I’m using Lionel Fastrack in my 18x24 layout outer loop. I’ve tried any number of wiring connections and still have issues with quality DCS signal. There’s typically a 10 second delay when operating any MTH engine. Speed control is therefore very awkward.

Replies sorted oldest to newest

My personal experience with DCS is that compared to Legacy, it's not especially robust or fault tolerant. You could try tethering the remote to the TIU with a telephone handset cord (remember those?) to see if your delay is arising from that part of the communication chain. Assuming the joints between your track sections are tight, I don't know of anything specific about Lionel Fastrack that would reduce the signal.

You also might try re-posting your question in the MTH DCS Sub-forum. I think the folks who hangout there have more perserverance than I do! Good luck!!

I'm kinda' with Ted, I think checking the quality of all the joints is key. Also, if you're having signal issues, have you looked at the recommended wiring practices for DCS?

Thanks for both of your responses. I have not tried tethering the remote directly to the TIU. I’ll try it. I also made sure each track section is firmly connected.

I’ve also tried the direct wiring techniques documented in the DCS companion book. I don’t believe it’s the wiring. In addition, I went online and viewed a couple of videos on Fastrack. One approach was to bend slightly the center pin and the outer rail (long one) toward each other for a tighter fit. I also viewed a technique on the Lionel website about soldering a wire under each track section to ensure connectivity. Those two videos would indicate to me that there’s a known issue with Fastrack and connectivity reliability.

When I used MTH RealTrax, I never had a DCS signal issue.

So, my options are to pull up each track section to ensure pins are tight and test each section as I reassemble the loop (if that’s even possible) or use totally different track(expensive option). I might even just use tubular track to see if still have signal issue.

BTW, I used a multi meter and tested each section of Fastrack and I get same voltage reading at the track as I see the voltage on the Z4000 digital reading.

Have you done a Track Signal test ?

Does your loop have Insulating pins dividing it into blocks ?

Not familiar with Fastrack. Are there any turnouts in the loop ? If yes. Are they powered separately.

The delay your experiencing. Could be the remote not find in ding the TIU. Tethering it will let you know. I’m thinking track signal. When you issue a command. The engine won’t respond if the signal is bad and will just keep doing whatever it’s last command was.

Thanks Dave for your feedback.

yes, I’ve run the signal test and it’s very erratic.

I have no blocks in the loop

yes I have two turnouts in this loop and they are both powered separately from Z4000 14v.

on numerous occasions the remote doesn’t find the engine. But when it does, there’s typically a 10 second delay, then the engine starts. When I sound the whistle, it sounds for an extended period. When I increase speed, or try to, engine doesn’t respond or takes several seconds or I get an error that engine is not on the track. It’s strange because the front and rear couplers function immediately as well as the direction function. The engine will also shut down immediately. It’s not engine specific, it happens to every MTH engine I try to run…tested about 25 of them.

I have a test track close to the TIU so there’s a short connection from TIU to track. This is where I load each engine into the remote and it works as designed and the engine functions all work properly.

I just don’t get it…I get 20-22v at each track section so why isn’t there a consistent DCS signal? I’m not an electronic engineer so I don’t know how the digital signal overlays the power from the transformer through the TIU to the track.

My track and engine rollers are clean.

I don’t know the exact number. I’m thinking about 30 feet of track for each block is what’s recommended. One set of feeders to each isolated block. You can have multiple feeders on the sameTIU output. After you give the engine a command. It needs a path back to the TIU to acknowledge a command was given then it executes it. Pretty much. The simpler the path. The better it works.

You mentioned no blocks. Plus not sure what your turnouts are feeding as far as trackage. If you can break the layout apart easy enough. Work on one just one section till you get a 10. Connect up another and use an insulating pin on the center rail or however it’s done with Fastrack. Test Again and hopefully just keep moving along till it’s complete. But always go back and test your previous work.

You may just have to much going on trackage wise for one channel to handle with multiple feeders hooked to the same loop. The fact that you can add your engines on your programming track but not your layout. I experienced much of the same when DCS first came out. I had to clean up a lot of wiring to get it to work. Your Track Signal Test function is your best friend in getting this fixed.

Thanks Dave, you’ve given me something to think about. I’m using a barrier strip which takes one wire from TIU, then feeder wires go to track connections every 6-8 ft on the loop. Are you familiar the Fastrack connections under the track? Do you think I should solder the wire connectors to the post? Do I need to alternate the ground connections on the outer rails? Someone told me to use telephone wire for my feeder connections. I’ve been using 12-14 g stranded wire.

