0 man, really, really nice. Love the workmanship. A joy to look at!

The atlas track can be a stiff bugger to work with. When I had to vertically transition for sharper 3 rail grades, I actually formed a vertical bow in a 40" length and centered the full length in the middle of the transition.

On the topside yard consider how laying the tracks out in gentle curves even an "S" curve to accommodate the access.

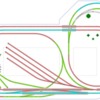

What about slicing into both ends of Ross' curved turnouts to make a mainline conforming curved turnout 4 way to facilitate an embracing yard. I picked up the idea from John Allen's G & D classic RR from a half century ago. It looks like this:

John Allen started his points right after the frog to compress the total foot print of his yard throat. Maybe something Steve at Ross would consider. I had to do this to get my four track yard started ASAP.

John Allen started his points right after the frog to compress the total foot print of his yard throat. Maybe something Steve at Ross would consider. I had to do this to get my four track yard started ASAP.

Maybe considering contacting Hiekel to check out the possibility of making a three way right hand wye to achieve an even shorter throat. Like this in a right hand configuation:

Real RRs have to build their yards within the available topography. The curved yard here is to provide an aisle funnel:

In an altogether different approach, is there a way to build an add on finger module so as to allow for a generous yard along a continuing wall?

Is there a way to come off a curve with a Ross conventional 4 way and then go through a wall into an adjoining room for tracks to run the entire length of the other room's wall.

Most of us already have so any cars that a short yard could be congested and discouraging.

The Curved Benchwork folks could make an extension module with a curved end to mate up cleanly with your existing benchwork.

Your accomplishment so far is self evident of well thought out planning. What you have already done proves you will make everything work out just right in the end.