Hi Carey , what an amazing find !

While not having Stirling Locomotive experience I do have a bit of a fiddle with normal Stirling stationary engines

The key to these are a few main points , most of which you have covered in your initial post , but I will restate them anyway...

Stirling engines are by their very nature very inefficient so the key to running them is to maximise heat transferrence and minimise friction loads .. so yep light oil everything and clean and reapply the minute it becomes tacky. Ensure all the rods are as straight as possible and running true, a little slop is better than being "bindy"

Next you will want to aid heat uptake as best you can using a good quality fuel and I use either fibreglass wicks , or cotton rope ones , I have heard of sisal being used as well . The key to the wick is not so much absorbancy of the wick material , but more the delivery of fresh fuel to the burn site by capilliary action .

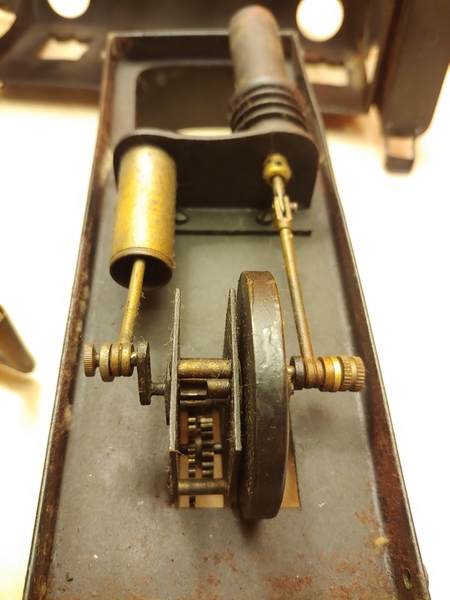

Temperature differential is what makes this little bugger hum and finding the sweet spot can take some experimentation , but in short you are wanting the fire side piston to uptake the heat from the burner and then expand the air inside the cylinder ( driving the piston) until it completes the expansion stroke and intakes more cold air from the displacement piston assembly . Yours appears to be the normal 90 degrees between the two , so make sure when you do fire it , you are rotating it the right way , they CAN run backwards ( but poorly)

I would probably look at cleaning the heat side cylinder and espescially the finned area , you want to get rid of as much heat from outside the expansion area as much as you want that expansion area to uptake the heat as efficiently as you can ... Some people even put a small block of ice on the displacement cylinder to further increase the differential between the hot and cool air ...

Cylinder clearances are also critical in maintaining the expansion of the air on the hot side and transferring as much cool side air to the cylinder ... if just slightly worn through use you can put a smidge of fine oil inside the bore/onto walls from below to help improve the seal and efficiency .

Running Stirlings without a load isnt that hard , but it might take a bit of experimentation with them under load as that really stresses their capabilities ... Always keep in mind it is the temerature differential and ability to harness it ( good tolerances,low friction) that will determine how it runs

I am a little bit jealous ( lol ) but then again I always am when you post your amazing early stuff!

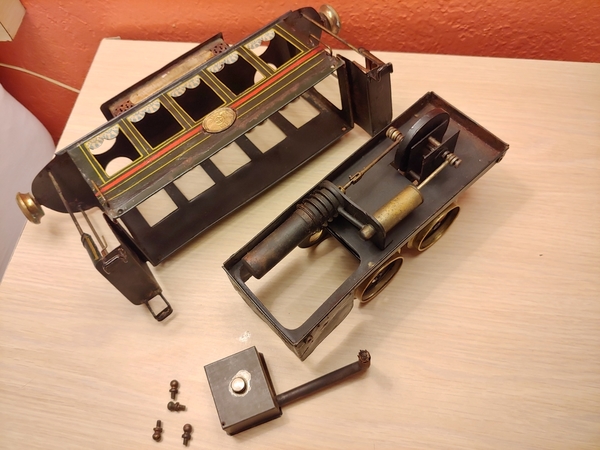

![0419192209[1] 0419192209[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/83931444266702682/primaryPicture/true/filePointer/84072378230197543/fodoid/84072378230210565/imageType/SQUARE_THUMBNAIL/inlineImage/true/frame/FIRST/thumbnail.jpg)