be very careful with this cleaner as it is extremely flammable. I had it on my brush roller track cleaner and one spark had it immediately on file and needed a fire extingushier to put it out. I do not use it any more on the track.

Replies sorted oldest to newest

Are you referring to the red can that says " Danger: Extremely flammable" in bold type on the front of the can?

or is the green can that is not supposed to be flammable not living up to the marketing?

If this is "Electramotive", it is flammable, and in addition, it is very unfriendly to plastic and paint. Be forewarned.

Mine is CRC QD Electronic Cleaner. It says its plastic safe but extremely flammable.

Just used a little of it on my 022 switches, which now fully close when switch is thrown. Seems to do the trick. Very important to use it sparingly and in well ventilated area. If possible, best to use it outside of the house.

CRC...![]() @ 25 -30 yrs ago I had a pinball machine the solenoid was sticking for the bell so using my right hand in the machine by the coin mech. and my left hand putting the ball down the hole..

@ 25 -30 yrs ago I had a pinball machine the solenoid was sticking for the bell so using my right hand in the machine by the coin mech. and my left hand putting the ball down the hole..

I kept spraying till the ding sounded better! ......that is until IT MADE ONE LOUD BANG and WHOLE bottom of the machine

blew off !! but the good news is the machine and the bell worked fine after that! lol lol

me never used the stuff again... I learned take the part off and clean it by its self NO electrical power till DRY...!

Given the above comments, is there any safe place to use it? Why is it sold at all?

Mark

How much are you using?

Having used this on one huge public display, I would spray it on the rag, and wipe until the fresh spot on the rag wiped clean. If you are soaking your rag or worse, spraying it directly on your track you may just find out it is flammable.

Because it does an excellent job of cleaning electrical contact surfaces, especially in tight places where you might not be able to physically or mechanically be able to reach in order to clean them.

Of course, this assumes that the user reads the directions and warning labels about how and when to use the product which, in this day and age, is probably not a great assumption.

Ironlake2, thanks for the heads up to those that use this kind of stuff. Thank goodness you, your family and house are OK. That was a close call.

We have no idea what type of CRC the OP used. He posted this 6 years ago. He hasn't visited the forum in 2 years. If you're going to post experiences with CRC, please tell us exactly which type of CRC you used. CRC makes dozens of different cleaners.

Like Arnold, I use the QD cleaner. It works great. It is marked flammable so I take the appropriate precautions. Some folks here (Alan Arnold, I believe) like using this type CRC but I haven't tried it yet.

This again...![]()

I've been using it for years with no ill effects. As have many here (yes, I recall Alan's comments) based on the number of threads that are constantly popping up on track cleaning.

As suggested, I use it sparingly for track cleaning with excellent results.

In a bygone era, when automobile engines had distributors, I needed to keep a can in the trunk of my Rambler. Sometimes on stormy days, the engine wouldn't start. I'd pop the distributor cap off, spray in some CRC-556, and away we would go. That product somehow wicked moisture out of the way to prevent interfering with electrical conduction. I just had to throw that can away a year or so ago. I used it on finicky E-units and switch machines (among other things). Best advice: use sparingly.

+1 for their QD electronics cleaner, as mentioned by Arnold. The transformation of an old dirty O22's solenoid plunger's movement from gritty and wooden, to crisp and smooth from a good spray soaking, never ceases to amaze me.

Admittedly, I'm easily entertained.

Tom

I didn’t even notice I was reading a five year old post. It happens all the time. Move the date to the top where it belongs.

Consensus seems to be CRC QD Cleaner is good because it works very well on things like O22 switches, it does not damage plastics, and, most important, use it in well ventillated area and use it sparingly so we don't blow up the house.

What is best way to use it sparingly?

Can we spray a little on a tooth brush outside of house, bring the toothbrush into the basement (where the furnace is), and apply the CRC with the toothbrush on the switch track?

What do you think?

