This is one of the few times I had something to share on the Forum, and my search revealed the same or similar topic, so I'm reviving this one.

Yesterday, my 7 year old grandaughter and I were each running a freight train pulled by an LC+ loco, each with our own remote unit, on separate main lines. We were having a great time doing that.

Unlike most young children running trains, my grandaughter was very content going nice and slow, occasionally blowing the whistle or ringing the bell. I was doing the same. Neither of us was racing our train. She ran hers flawlessly.

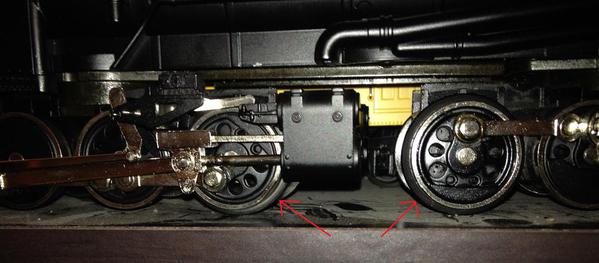

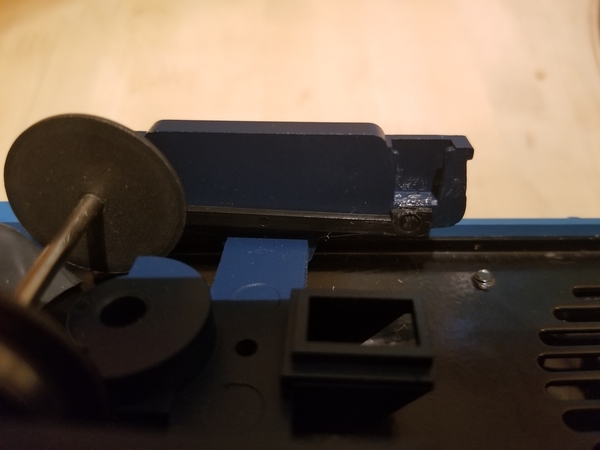

I decided to back up my oil tanker unit train into the siding to the right of the O22 switch on the right side in the photo below, leave the tanker cars in that siding, and have my LC+ Jersey Central Pacific Steamer pick up passenger cars on the other side of my layout.

Notice how close the track is to the edge of the table in the above photo. Also the O22 switch on the right, if thrown straight, leads to the siding where I was trying to park about 7 or 8 tanker cars; if thrown to the left curve, then the train would continue along the reverse loop.

The switch was thrown straight to back the tanker cars into the siding. The cars did not have enough clearance from the back wall, several cars derailed, and one tanker and the locomotive and tender fell off the table striking the concrete floor 4 feet (about 48 inches) below the table.

2 metal ladders were dislodged from one tanker car. I found them on the floor, and inserted them back on the car, so no harm done.

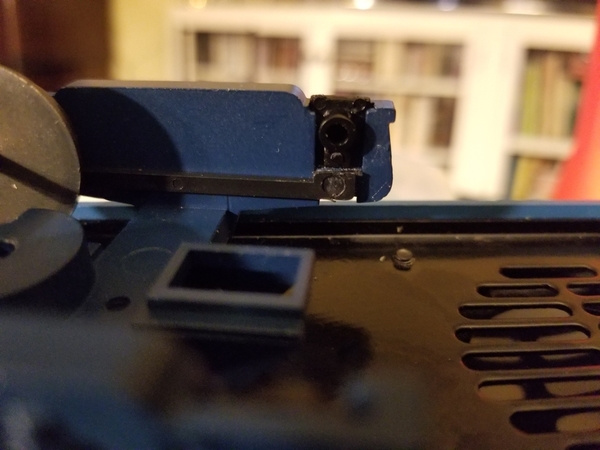

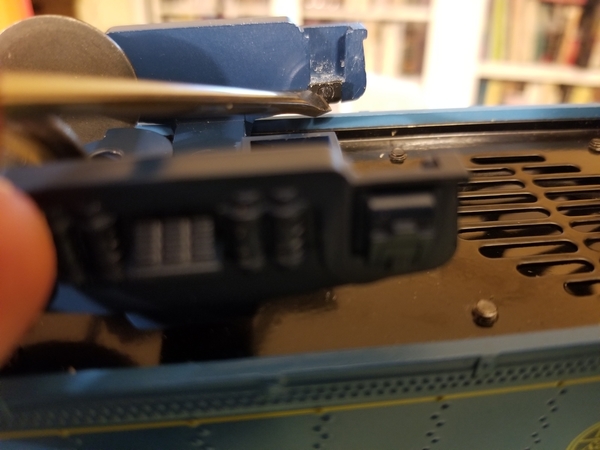

But my heart sunk when I saw one set of wheels on the floor that came off the tender. I examined the tender closely and noticed a small piece of plastic that I believe is supposed to be part of the journal box, had broken off. That broken piece of plastic holds the wheel axle and wheels in place. I frantically searched the floor for that small piece of plastic, and found it after about 10 minutes of searching for it.

I had some left over Loctite Superglue. I put the axle for the loose pair of wheels in each journal box, and put a tiny dab of superglue on the edge of the broken piece of plastic, put the axle and wheels back in the journal box, and pressed the glued broken pieces together.

I now have the tender on the track in another siding in the middle, not the edge, of the layout. I won't touch the tender for at least 24 hours to give the Superglue plenty of time to dry/set.

I have always known that my trains are in danger of falling off the table when running near the edge of the layout where the locomotive derailed and fell. I'm thinking of putting pillows on the floor there when running trains so if they fall off the table, it would be a soft, not hard, landing to minimize/eliminate damage.

What do you think?

Arnold