I like your idea to test the DCS signal for each section connected to a feeder wire. More of a systematic approach then my typical helter skelter impatient approach.

"When I used MTH RealTrax, I never had a DCS signal issue."

Different size layout/loops? I recall when others had these problems, they were solved by electrically isolating sections of track greater than 20-30 feet, as mentioned above, and running star wiring pairs of wires to each isolated section directly from the TIU.

@Bogs posted:BTW, I used a multi meter and tested each section of Fastrack and I get same voltage reading at the track as I see the voltage on the Z4000 digital reading.

That's only useful if you have a load on the track, with no load a high resistance joint will not show up with a voltmeter test.

@Dave_C posted:I don’t know the exact number. I’m thinking about 30 feet of track for each block is what’s recommended. One set of feeders to each isolated block.

It's not the length of track as much as the connections in each block.

A couple of key points from Barry's DCS document.

- Attempt to limit the number of track blocks or sidings from a single TIU channel to no more than 12-15. If using a Rev. L or later TIU, that may be increased to 20-24.

- Limit track blocks to no more than 11 or 12 track sections where sections, long or short, all count. If sections are all short, consider soldering connections between sections to make longer ones. Regardless, track blocks should not exceed 100 feet in length.

Oh…hmmm. I don’t get any voltage drop between track sections, so I know I’ve got sufficient power throughout the loop. It’s the digital signal that baffles me.

I think I’ve convinced myself based on responses on this forum to unscrew all the track on the outer loop, lift off all the track, replace and test a section at a time for signal strength and continuity.

Thanks Dave. I’ll get her done.

@Bogs posted:Oh…hmmm. I don’t get any voltage drop between track sections, so I know I’ve got sufficient power throughout the loop. It’s the digital signal that baffles me.

But do you see no voltage drop between sections when you add a significant load at various spots on the track? FWIW, the DCS signal characteristics baffle a lot of people!

@Bogs posted:So, my options are to pull up each track section to ensure pins are tight and test each section as I reassemble the loop (if that’s even possible) or use totally different track(expensive option). I might even just use tubular track to see if still have signal issue.

FWIW, I've had DCS on my long narrow (35 feet by 4 feet) tubular track layout with numerous postwar 022 switches and sidings for 3 years and never had any problems.

I believe I have the latest version of DCS including the TIU and handheld remote, and did star wiring as recommended in Barry's book on DCS.

In fact, I'm so pleased with DCS that I don't plan on adding TMCC or Legacy to my layout.

I have a few Legacy locomotives and run them using the LionChief Universal Remote, which I find very satisfactory.

Arnold

My last layout had a loop of realtrax and a loop of fastrack. The realtrax I cleaned every one to two months, the fastrack had to be cleaned everytime I ran trains. I currently have two loops of snaptrack and never have problems, clean the track about every 6 months or so. Apparently DCS really hates dirty track and fastrack was the worst about getting dirty here in my southwest location.

And it was super loud no matter what I did.

I don't use it anymore and no more problems with my DCS system.

I have had my present Fastrack layout for nine years. It is 20' by 16' in a U shape with two mainlines. I have had all 10s for all those years. I hardly ever clean the track; maybe every six to eight months. I run DCS on the two fixed channels, with ten blocks on one and twelve on the other. I followed Barry's recs, using ten to twelve track joints for each block. @Lou1985 and @gunrunnerjohn are giving you good advice.

I didn't have DCS signal with Fastrack, I got rid of it because of the noise.

@gunrunnerjohn posted:That's only useful if you have a load on the track, with no load a high resistance joint will not show up with a voltmeter test.

Hey @gunrunnerjohn...

I have a stupid question. When you (in this case) talk about putting a load on a track block, are you talking something as simple as an 18V bulb or maybe a DCS engine that's in idle after start up?

Well, personally, I have some big honkin' 75W 8 ohm resistors that I use for testing transformers or for such load tests. You need to put at least a couple of amps of load on the track to get a real test. Then you check each joint for voltage drops. With multiple drops, you'll also have to move the load around to cover all the bases.

Attachments

Thanks John!

"The realtrax I cleaned every one to two months, the fastrack had to be cleaned everytime I ran trains."

If you operated locos with traction tires on the Fastrack and without traction tires on the Realtrax, that might be a contributing factor. It's probably the locos/rolling stock, not the track is my guess.

