails/blades. Slight imperfections in both the bus connectors and middle rails/blades all contribute to additional wear. One can buy brand new traditional track, connect it, and there will be a clickety-clack sound. Guess what? At a microscopic level, each clickety-clack sound is the result of both the wheels and the rollers being worn away. The bus connectors double that clickety-clack. Sure the middle rail may be a softer metal, but try this: punch through a piece of hardwood. Your skin is much softer than the wood, but you'll be able to break it. Some people punch through bricks and other hard materials. However the only people I've ever heard of who had their rollers worn are those who've used Super "O" track. Perhaps it is the imperfections in each track, bus connector, and dirt combined that create arcing and additional wear compared to what happens with conventional track. Whatever the reasons, a number of people have noticed an increased amount of wear of rollers while using Super "O" track. I've yet to learn of anybody who has claimed "O" and/or "O27" and/or FasTrack gauge track has worn out any of their rollers. Why is that? Are non-Super "O" users immune to increased roller wear? Are all non-Super"O" people very meticulous about smoothing their rails, cleaning them often, and eliminating all forms of arcing?

By your username, it's clear you have a great amount of appreciation for Super "O" track. That's fine. I don't want to get you to hate it in any kind of way. Just don't view any criticism of Super "O" track as a personal attack. I've always liked it's look. The thinner middle rail looks a lot better than tracks made by other manufacturers where the middle rails are the same width as the outer rails. However its obvious to me it's not perfect. Apart from the roller wear, I've seen a number of complaints about the unreliability of the switches. Sure, not all fail. However it's enough that anyone contemplating reissuing them will probably think about redesigning them to increase their reliability.