This is the story of my RR built essentially without any formal plans, just an over all idea for peddler freight service on multiple branch lines. I would not even want to hazard a track plan. But trust me the Domino effect has been in full swing at my place.

I started with a 30' X 40' "L" shaped switching layout then thought to go into an 10' X 15' alcove, then a 40' long wall looked unused except for a non supporting additional cinder block wall which took two days to remove. It just so happened that the last course of block removed allowed for passage around another corner to an additional wall which was great for another town.

Meanwhile at the other end of the "L", Jani G. asked me to help remove Joe's layout so I wound up with the White Top, so that prompted a sweeping U curve to tie it in on that end. So here I am with a rather large "C" shaped layout and I got to wondering, how much work to connect them. That thought got parked for awhile because they were on two different levels. Well it just so happened that a knee wall in my work room shared the same water level with one end of the layout so out came the Saws All and presto another storage yard.

While all this was coming together I noticed that a five foot reach was too much for a mid town yard. So I contracted with our HVAC guy to remove the tank water heater which was pinching the yard aisle and install a tankless heater in the corner out of the way. This allowed for me to flip over the yard bench work which created an access aisle.

This module flipped over to create the access aisle.

This module flipped over to create the access aisle.

After laying out some yard track I saw a way to jump over to another set of bench work frames to make another yard. That opened to door to drop a lower run to go under the original bench work to have a storage yard.

1% grade descending to the hidden staging yard

1% grade descending to the hidden staging yard

After firing up the laser I discovered that the storage yard was close to the same height as the knee wall in the work room so out came the Saws All again.

While laying the track in the new workroom staging yard I saw the opportunity to have our plumber relocate the water meter

and bring a second level storage yard in over top.

Two TTs serving 3 branch lines

Two TTs serving 3 branch lines

Done.

Now with all the new staging I found the need for a couple more turntables. Another module, another pair of TTs.

Now with a 32" TT I had a place to park my long locos which now called for another add on module.

Whisker tracks curved to clear aisle

Whisker tracks curved to clear aisle

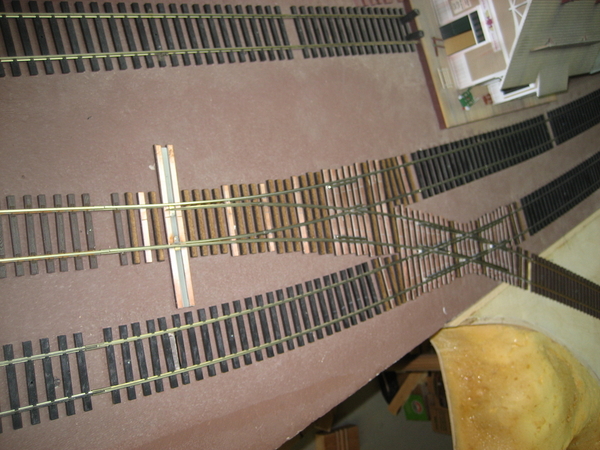

I did notice that a high town had some space under it so some more special siamesed switches..

4 curved 72" radius curved yard approach

4 curved 72" radius curved yard approach

provided a 4 track x 16' stub yard which was converted to a double ended yard with another long bridge.

<<New found yard space

<<New found yard space

Looking at the almost, but not finished RR wood work I saw how I could use a couple of display modules I had toured with. Due to the appearance of a case of claustrophabia coming on I mounted the new modules on wheels lying to my self how I could just move them out of the way if need be. (Never happened.)

Movable base for modules X 2

Movable base for modules X 2

Another display piece wound up butting to a TT feeder which was fine until I saw the need of another town. This led to some more of Brad's custom switch work

64" / 140" radius wye and crossing

64" / 140" radius wye and crossing

and suddenly there was 4' X 13' town on a sweeping curve with multiple businesses.

<<Extended end of line for one of the branch lines

<<Extended end of line for one of the branch lines

With much of the basement getting filled I saw this three rail MTH Galloping Goose running and thought it might be cute to see it running a little bit in the back ground on a shelf. Well that became a jumping off point of finally revisiting my 3 rail child hood. I now have two water wing loop to loop high rail runs one at 22" and the other at 55" with 75 and 35 foot runs with 3 or 4 levels of two rail depending on how you count them..

Despite the rambling description, what I now have is a feeder interchange from the "Big City" which brings in commuters and peddler freight service to five diverging branch lines in 2000 sq. ft. each on a different level and each with a run around and TT at the end of each line.

All walk around, no duck unders, 13 bridges, 115 turnouts, lots and lots of track, no idea, 9 DC power packs, 11 AC transformers, 120 toggled blocks, about 5k ft of wire then after discovery of on board battery R/C, the wiring stopped.

Now it seems like I need an electric locomotive service module for my juice jacks, the adventure continues...

Yes, Dominos can wreak some big happenings.

I had

I had

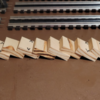

Note the square brass dowels

Note the square brass dowels