For the layout I put up for Christmas, I use 4 Fastrack switches and use track power (no chokes on the switches). I have not had a problem with DCS on this layout.

My main layout (about 350 feet of track) has always had some issues with DCS while TMCC/Legacy have been flawless. I followed the star wiring recommendation and had 1 power drop per block with very short blocks (at most 8 pieces of track. I also use Fastrack on my main layout. I have been using aux power for the switches.

I am in the process of ripping up my main layout to do a major reconfiguration of the track plan. I will be interested if I am able to eliminate the DCS issues when I am done.

@Landsteiner posted:"The realtrax I cleaned every one to two months, the fastrack had to be cleaned everytime I ran trains."

If you operated locos with traction tires on the Fastrack and without traction tires on the Realtrax, that might be a contributing factor. It's probably the locos/rolling stock, not the track is my guess.

Same loco's on both, and yes they all had traction tires. Fastrack works for some people, did not work for me. The deal breaker was the noise though.

@Landsteiner posted:"The realtrax I cleaned every one to two months, the fastrack had to be cleaned everytime I ran trains."

If you operated locos with traction tires on the Fastrack and without traction tires on the Realtrax, that might be a contributing factor. It's probably the locos/rolling stock, not the track is my guess.

@Darrell posted:Same loco's on both, and yes they all had traction tires. Fastrack works for some people, did not work for me. The deal breaker was the noise though.

CHRISTMAS coming has me cleaning all wheels and track before set up. ![]()

The top layer is Reatrax with the MTH NATIVITY ENGINE ( with traction tires ) and LED lighted Nativity cars. Run by Z1000 and DCS handheld remote. ( approx. 25 ft. of track. )

Lower level is Fastrack with the LIONEL POLAR EXPRESS ENGINE ( with traction tires ) and POLAR EXPRESS LED lighted passenger cars. Lionel plug and play transformer with handheld remote that comes with the set. ( approx. 35 ft. of track )

For whatever reason the Fastrack will develop a layer of black in a very short period of time and the Realtrax will run for several weeks with very little black accumulating.

DON'T KNOW WHY . ![]() But I do recall several posts on the forum highly recommending using the MTH traction tires when the original Lionel's were shot. Maybe the traction tire material has a different makeup causing the blackening issue IN MY CASE !?!

But I do recall several posts on the forum highly recommending using the MTH traction tires when the original Lionel's were shot. Maybe the traction tire material has a different makeup causing the blackening issue IN MY CASE !?! ![]()

@Dallas Joseph posted:For whatever reason the Fastrack will develop a layer of black in a very short period of time and the Realtrax will run for several weeks with very little black accumulating.

DON'T KNOW WHY .

But I do recall several posts on the forum highly recommending using the MTH traction tires when the original Lionel's were shot. Maybe the traction tire material has a different makeup causing the blackening issue IN MY CASE !?!

When I pack up my Christmas layout each year, I have to do a thorough cleaning of the Fastrack. It always has a heavy coat of black residue. I run both MTH and Lionel engines. Some years it is only MTH other years only Lionel and some years both.

I have a few pieces of Realtrax from some set that I bought. If I run my finger over the Realtrax rail, it does feel a bit smoother that Fastrack rail. Perhaps the Fastrack is more abrasive on the traction tires?

We need some university to undertake a study of traction tire wear on various brands and types of track. ![]()

Many good thoughts and suggestions here... Then comes the famous BUT.....

Is there a reason for the 10 second delay in the original post. That is an issue I don't remember seeing before. Maybe the data packets are going to the moon and back several times?

Getting some great feedback. I need to get busy.

The 10 second delay for engine start ups is weird. Operating any of MTH engines is tough, especially with speed control. I wish there was a counter on the DCS remote roller. It’s insane how I have to continually roll it just to increase speed 1 mph.

I’ll follow up once I unscrew all the track and disconnect it. I’ll test signal strength one section/one block at a time.

I sincerely appreciate everyone’s feedback. Really showcases the strength of this forum. BZ to OGauge Railroading and the train enthusiasts.

