Yes, it is possible and easy. Many of these basic transformers are out there and are quite affordable. I purchase them in lots with trains. I always service them before selling them off to those in need of basic power with whistle control. The old disc set up that Lionel used is unreliable and frustrating to service if you dare. The new diodes are readily available and inexpensive. They do not fit into all of Lionel's vintage transformers, but the ZW and KW are favorite targets for conversion. The 1033 is also convertible.

You will need a long needle nose pliers, a strong pair of snips, a small blade screw driver and a 7/16 wrench. The diode comes with several different washers and a nut.

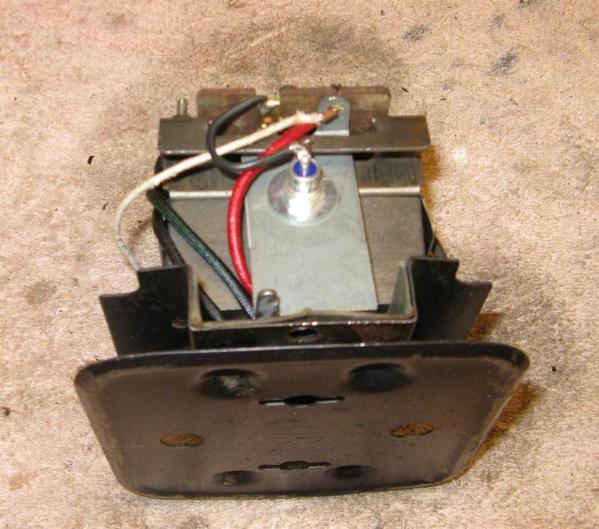

Shown above is a 1033 original set up with the disc and speed nut set up. Simply get the edge of a small flat blade screw driver under one of the teeth holding the nut to the stud and twist, it should come right off. Remove the disc and round insulating washer from the pin.

Next you will have to cut the tab off where the screw driver is pointing. It was connected to the disc stud. Remove the piece and the disc stud and insulator.

You should end up with these removed parts.

Clearance is tight so you will need to bend the disc plate a little. Be sure to use a pliers and hold the fiber top plate and the tab where it connects to the top fiber plate and use your fingers to bend out the bottom of the disc plate.

Carefully bend the tip of the diode as shown above.

Put one of the large washers on the diode, and place it in the mounting plate hole while installing the other large washer and the nut on the inside. Tighten with the wrench while holding the nut with the needle nose pliers. There should be a minimum of 1/8" of clearance between the end of the diode and the core. If the diode is touching, you'll need to bend the mounting plate a little more.

Check your side clearance by looking down from the top. The 1033 has a bakelite case so its OK if the diode touches it slightly. One more step to go.

Take a short piece of 18 gauge wire and solder one end to the Diode tip, and the other end to the remnant of that brass tab you cut off in the earlier step.

That's it! You've just converted a 1033 to Diode whistle control. Replace your power cord if needed then reinstall the cover and handles and your set to go.

Tin