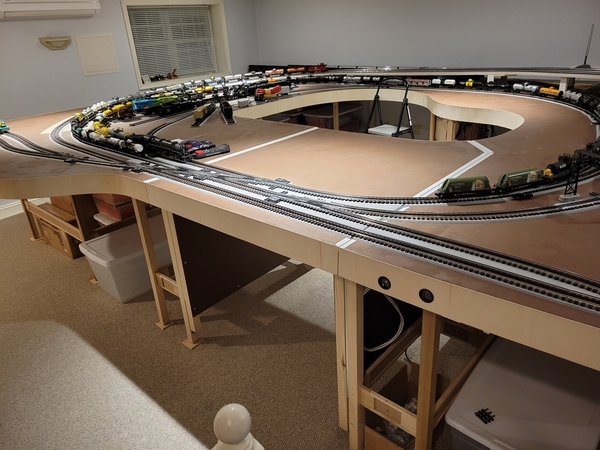

I have found many ways to access a layout by searching here in OGR forums and on the internet. After weighing different parameters and limitations of many of these, and building a few hinged access ways, I decided that the lifting table offers the best means for my situation.

I spent a few weeks sourcing parts and drawing up plans. Due to lumber prices over the first half of the year and a lack of quality I have chosen to build with Arctic Birch plywood. There are 16, 3.625" (3.5 + plus 1/8" for kerf) wide cuts per 5'x5' sheet, and the 18mm (3/4") thickness runs about $70. I don't have to deal with any twisting and warping. The birch ply is prone to splinters so some light sanding is necessary on any sharp corners. Otherwise it is a joy to work with. Many of my shop cabinets are built with this product.

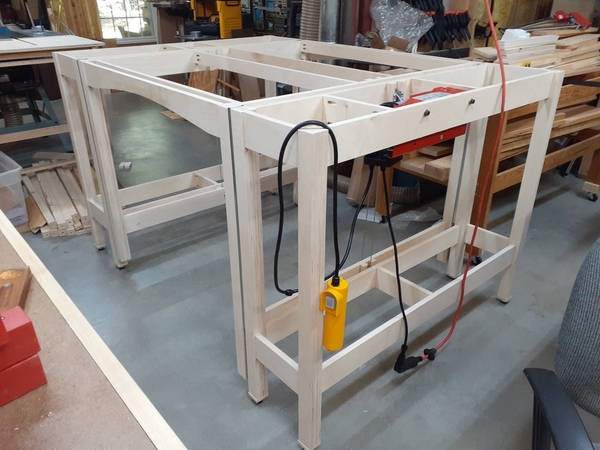

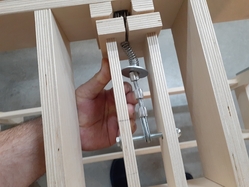

The legs are made from laminated from (2) 18mm and (1) 12mm strips. This results in a dimension real close to 1 7/8". This is also real close to the width of the heavy duty cabinet sliders. All other parts are 18mm plywood. The joints to the legs are mortise and loosely fit tenons, glued with liquid nails. (6/28/2021 edit: don't make the mistake I did, buy the $7 tube of construction adhesive. The $2 is easy to clean up but I'm finding some joints that have come lose, those joints are now pinned with screws through the tenons.)

This is the best approach for me to insure things come out square when I clamp them up. This table is within a 1/16" of being square in all planes. All of the cross bracing is secured with pocket screws, and they will be used on all other benchwork to come. The bracing across the lift section can be removed to allow carrying the two sides independently.