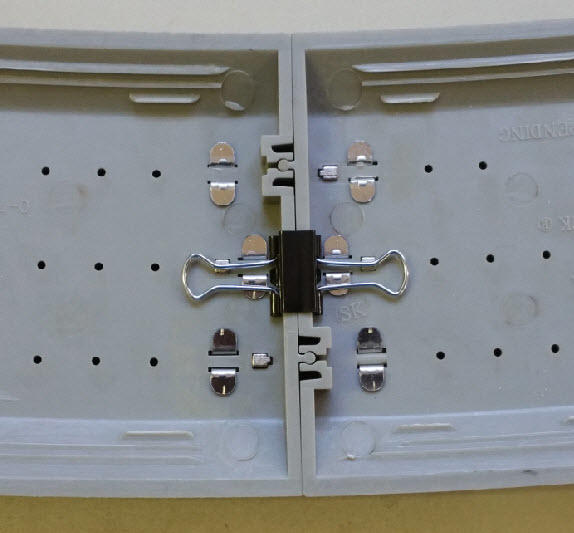

Since you're pulling up the track anyway, you might consider wiring and soldering several of the track sections together to help eliminate any connectivity issues, as you pointed out earlier. You don't have to connect every section this way, but you should draw up a plan and show which sections are soldered together and where the breaks are. You can also use a binder clip to help keep track sections tight and in place

I'm not a huge believer in excessive track screwing for Fastrack, especially on switches. You can easily overtighten and twist one section and create resistance and connectivity issues. I only use a track screw every few sections as needed to keep the track in place and only tighten lightly.

I also use 30" FT straight sections wherever possible to also help eliminate any connectivity issues.

You mentioned using a barrier strip and it looks like you may be running a common ground. I run both Legacy and DCS on my layout with no issues. FWIW, I run my TIU outputs (red, black) to a distribution board like the one pictured and then run paired wire feeders to a two terminal block just underneath where my feeder will go. I then run 18 gauge wire from the terminal block to the tabs under the FT and I solder all connections. I also solder in a TVS suppressor to the terminal block for extra protection.

I have 10's most everywhere on the layout and I have not needed to cut the trackage into blocks, but I could easily do that if I were still having DCS signal issues by simply cutting the center rail with a Dremel and cut-off wheel about 4-5 track sections on either side of where each feeder is located.

Attachments

@gunrunnerjohn posted:Well, personally, I have some big honkin' 75W 8 ohm resistors that I use for testing transformers or for such load tests. You need to put at least a couple of amps of load on the track to get a real test. Then you check each joint for voltage drops. With multiple drops, you'll also have to move the load around to cover all the bases.

Hey @gunrunnerjohn...

I checked online and I can get 4 - 100W 8 ohm aluminum case wire wound resistors for $9. I'm guessing these will do the trick for putting a load on the track for voltage drop testing?

BTW...I use fast acting 8A magnetic circuit breakers on my main power feeds. I'm thinking I might have to bypass these once I put a load on each of the track blocks being tested?

Should I take the TIU and TMCC out of the circuit as well?

@Bogs posted:I’m using Lionel Fastrack in my 18x24 layout outer loop. I’ve tried any number of wiring connections and still have issues with quality DCS signal. There’s typically a 10 second delay when operating any MTH engine. Speed control is therefore very awkward.

@gunrunnerjohn posted:But do you see no voltage drop between sections when you add a significant load at various spots on the track? FWIW, the DCS signal characteristics baffle a lot of people!

I give up Bogs. ![]() John says the cha bracteristics of the DCS signal BAFFLE a lot of people.

John says the cha bracteristics of the DCS signal BAFFLE a lot of people.

I have no blocks , no special enhancements and no screwed down track. on my Realtrax layout of over a hundred of feet of track ,on carpet ontop of some inexpensive plastic tables and over and under plastic bridge supports . ( A layout consruct that would have most forumites grabbing for Valium. ) ![]()

Full DCS system . No issues but I do have absolutely clean whells and clean track and I even use the electrically conductive oil (the jury still seems to be out on that yet ) for ALL axles and anything connected to the middle rail and the outer two wired together rails.

Maybe what Vince talks about the Fastrack being not as smooth as the Realtrax might have some bearing on the issue you are having.

@Junior posted:Hey @gunrunnerjohn...

I checked online and I can get 4 - 100W 8 ohm aluminum case wire wound resistors for $9. I'm guessing these will do the trick for putting a load on the track for voltage drop testing?

BTW...I use fast acting 8A magnetic circuit breakers on my main power feeds. I'm thinking I might have to bypass these once I put a load on each of the track blocks being tested?

Should I take the TIU and TMCC out of the circuit as well?

No need to take anything out of the circuit. One of these will give you about a 2A load, two in parallel will give you 4 amps. That won't strain anything, and will allow you to do your circuit testing. Remember, there's normally a load on the track when you're running!

Excellent.....Thanks GRJ!