My UP EC-4 Geometry Car shell that is housing my MooSoo vacuum is being changed. Which is why this car is taking me so very long to build.

The EC-4 resin shell is completed still needs painting but I needed to work on the electronics to illuminate 14 LEDS. The actual UP EC-4 has a horn with strobed front lights. I wanted to remotely control the ON/OFF vacuum control, too. To accomplish all that I needed an AC/DC Commander and a Railsounds sound kit. The AC/DC would have its feature set to strobe and one of the coupler controls would trigger a solenoid set over the MooSoo's ON/OFF button. The Sound board would provide the horn. My EC-4 is not powered and like the real EC-4 that is pushed by a diesel, I don't need the speed steps.

However, since I don't have a motor not sure how the Front and Back Lamps will operate. I mean how will they know direction?

Also I wanted to house the MooSoo charger inside a sliding side panel so I would not lose it. Great because I need to have an access to the Program/Run switch; in mine designated as P and R respectively.

Given the above, I designed a 3D resin printed electrical frame to house the ERR AC/DC Commander, Railsounds board, two 8 Ohm speakers (openings shown only) , the battery to the speakers (not shown)the program/Run switch and the MooSoo charger. This frame has resin plugs that fit into the car base slots(not shown)

The three pipes shown are used to convey wires from the trucks (on the track) and two sets of two ( 2) front LEDs Red and the White strobed LEDs.

Once the EC-4's side panel slides back you see what is above namely the charger plug holder and the P-program/ R-run switch and the sound board volume control pod.

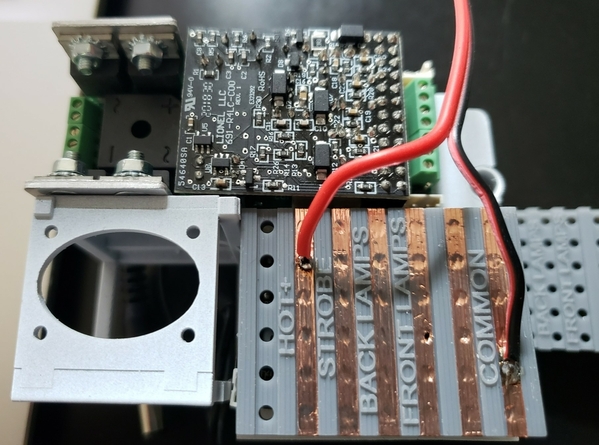

So with 14 LEDs that needed to be distributed between AC/DC Commander's SINGLE PORT for Front Lamps. Back Lamps, Strobe, Top LEDS, blinkers and the ON/OFF plunger as well as multiple Common connections, I needed a distribution panel. The panel is a Resin 3D print that fits over the sound board. The final resin panel (without the copper strips) is shown below

Below is my TEST Distribution panel. I added copper strips to a resin board with holes so I can poke wire into the copper and solder. The resin didn't melt. This is the test with 22ga wire.

Once all connections are made the panel will be resin-glued *with 405mn UV laser pen* over the sound board.

This is a custom electrical frame so I'm not sure how useful it would be to add to the 3D database.