@galley_proof posted:In a bygone era, when automobile engines had distributors, I needed to keep a can in the trunk of my Rambler. Sometimes on stormy days, the engine wouldn't start. I'd pop the distributor cap off, spray in some CRC-556, and away we would go. That product somehow wicked moisture out of the way to prevent interfering with electrical conduction. I just had to throw that can away a year or so ago. I used it on finicky E-units and switch machines (among other things). Best advice: use sparingly.

I also used it on the distributor cap of my Rambler.

Attachments

Reactivating a five year old post on solvents brings up another discussion point. As a California resident I am too familiar with the impact of new regulations implemented in the last five years that impact what is on store shelves. One of three things have happened to these solvents. Some were compliant, like denatured alcohol, so they are sold unchanged. Many were not compliant and the manufacturer, or US distributor, decided to not sell them in California. That has happened to a lot of brands. Some products were non compliant but reformulated to comply and are still sold but the can contents are different. These reformulated products are usually then sold nationwide, not just in California.

We need to be careful relying on 5 year old tests or product descriptions, there is a reasonable chance that the formulations sold today are different. It is best to get the current data from the manufacturers website if it is not all on the can label. These new requirement have impacted availability of even some mundane products like deoderants and house paint. Automotive Carbon Ceramic brakes are impacted by new copper limitations, so 2021 Camaro ZL-1's cannot be sold in California. There is one certain impact, the prices of what is on the store shelves go up.

I have been using CRC's QD solvent/cleaner for at least fifteen years (probably a lot longer) and have never had a problem with it. I've used it when servicing all my engines, both post-war and modern era. It is especially useful on balky E-units where the plunger sticks. It also works extremely well when cleaning out the gunk in brush tubes and gear boxes and on 022 switches. I usually use Q tips immersed in the stuff for those purposes. On occasion I have even used it as a track cleaner on a really grimy section of track. I just spray it on a clean rag and then use elbow grease to complete the work. I always let an hour or so elapse before running trains even though I'm positive it has completely evaporated long before that hour is up. All of this work has been performed in my basement. It really is a superb solvent and if used with just a wee bit of common sense will not blow your house up.

As far as the cautionary statements about it being extremely flammable it should also be remembered that all alcohol products, 70% isopropyl, 91% isopropyl and denatured alcohol are also very flammable and all are used by many members of this forum to clean track in their basements, attics and garages. Like I said, it just takes a little common sense.

Another vote for CRC's QD solvent/cleaner... an excellent contact cleaner for cars, computers and trains ...I've used it forever.