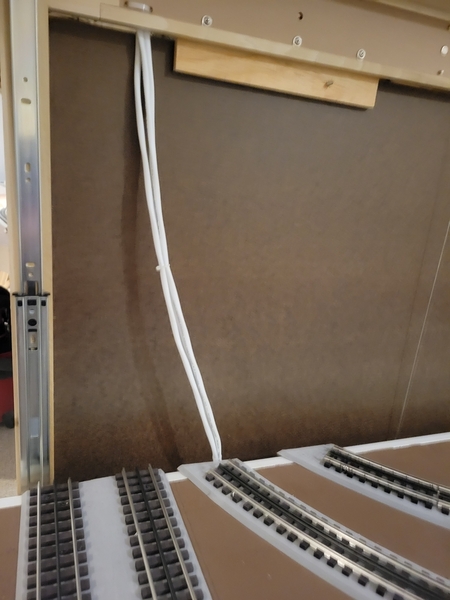

The dimensions are 66 3/4" wide x 48" deep. It stands 39" tall, for a finished height of 40" with plywood and homosote added later. The walk through is 38" wide and, with the arched stretchers, the height is almost 65". The finished side of the basement will not be totally dedicated to Turkey Hollow RR and will not be accessible from two sides so I need to be sure I have plenty of room for whatever may need to pass.

Sorry for the shaky video. I was trying to keep my phone still and control the table at the same time.

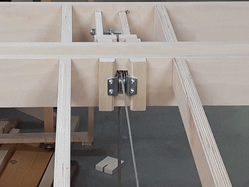

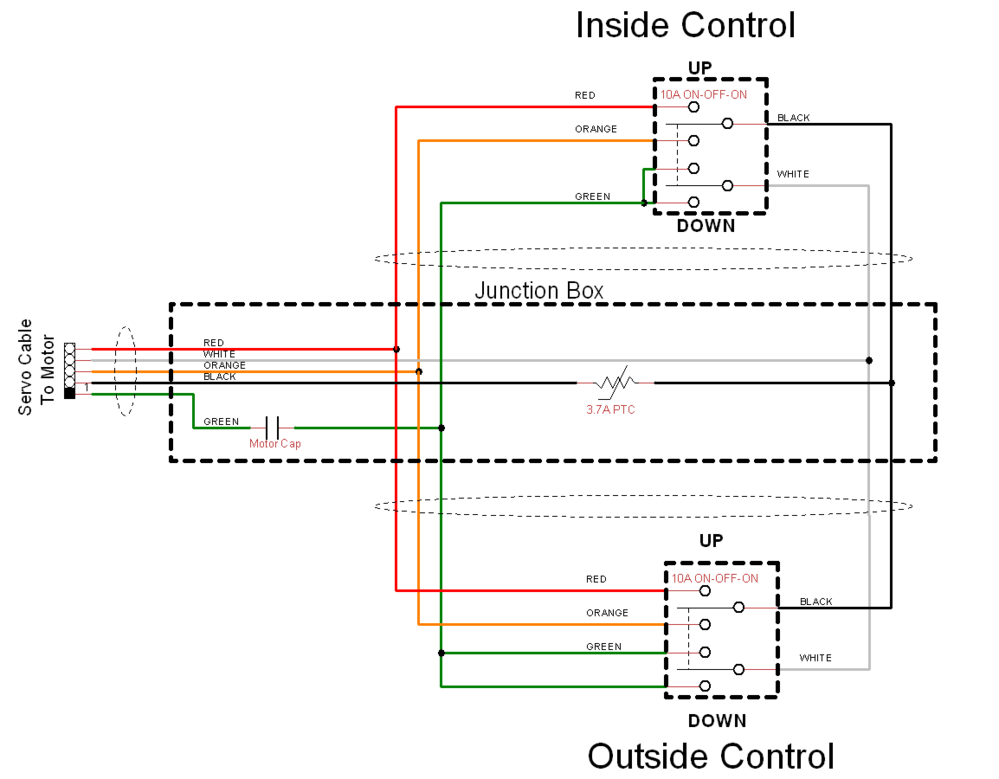

Next is to address the electrical side, low voltage control and the limit switch placements first. As others have done with these wide lifts, I intend to mount toggle switches on the inside and outside.

It has cost about $380 so far for plywood, hoist, pulleys, cabinet slides, levelers, toggle switches, and a couple of 5v relays.