![]()

|

|

![]()

I built mine up tonight Gunrunner. Seems to trigger green on some of the larger commands.

Now to try a few different older TIUs and see what happens with those. I've got one here that the track signal only gives about a 6 on the signal test - could be a good candidate to try out.

Thanks Gunrunner.

Jim

Adrain, John

Thanks for taking the time & effort in coming up with this DCS-TIU Port Tester tool. It is a quick and easy way the see if you are getting full DCS signal output from the TUI port. I tried the tool out on several TIUs and it works as intended. I will most likely first use the tool the check out a TIU port and use the scope if needed. TIU ports where I have a 14vpp signal, I have both Red & Green LEDs lit. Ports where I am in the 8-9 Vpp range, only the red LED is lit. <5-6 volt range, neither LED lights.

Thanks again guys,

Bob D

NJ-Hi Railers

GRJ, after sending you an email, I saw above that you are sold out. Where on these 6 pages can I find the final schematic, or could you please post it again?

I'm not going to get involved with producing boards, which I guess is what the other two files you posted with the BOM are for. Any reason I can't just use breadboard and hardwiring, following your top view pictures and the schematic?

RJR posted:GRJ, after sending you an email, I saw above that you are sold out. Where on these 6 pages can I find the final schematic, or could you please post it again?

I'm not going to get involved with producing boards, which I guess is what the other two files you posted with the BOM are for. Any reason I can't just use breadboard and hardwiring, following your top view pictures and the schematic?

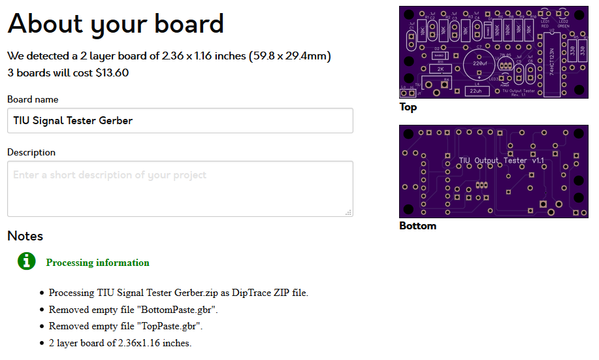

No reason you can't wire it on a perf board. OTOH, depending on how much you think your time is worth, you can have three PCB's for $13.60 from OSH Park. Sell a couple for $4-5 and build the other one up.

Here's the complete design archive, including the Schematic and the top view of the board. Also included are the Gerber files for ordering a board from OSH Park, the BOM for the parts, and the DIPTRACE files.

Thanks, GRJ. Your post gives me a thought: anyone have one of these boards from OSH Park that they want to sell?

RTR mentions boards from SEEED. Are these identical?

GRJ, if that doesn't work, do I merely contact OSH Park by email, attaching your Gerber file, and they can then complete an order?

If you order boards from most anyone using those Gerber files and use the default of 1/16" thickness, you'll get the same board. As far as OSH Park, you simply establish an account there, and drag-n-drop the ZIP file containing the Gerber files on the upload block and follow your nose. Their defaults will give you the board required. SEEED Studio is similar, you just get more boards for your money.

Yes, the boards I ordered are identical to GRJ's. He created the files I used to order from. They are even red as in GRJ's picture above for the ones he ordered. I hope to have everything together by sometime next week, probably late in the week. Email me if you want a kit, email in profile, and I will add you to the list. I think I have 6 or 7 kits left. I only ordered enough boards for 10 kits, but I could order more if there is interest.

I have most of the parts, but I decided to order some terminal blocks to see if they would fit on the board, but the boards were ordered sometime prior to my thoughts here. I really don't expect them to fit? This was an after thought after thinking about one of GRJ's posts above. Probably better to revise board BEFORE trying to adapt terminal block, but thought it might be worth a try anyway...

Also as GRJ says, ordering from OSHPark is really easy too. And GRJ included a parts list with the Digikey part numbers on it already so that part should be pretty easy too. That is also what I used to order parts. I used the defaults GRJ mentions above to order the boards, but selected Red for the board color. I think OSHPark only has purple for colors, not certain on that though?

Should be no reason a .1" spacing connector won't fit in the two pin slot for the TIU connection. It's a standard 2.54mm (.1") spacing, and there's plenty of room around it for most connector styles.

Jim Sandman posted:I built mine up tonight Gunrunner. Seems to trigger green on some of the larger commands.

rad400 posted:...TIU ports where I have a 14vpp signal, I have both Red & Green LEDs lit. Ports where I am in the 8-9 Vpp range, only the red LED is lit. <5-6 volt range, neither LED lights.

Has someone posted instructions on how to calibrate a home-built unit - particularly without an oscilloscope? From scope photos earlier in the thread, measuring peak-to-peak amplitude of the funky-looking DCS-signal can introduce a calibration "error" of, say, 1-2 Volts.

As a simple Go/No-Go or Go/Maybe/No-Go tool perhaps this is not an issue and the instructions can be as simple as to set the trimpot to the mid-point angle (or whatever). Just asking. ![]()

Well, I started with a known good TIU, which I suppose can be a challenge for someone without a 'scope. I set the unit to trigger red and green on that signal. Then I used a cap across the TIU output to step on the signal until it was only around 8 volts and made sure that only the red light lit.

rtr12 posted:...I have most of the parts, but I decided to order some terminal blocks to see if they would fit on the board, but the boards were ordered sometime prior to my thoughts here. I really don't expect them to fit? This was an after thought after thinking about one of GRJ's posts above. Probably better to revise board BEFORE trying to adapt terminal block, but thought it might be worth a try anyway...