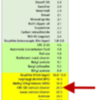

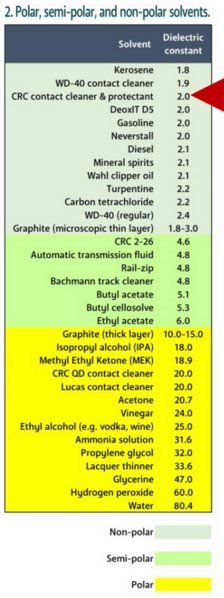

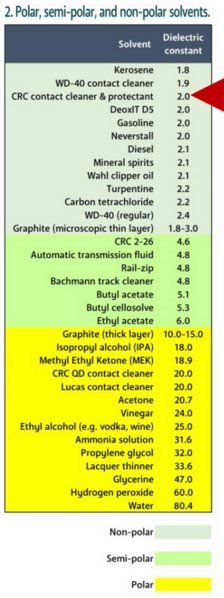

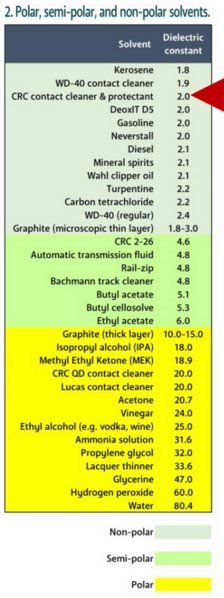

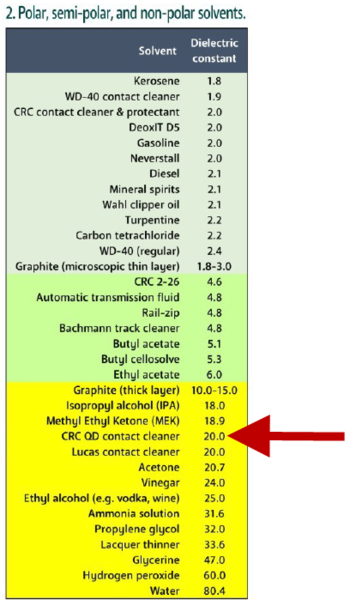

I'm using this stuff right now for cleaning track, but only when it's powered off. I picked it based on a number of threads on polar and non-polar solvents, chart included, it comes in pretty high on the "good" side.

I used to use Isopropyl alcohol, I want to see if this stuff does a better job. I spray it on a rag and then wipe the track with it.

It is very flammable, at least according to the label. I'm thinking in the future for track that I can't reach I can use my track cleaning car and my battery powered Camelback locomotive, no track voltage should mean no sparks to light this stuff up, news at 11:00PM. ![]()

Attachments

Anyone know what the difference between the blue can and red can is?

I know according to the polar attributes from the chart above that neither of those are as desirable as the CRC Contact Cleaner & Protectant that comes in the green can, at least for track cleaning. ![]()

Attachments

@barrister.2u posted:Given the above comments, is there any safe place to use it? Why is it sold at all?

Mark

Even on the can, it says to use in a well-vented area, That it is flammable.

I use it to clean E-Units outside. It does a good job when used properly.

Well, I guess they shouldn't sell rubbing alcohol either then as it is flammable. There are lots of items sold that are flammable, but you need to use them with care and common sense.

@Captain John posted:

I use that for cleaning all the grease out of motors and power trucks, but I don't think I'd use it for track. Looking at the SDS for this stuff, it's pretty nasty, it's 80-100% tetrachloroethylene. Check the SDS for that chemical and I'm not sure I want it in regular use around my layout. ![]()

I’m aware of that John. It is being used taking safe procedures.

When using anything flammable around on trains Common Sense should just Prevail. It's kind of funny 50 or 60 years ago the owner's manual of your new car told you how to adjust the valves today it tells you not to drink the battery fluid.

"Because it does an excellent job of cleaning electrical contact surfaces, especially in tight places"

Yes. Great for that as is Deoxit D5. For track though why would you need such powerful agents?

It seems the biggest electrical problem is where track sections JOIN.

Thank goodness I'm only running "toy trains" on my layout.

I'd hate to have to use / smell these heavy duty industrial cleaners.

Brakleen?? We had a mechanic get carried away with that stuff and everyone in the shop started coughing and had to walk outside.

I'm OK with my lousy 91% isopropyl. The track can only get as clean as its gonna get.

No cleaner is going to stop the electrolysis which is the main reason for dirty track anyway.

What track cleaning fluid can you use in a track cleaning car that won't catch fire ? My insurance company will be real happy if i burn my train building down.

"Brakleen?? We had a mechanic get carried away with that stuff and everyone in the shop started coughing and had to walk outside."

Yes. Brakleen, Gumout Carburetor Cleaner, Throttle Body Cleaner. Bad to breathe. Really bad. Ask me how I know.

Not to mention the ORIGINAL Goo Gone

John

@Craftech posted:"Brakleen?? We had a mechanic get carried away with that stuff and everyone in the shop started coughing and had to walk outside."

Yes. Brakleen, Gumout Carburetor Cleaner, Throttle Body Cleaner. Bad to breathe. Really bad. Ask me how I know.

John

What...... no love for Hogwash? ![]()

@RickO posted:What...... no love for Hogwash?

No only alcohol............................... (91% isopropyl)

@RickO posted:I'm OK with my lousy 91% isopropyl. The track can only get as clean as its gonna get.No cleaner is going to stop the electrolysis which is the main reason for dirty track anyway.

