...Again, I think Super O track looks much more realistic than traditional track, and there doesn't seem to be evidence of excessive wear with it. The stress discussion is academic. I would not let the potential for increased roller wear prevent me from using it. But, if I chose to use it, I would not be surprised to encounter higher roller wear. Replacing pickup rollers is not difficult.

MELGAR

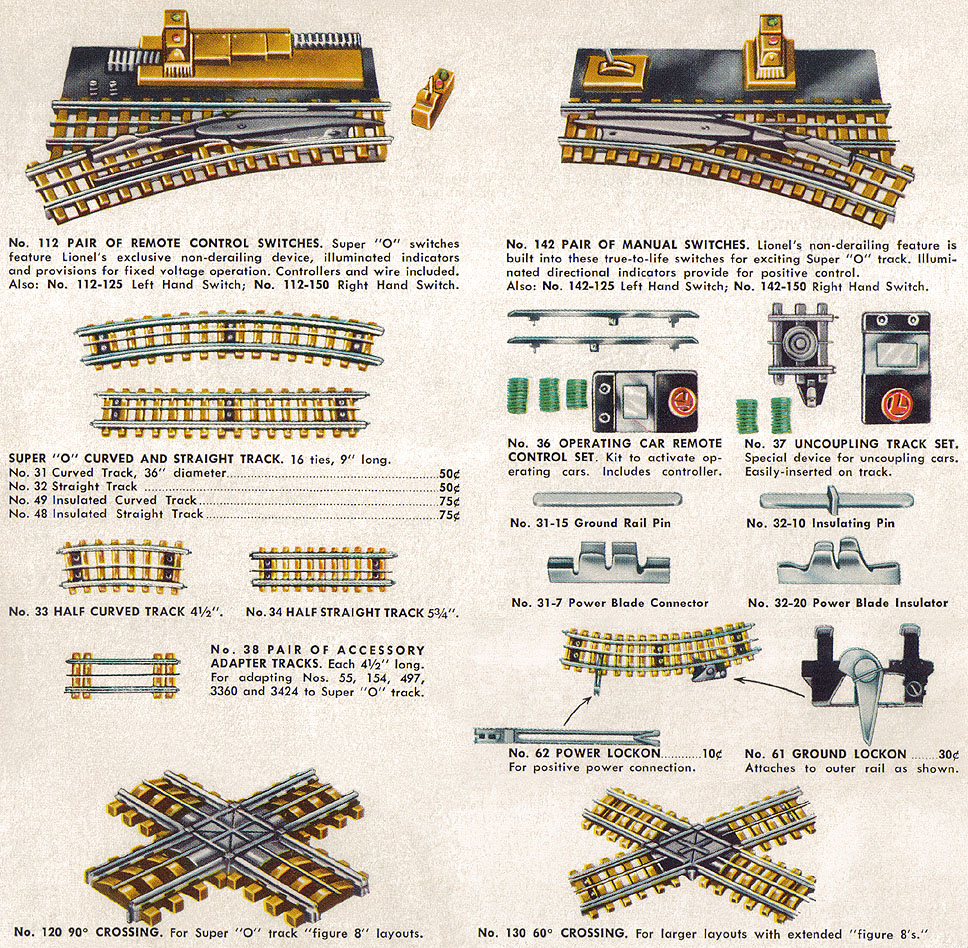

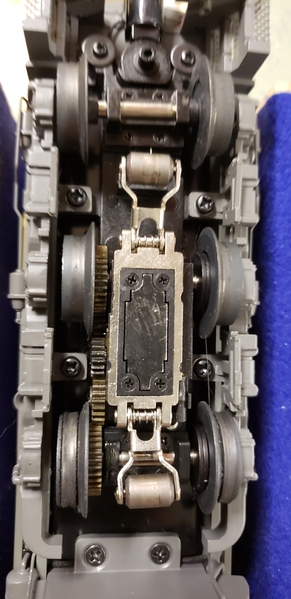

It's been a while since I took my college physics classes (Pluto was still a planet...), but each of you make many excellent points. As stated earlier, I have some roller wear on my postwar 2332 GG-1 from extensive running on my Super "O" layout as a boy, and I simply don't worry about it, and haven't replaced the rollers to date. I have an 18' X 8' layout built with a current manufacturer's track, and without running a number of feeder wires, had significant voltage drop. I never had the same problem with my childhood Super "O" layout which had two mainlines on two, 5 x 9 tables. Each mainline had only two wires, each running fewer than about two feet from the transformer table, with a significant amount of distant track to electrify.

Most of the industrial designers/engineers that I have had the pleasure of working with frequently explained to me that the design of a particular product under discussion often required evaluating different trade-offs in terms of ultimate performance characteristics. Changes in material selection, composition, dimension, shape, etc., frequently resulted in either modest or significant changes in ultimate performance and durability. To the extent possible, these design parameters are compared and evaluated, and a final choice as to design and materials is implemented based on overarching goals, comparative performance and durability, comparative utility, and, of course, comparative pricing. Compare "O" track to Super "O" track, and you can immediately identify the numerous design choices that Lionel evaluated, including, importantly, the size, shape, material choice, and composition of the critical center rail. Based on my experience, observations, and preference, Melgar succinctly crystalizes my view of Super "O", and, the issue of roller wear in the conclusion to his above post, and echoes what many hobbyists have said so far at various points in this excellent discussion.

Knowing my own performance as a child, and my failure to always keep my track clean, I would think a manufacturer would have to expect that at least some of its customer base won't constantly be vigilant with their track cleaning, while others will be more careful. And, some hobbyists have experienced some roller wear, although as Balshis states, not merely on Super "O", but also Lionel 0-27, based on his own lengthy experience.

For me, Lionel fully satisfied its overarching goal of creating a premium track system in 3-Rail that looks very realistic and is a close approximation to real world track. For me, Super "O" also had excellent electrical conductivity. In the design trade-off issue, my strong preference would be for Super "O" even if it causes more roller wear. As Melgar states:

"Replacing pickup rollers is not difficult."

Finally, unless I have forgotten, I haven't seen a post as of yet indicating that anyone has actually changed pick-up rollers because of roller wear, although conceding or stressing its existence.

Quoting Melgar, and fully supporting his observation and conclusion:

"...Again, I think Super O track looks much more realistic than traditional track, and there doesn't seem to be evidence of excessive wear with it."