I've been handed a covered hopper to remove the body mounted couplers. Any way to do it easily? Thought there was a thread here, unable to locate it. Thanks.

Replies sorted oldest to newest

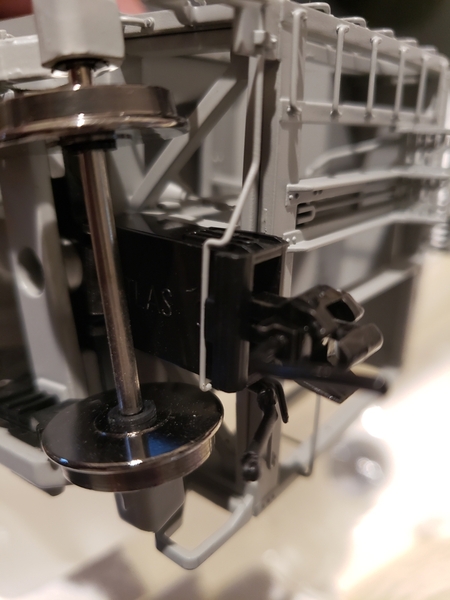

You need to work the tab retainer back with a small screwdriver or pick or something, or see if you can get a hold of it with a pair of flat bladed pliers. Once you get the retainer behind the tab you can pop the bottom out and the whole thing falls apart. If you dont care about saving it, then just cut the retainer loop and toss it. Depending on how many fragile bits are around the end of the car, sometimes its worth the $5 to cut the retainers and install new boxes if you want to put them back on.... the broken detail parts you'd have to replace when it goes wrong cost more.

I'm not sure if it's against forum rules to link to a YouTube video. I was just faced with tis issue- albeit with a 2004 Atlas O model(much easier to remove)- so I googled "replace atlas o 2 rail trucks" and there's a good video that basically shows the same thing that @Boilermaker1 describes above

@StevefromPA posted:I'm not sure if it's against forum rules to link to a YouTube video.

Of course not, hundreds of them are linked here. ![]()

@StevefromPA posted:I'm not sure if it's against forum rules to link to a YouTube video. I was just faced with tis issue- albeit with a 2004 Atlas O model(much easier to remove)- so I googled "replace atlas o 2 rail trucks" and there's a good video that basically shows the same thing that @Boilermaker1 describes above

This one?

Are you trying to 3 rail it? Or just change the Stiff spring in the box for a kadee one?

If you're 3 railing it, then the cut lever will probably have to be trimmed back to clear the lobster claw. It may not be glued in and you might be able to wiggle the mount out of the end of the car.

If you're trying to just change the spring but keep the scale coupler, then I would try and work around it.

I just get a small flat blade screwdriver and push it under the retainer and bend it till it pops off. I've had a few of those retainers end up in a different room, they really do fly and without eye protection you could hurt yourself. 90+% do no harm to the pocket but a few do break it.

Hafta laugh. I am pretty handy, mostly scratchbuilding my own locomotives from brass and steel. Today I am finishing up an ancient Taylorcraft fuselage. I overhaul my own aircraft engines, and have a complete machine shop.

These couplers baffle me! I simply destroy them when removing, and pitch the cut pieces in the trash. Then plug, cut,, re-drill for Kadees or Monarchs or whatever, and onward.

Sometimes they come off easily when pushing the retainer back, and sometimes not.

You don't need to remove the cut lever if just changing to Kadees. DO NOT cut it. Once you open the box, you can unscrew the box from the inside and slide it out past the cut lever with no issue. I have done it at least a dozen times.

for Kadees, rather than redrill, I use #43 drill and elongate the rear of the Kadee box toward the front so I can use the existing screw holes. then I install the Kadees with 2 MM X 8mm (metric) screws. this jusually matches the the threaded holes exactly.

@bob2 posted:Hafta laugh. I am pretty handy, mostly scratchbuilding my own locomotives from brass and steel. Today I am finishing up an ancient Taylorcraft fuselage. I overhaul my own aircraft engines, and have a complete machine shop.

These couplers baffle me! I simply destroy them when removing, and pitch the cut pieces in the trash. Then plug, cut,, re-drill for Kadees or Monarchs or whatever, and onward.

Destroy them and put them out of their misery. What few Atlas cars I have kept - re-drilled and tapped for 2/56 for Kadee and no worries about anything afterwards.

@bob2 posted:Hafta laugh. I am pretty handy, mostly scratchbuilding my own locomotives from brass and steel. Today I am finishing up an ancient Taylorcraft fuselage. I overhaul my own aircraft engines, and have a complete machine shop.

These couplers baffle me! I simply destroy them when removing, and pitch the cut pieces in the trash. Then plug, cut,, re-drill for Kadees or Monarchs or whatever, and onward.

Boy do we agree on that! They are designed to be put together easily and not be maintained. Sounds like many automobiles in the past 25 years.

Thanks for all the help guys, appreciated!