Actually, it's been pretty well demonstrated that the characteristics of Isopropyl Alcohol are low on the list for keeping track clean for any extended period of time. Obviously, you don't have to believe this, and I used Isopropyl Alcohol for years until I saw the light. ![]() Consider picking one of the non-polar cleaners for longer intervals between track cleaning.

Consider picking one of the non-polar cleaners for longer intervals between track cleaning.

I don't recommend gasoline, that would be somewhat dangerous. ![]()

Kerosene? Interesting. I can deal with the smell of that strange as it may sound.

@Craftech posted:Kerosene? Interesting. I can deal with the smell of that strange as it may sound.

Really? I use to deliver that fuel oil and Gasoline and can honestly say that the smell sticks with you. But then again I could give Jimmy Durante a run for the money on nose size. Sometimes I dream of renting mine out for a ski jump.

What about denatured alcohol? I don't see that on the list.

@John H posted:What about denatured alcohol? I don't see that on the list.

I was wondering about that myself as MTH recommends it for cleaning track and wheels.

Denatured alcohol does not bother traction tires.

@John H posted:What about denatured alcohol? I don't see that on the list.

Ethanol (denatured alcohol) has a dielectric constant of 24, higher than Isopropyl Alcohol. In the great list of recommended track cleaners, it's not recommended. ![]()

Denatured alcohol is NOT a non-polar solvent or: Marc learns more chemistry

Will some of the non-polar solvents have an adverse affect on traction tires and various plastics?

IE WD-40, whale clipper oil

@gunrunnerjohn posted:Ethanol (denatured alcohol) has a dielectric constant of 24, higher than Isopropyl Alcohol. In the great list of recommended track cleaners, it's not recommended.

Denatured alcohol is NOT a non-polar solvent or: Marc learns more chemistry

Thanks John. I wonder why MTH says to use it ?

I used 91% alcohol for years, but when I saw the article in MRH and the list of dielectric constants, I switched to mineral spirits. Cleans faster, stuff stays clean longer, easy to use, available at any hardware store.

@feet posted:Thanks John. I wonder why MTH says to use it ?

This wouldn't be the first time you got bad advice from a train manufacturer, right? ![]()

@gunrunnerjohn posted:This wouldn't be the first time you got bad advice from a train manufacturer, right?

Nope and probably won't be the last.

Doesn't the CRC leave an oily film since it is a "conditioner" as well?

@BradFish1 posted:Doesn't the CRC leave an oily film since it is a "conditioner" as well?

That is my impression. The one, and ONLY, time I tried it on the layout it didn't take long for the DCS signal strength do drop dramatically! I then re-cleaned all the main line trackage with acrylic lacquer thinner, and everything returned to normal. Never used it on the layout again.

However it does seem to work pretty well on the electrical plug/connections for the outside heated birdbaths in the winter months.

The CRC cleaner I use doesn't leave anything I can detect on the tracks, and it has zero effect on any track signal that I can see either. It's also rated very good as a non-polar cleaner. Lacquer thinner, OTOH, is a very polar cleaner.

This is the one I have (never used it on track though). It is the one mentioned by Arnold and a few others. It is rated at 20

John

That one isn't really suitable for track cleaning if you want the cleaning job to last.

@gunrunnerjohn posted:The CRC cleaner I use doesn't leave anything I can detect on the tracks, and it has zero effect on any track signal that I can see either. It's also rated very good as a non-polar cleaner. Lacquer thinner, OTOH, is a very polar cleaner.

@gunrunnerjohn posted:The CRC cleaner I use doesn't leave anything I can detect on the tracks, and it has zero effect on any track signal that I can see either. It's also rated very good as a non-polar cleaner. Lacquer thinner, OTOH, is a very polar cleaner.

Must admit that I don't know what a "no-polar" and "polar" cleaner is, but both acrylic lacquer thinner and denatured alcohol work excellently on my Atlas solid nickel silver track, for some 10 years, without any issues (we had both MTH and Legacy/TMCC control systems operating simultaneously).

