I’m using this Lionel YouTube video for reference. Fast forward to the 7:54 time.

https://www.youtube.com/watch?v=_0McntbmQ9I

After connecting everything I’m not having success with the “toggle switch” activating the turnout. The video does indicate to solder the wires (9:47). My goal is proof of concept so these two wires from the “turnout” are twisted (9:24) together and then twisted together again (9:40). for the “Turnout” and “Constant” voltage wire. Once POC I have 12 turnouts modify.

At the 10:08 mark there’s mention of phased transformers. Do I need to accommodate/ implement phased transformers for this to work? I didn’t get that aspect as a take away since the phased video uses fast track. If I need to address, would another ZW have to be purchased or can a less expensive transformer be used? Maybe getting off track.

YouTube video on “Phasing” but using different transformer and something called a “block.” https://www.youtube.com/watch?v=iASQfnE6pCk

The “Constant” voltage wire is 16 gauge. Is that wire too thick with potential spacing between the wires so soldering is required?

Believe I’m using the correct ZW positive terminal. I verified the “toggle switch” works using track voltage with a different turnout.

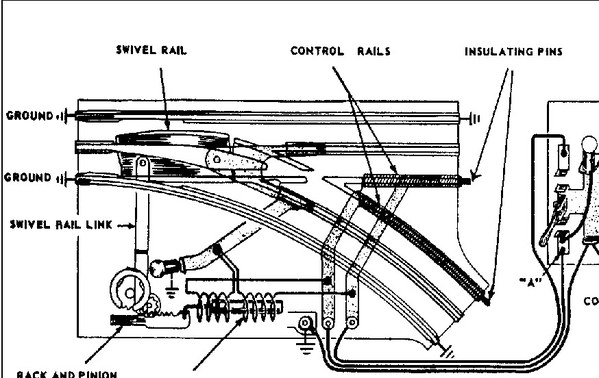

The other item noticed is by two “Turnout” wires are positioned on the opposite side of the coils.

Please see pictures for current set-up.

Any assistance is appreciated. Thank you in advance.