I have space in my garage for a 6x10 layout. I'd like to run two freight trains and was planning on using a design similar to the attached diagram (which is 5x9), but adding one or two stub end spurs since I have additional space. (Dumb question that I have not seen answered on forums - when a train enters a spur, does it go forward or backwards?)

Ideally, I want a train table that has four eye bolts sunk through the border and bolted to the bottom for additional support. The eye bolts would be used to attach the surface with wires to a pulley or pulley system so I could raise it to the ceiling and fit my car underneath.

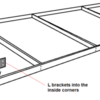

My son-in-law provided a diagram (attached) of how he thought the table top should look (I would add one more crosspiece so that they would be 2' apart. I went to my friendly local lumber yard and was advised I could make the frame out of 1x4's and the surface out of 1/2 inch plywood (they stock 10' long plywood, so that simplifies things and provides additional strength).

So, now I have a LOT of questions to throw out. I would appreciate your comments on any or all of them.

1. Any thoughts on the design? I don't want to make it too complicated, but if you have pictures of other 6x10's, would love to see them.

2. Are 1x4's and 1/2 inch plywood the right materials? I don't think that the total amount of weight on the table will be that much, and 1/2 inch plywood is pretty heavy. On the other hand, it does provide additional support for the pulley system. When I lower it, I would simply have it sit on heavy duty saw horses.

3. And speaking of the pulley system, I am COMPLETELY ignorant on how to accomplish this. I will probably have to hire a handyman to build it. Does anyone out there have this setup? Can you send me a photo or a design?

4. Finally, aesthetics. At our local train store, their Fastrack setup is on a big table with thin green indoor/outdoor carpet as the surface. It looks surprisingly good. I was thinking of using the same idea (there is some really thin/cheap green indoor/outdoor at Home Depot that looks like it would work well), then using a boxcutter to remove the areas that will be roads and filling them in. I am artistically challenged, so keeping things simple appeals to me. Thoughts?

I so appreciate the OGR forum and being able to get advice from people who are light years ahead of me.