@gunrunnerjohn posted:The CRC cleaner I use doesn't leave anything I can detect on the tracks, and it has zero effect on any track signal that I can see either. It's also rated very good as a non-polar cleaner. Lacquer thinner, OTOH, is a very polar cleaner.

How do you apply it? Directly as a spray? Or onto a cloth to wipe the track?

I spray it on a cloth and then wipe the track with it. Too messy spraying it directly.

Thank you GunrunnerJohn. This is great information. Been using the red can for years with poor results. ![]()

I used Isopropyl Alcohol for years, and it usually needed to be used again very quickly. So far, the CRC in the green can has worked much better, so there may be something to the polar/non-polar solvent issue. ![]()

Just cleaned my temporary layout in the kitchen/dining room with kerosene. The wife went ballistic.

I tried to explain that it was the top rated non-polar solvent and she wouldn't listen.

Sheesh ! ![]()

Worked GREAT though.

John

@gunrunnerjohn posted:I used Isopropyl Alcohol for years, and it usually needed to be used again very quickly. So far, the CRC in the green can has worked much better, so there may be something to the polar/non-polar solvent issue.

I have been using denatured alcohol forever (beginning in N scale in the 1980s), but I’m going to give this CRC cleaner a try.

@Craftech posted:Just cleaned my temporary layout in the kitchen/dining room with kerosene. The wife went ballistic.

I tried to explain that it was the top rated non-polar solvent and she wouldn't listen.

Sheesh !

Worked GREAT though.

John

Rule of thumb. Avoid using products designed as a fuel for any other routine purpose.

You could always try carbon tetrachloride, some seriously nasty stuff! ![]()

@Jim R. posted:Rule of thumb. Avoid using products designed as a fuel for any other routine purpose.

Unfortunately, many of the specific cleaning products are also very flammable. ![]() I will say, the CRC in the green can smells better than kerosene.

I will say, the CRC in the green can smells better than kerosene. ![]()

@gunrunnerjohn posted:Unfortunately, many of the specific cleaning products are also very flammable.

I will say, the CRC in the green can smells better than kerosene.

And that is what I'm afraid of, fire. I am leery of using anything flammable in a track cleaning car.

I don't put the cleaner in a track cleaning car. The only way I'd do that is using my battery powered Camelback, that won't have any sparks to the track if I kill the track power.

I don’t know how it falls in the polar/non-polar cleaner but at the club we’ve started using this rubber cleaner and rejuvenator that’s works pretty good.

@Arnold D. Cribari posted:Consensus seems to be CRC QD Cleaner is good because it works very well on things like O22 switches, it does not damage plastics, and, most important, use it in well ventillated area and use it sparingly so we don't blow up the house.

What is best way to use it sparingly?

Can we spray a little on a tooth brush outside of house, bring the toothbrush into the basement (where the furnace is), and apply the CRC with the toothbrush on the switch track?

What do you think?

Fumes can go a long way.

Also, some furnaces draw combustion air from outdoors. If spraying outdoors, don't do it near the intake. At least I don't need to say "don't ask how I know this", because I didn't learn it the hard way.

The number of unknown hazards with these products is astounding. I had never thought about the possibility of sparking a fire as a result of cleaning the track. Thanks for the heads-up.

@Arnold D. Cribari posted:Consensus seems to be CRC QD Cleaner is good because it works very well on things like O22 switches, it does not damage plastics, and, most important, use it in well ventillated area and use it sparingly so we don't blow up the house.

I don't know where that "consensus" came from, but leave me out of that group. The CRC QC ranks very low in the list of effective and long lasting track cleaning products.

Here's the Product Description for the CRC Contact Cleaner & Protectant, looks like they think it's safe for most plastics as well.

Attachments

@Mallard4468 posted:Fumes can go a long way.

Also, some furnaces draw combustion air from outdoors. If spraying outdoors, don't do it near the intake. At least I don't need to say "don't ask how I know this", because I didn't learn it the hard way.