If by terminal block you mean the screw-terminal style like JOHNF showed in his hand-built unit, note that you can get 0.1" style for about a dime a piece on eBay. Note that on eBay listings, "2.54mm" is the operative search term (vs. 0.1"). If anything, looks like the trimpot might be a tad close in the left-to-right dimension?

GRJ and Stan,

That is what I ordered, 2.54mm (0.1"). I looked at GRJ's drawings and info in the files posted. I just ordered a few from Digikey to see if they would work. They were not all the expensive, though ebay would be cheaper as Stan's picture shows. Nice to hear that you think there will be room for them. ![]()

Set up instructions for those of us without 'scopes' would be really nice to have too! If there is such a way?

Stan, GRJ,

Could this earlier post below from Ardian be a clue to calibration?

Adrian! posted:Dave45681 posted:Thanks for posting this!

So to set the trim pot, do we set it up on a TIU output we have reason to believe is good and just adjust the pot until the LED starts blinking? Or is there a better method during construction (maybe applying a DC signal directly to the B/C node of the circuit before installing the filters on the front end?)?

Thanks for all the good discussions you have been posting on the topic.

-Dave

Hey!

Yup, the trimpot just sets how many volts of dcs signal you need before the light flashes. If you turn it all the way up it’ll flash at 2.5V. In the middle it would flash at 5V. Near the top maybe 50V or more. I think it’s easiest to just tune it against a good channel like you suggest. Tune it to the point right where it barely flashes on a working channel, then leave it set there as your threshold of good and bad for future tests.

Stan & GRJ,

Another possible clue from Adrian, maybe? He also mentions changing to 10k resistor and 100nf cap in one spot.

Adrian! posted:Here's how mine looks.

After more playing around side-by-side with the scope I suggest a shorter time base so you can see long gaps between packets like the one in the video (10K and 100nF). I don't have a pot handy so I used a 3K and 1K resistor for the divider.

Just thinking this might help some of us in the less knowledgeable category here. I know what he means about the R & C changes, but others may not? I asked Adrian about this earlier in the thread (near this post, I think) and he confirmed what I was thinking here about the RC changes.

In general, the calibration "problem" is the accuracy, quality, etc. of the measurement reference or standard. The idea of using a "known good" TIU output as the reference is no doubt the most practical...but what does "known good" mean?!

As Adrian pointed out elsewhere, you can get 10's using the DCS signal quality test with signal levels of only 3-4 Volts. Yet, if the signal level is only 3-4 Volts, you certainly have a degraded TIU channel and ought to change/upgrade the internal electronics.

Adrian did the heavy-lifting with his original post in this thread and demonstrated the concept with components he had on hand. I think you need to focus on the latest incarnation of the design as that's what you're apparently building and offering to other members.

If you don't have a scope to verify that a "known good" reference signal is indeed 14V peak-to-peak (or whatever), I'm thinking you could use a 12V DC voltage (or even a 9V battery) to serve as a low-cost DC "reference" voltage for the express purpose of getting you in the ballpark (within, say, 20%) which ought to be good enough for a simple tester. The idea would be to inject this DC voltage into the trimpot.

Thanks for the good ideas here, Stan! I am not sure my TIU has a 'known good reference' channel, but the 12vdc I have plenty of, also 9v batteries. I built one board from the original design (OSHPark), but have yet to get any reading from it (hoping it was something I did wrong). Although my layout still runs everything with no problems or DCS errors?

Hopefully I can try this out next week sometime if the new boards arrive by then. The new boards are from GRJ's latest design files and he has assembled and tested one of those already. Really hoping my TIU provides a good reading this time! ![]()

Here's one minimalist approach to "calibration" - no scope, no battery, no other components required! This uses the relatively accurate on-board 5V voltage as a reference.

With the 2 LED method (vs. original 1 LED method), there are 3 "zones". (1) BOTH LEDs blink meaning good signal level, (2) 1 LED blinks meaning marginal/degraded signal, (3) Neither LED blinks meaning very low or no signal.

1. Apply AC track voltage to module. Presumably the "Power" LED turns on. Use DC voltmeter to confirm you have 5.0V DC at the point indicated. The DC- side of the DC measurement is the circuit ground.

2. By momentarily touching +5V to the DC+ point as shown (using, say, an alligator jumper cable), you are effectively applying a 5V trigger. By turning the trimpot fully in one direction, you should be able to make BOTH LEDs flash each time you tap +5V to the DC+ point. By turning the trimpot fully in the other direction, you should not be able to make either LED flash. The idea is to adjust the trimpot to the case where you're at the threshold between NEITHER LED flashing and 1 LED flashing. To be clear, this is a separate threshold than between 1 LED flashing and BOTH LEDs flashing.

This simple (?) procedure "calibrates" the unit to flash both LEDs on a 10V DCS signal. This is probably good enough IMO but to each his own.

3. If you have access to a "known good" TIU channel, it will surely trigger BOTH LEDs as it appears you get more than a 10V DCS signal. You can then further adjust the trimpot with the "known good" TIU knowing that you have AT LEAST a 10V output. To do this, you then send a real DCS signal out the TIU and adjust the trimpot to the point where 1 LED flashes and BOTH LEDs flash.

Interesting approach Stan, and it does have the virtue of being really simple.

Stan,

Thank you for the additional info above! I printed all of it so it will be handy for testing. Maybe I will go back and fiddle with the original board while I am waiting on the newer ones.

Access to this requires an OGR Forum Supporting Membership