The number of unknown hazards with these products is astounding. I had never thought about the possibility of sparking a fire as a result of cleaning the track. Thanks for the heads-up.

Some of these solvents listed are real dangerous. The vapors form some of the solvent discussed will "travel" along a horizontal surface finding an ignition source. An example could be using one of these solvents to clean parts in an open tray, set to the side and uncovered. Now one plugs in a small hand held soldering iron to a nearby outlet. A small arc occurs in the outlet and a resulting flash occurs, followed by the remaining fluid in the dish burring.

Same thing could happen with a rag with enough solvent applied.

Other solvents may be a bit more volatile and not concentrate near the surface and therefore be below the ignition point at some distance. They will smell. Please be careful from both a fire hazard and health hazard.

Obviously, one has to be careful with any flammable solvent.

Just wondering if Lionel ever advised what to clean track with. Other than their tiny bottle in their kit. And if that's all they recommend, does anyone know what it consists of?

@Train Nut posted:Just wondering if Lionel ever advised what to clean crack with.

I think if you’re using crack, volatile combustibles are the least of you worries!

@gunrunnerjohn posted:Obviously, one has to be careful with any flammable solvent.

Right Guard and and a lighter were really dangerous in the locker room back in the 60's.![]()

Whatever happened to the blue colored track cleaning solution . I haven’t seen that in about 10 years . It used to be in several of the hobby stores. I know KLINE used to sell it.

What did that consist of?

@gunrunnerjohn posted:You could always try carbon tetrachloride, some seriously nasty stuff!

Carbon tet is listed as a carcinogen by the government. Was used by the dry cleaning industry for many years, seeps into the soil and is now considered a hazardous waste material. My daughter works for an environmental company and every time she has to take soil samples from an old dry cleaners she finds it.

50 years ago when I was in college, we used carbon tetrachloride as a solvent in running NMRI testing in chemistry lab, no hydrogen atoms to interfere with the chemical.

For most of my needs, Odorless Mineral Spirits rule!

I don't know what it's Polar rating is, but it is cheap, good smelling, instantly dissolves all grease, grime and oil, instantly cleans an oily paint brush, and evaporates amazingly fast. It is flammable, but not explosively so.

It does zero harm to metal that I can tell. It will fade plastic if you apply it directly.

When I need to clean a small electric or metal part, I pour some into the upright cap, drop the part in it, give it 3 minutes, dump the liquid and part out onto a cloth, and I am done. No wiping, scraping or scrubbing. The rag dries out in about 2 minutes from evaporation.

Mannyrock

@Craftech posted:Just cleaned my temporary layout in the kitchen/dining room with kerosene. The wife went ballistic.

I tried to explain that it was the top rated non-polar solvent and she wouldn't listen.

Sheesh !

Worked GREAT though.

John

😂😂😂I can’t stop laughing. Beautiful.

@gunrunnerjohn posted:I'm using this stuff right now for cleaning track, but only when it's powered off. I picked it based on a number of threads on polar and non-polar solvents, chart included, it comes in pretty high on the "good" side.

I used to use Isopropyl alcohol, I want to see if this stuff does a better job. I spray it on a rag and then wipe the track with it.

It is very flammable, at least according to the label. I'm thinking in the future for track that I can't reach I can use my track cleaning car and my battery powered Camelback locomotive, no track voltage should mean no sparks to light this stuff up, news at 11:00PM.

Will this tend to be unfriendly to the rubber of traction tires?

Just about any material has an MSDS sheet. Material Safety Data Sheet. for CRC Contact Cleaner, (7) pages. Click on the underlined phrase. All is predicated, on the fact, that everyone can read, and understand the English language. ![]()

![]()

@Keith L posted:Will this tend to be unfriendly to the rubber of traction tires?

Since it shouldn't leave any residue after it drives (quickly), I can't imagine it being a problem for traction tires.

Anybody use this? ACT-6006. Made by Aero-Car hobby lubricants.

feet, what all do you use it on? any problems or concerns? thank you, dave

@Dave Nichols posted:feet, what all do you use it on? any problems or concerns? thank you, dave

Dave I.ve never used it. I stumbled across it while searching for something suitable for cleaning track.

Keep in mind the chemical is not good for breathing in your lungs read MSDS data Sheet below always use OUTSIDE UP WIND SO YOU DON'T INHALE IT !

Alan Mancus

@Alan Mancus posted:Keep in mind the chemical is not good for breathing in your lungs read MSDS data Sheet below always use OUTSIDE UP WIND SO YOU DON'T INHALE IT

Most of the stuff on the list of recommended track cleaners fits that category Alan, that's not exactly news. Besides, exactly how are you going to carry the layout outside to clean the track? I don't know about yours, but mine is just a bit too large for me to haul outside!

As with model paints, and related materials. An organic respirator.

Compared to the expense on a layout so far, the cost of the respirator, pictured, is peanuts. IMO. Cartridge(s) are replace-able.

I've never had an issue with the CRC cleaner. It even fixed my fussy thumbwheel on my dcs remote! Just don't spray at sparks! Lol

I have used 91% alcohol for track cleaning many years. Recently research has convinced me the mineral spirits is better and recently it was used. But now the track cleaning solvent is immaterial as I do not have to clean my track ever again.

I used NO OX ID A special as a track treatment in January 2022. Train operation on my conventional control, 027 layout with 31 Marx switches is much better and trains can be operated much slower. The track and improved operation has been better for 11 months so far and only time will tell if track cleaning has been eliminated forever.

Charlie

@Choo Choo Charlie posted:I have used 91% alcohol for track cleaning many years. Recently research has convinced me the mineral spirits is better and recently it was used. But now the track cleaning solvent is immaterial as I do not have to clean my track ever again.

I used NO OX ID A special as a track treatment in January 2022. Train operation on my conventional control, 027 layout with 31 Marx switches is much better and trains can be operated much slower. The track and improved operation has been better for 11 months so far and only time will tell if track cleaning has been eliminated forever.

Charlie

But, if you have traction tires on your engines will NO OXID damage them?

Almost any of the cleaners we are talking about have organic compounds in them that are in some way, shape and form toxic. It is why they say use them in well ventilated spaces and yes they are flammable. Compounds like benzene, carbon tet (used in clearning and firefighting systems), toluene, all are carcinogenic if exposed to it for long periods of time. I remember first day of organic chem lab, the TA running it listing the most common reagents we would be using and then saying every one of them was on the list of top cancer causing ingredients....

One thing to be careful of, don't use tuner cleaner (I had someone after I told them not to use it, use it; tuner cleaner has a lubricant in it. it is conductive, but also will attract dirt).

When using any kind of cleaner I recommend wearing disposable gloves (advice of course I don't always take myself), and when using it put a small amount on a lint free rag, wipe, then put more on the rag. It means the chemical goes where you need it only and it helps a bit with the fumes.

Someone suggested to be electronic wipes (like you use to clean monitors and displays and the like), I don't recommend them, most of them are alcohol based (some of the ways they describe alcohol on the ingredients cracks me up, and people tell me "it doesn't have alcohol"..it does.

Feet

I have some engines with traction tires. I did not use these locos to spread the NO OX during installation and they run fine after the NO OX was wiped off. They do not slip as the NO OX is gently wiped off after 24 hours after treatment. There are at least two sides on NO OX and a search on OGR will give both sides. NO OX is the only treatment that has shown to eliminate track cleaning. For me it has been only positive to date.

Charlie

@Choo Choo Charlie posted:Feet

I have some engines with traction tires. I did not use these locos to spread the NO OX during installation and they run fine after the NO OX was wiped off. They do not slip as the NO OX is gently wiped off after 24 hours after treatment. There are at least two sides on NO OX and a search on OGR will give both sides. NO OX is the only treatment that has shown to eliminate track cleaning. For me it has been only positive to date.

Charlie

Thanks Charlie!