Originally Posted by Moonman:

Well, the snow stopped a little while ago, so it's machine time for this load. I'll mess with it later if I don't take a big nap.

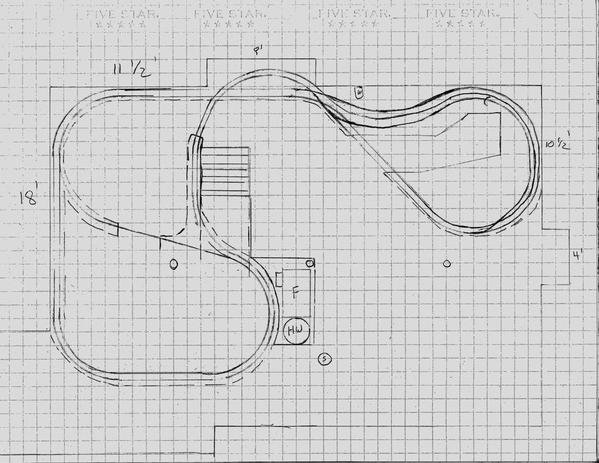

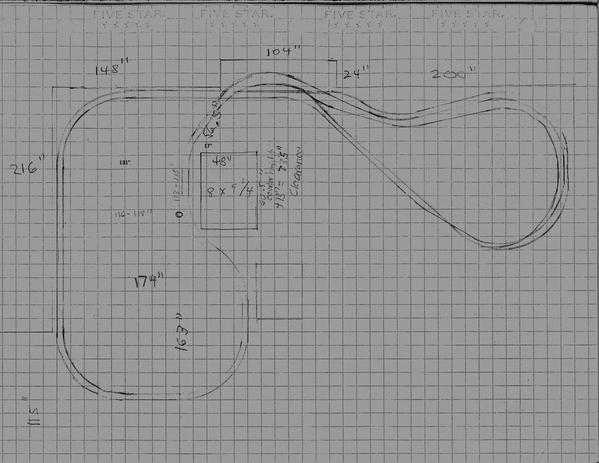

I'm just counting blocks and guessing. Thanks for the stair location details. I was using 106 coming out of the South. It won't have to curve much. I had it parallel to the stairs, but it looked like you wanted a bump next to the stairs. If you want a narrow shelf, that shouldn't be a problem.

Have you decided on which track you'll use? I discovered much to my chagrin that the center to center spacing on the larger curves are 3.5" versus 4.5" so the track plan has different spacing. Do have a preference for the spacing? I suppose on the large curves, you can get tighter than 4.5" as there is not much hang, except for the big boy.

Wow - you've been busy! My plan is to go Gargraves Flex with Ross Turnouts. I'm concentrating on BIG cars - the Lionel 86' & 89' units and likely either the 18" MTH or 21" K-line streamliners - depending on availability. I'd prefer the K-lines - in particular the High Levels - they would be more period accurate for 68-71. At that size, I'm guess 4.5 would be more ideal. To start I want to focus on building two big trains - I can add some misc. 50' boxcars or piggybacks later on.

Originally Posted by Moonman:

Here's the corrected step location. The steps are ok for when they were built. A 7" rise worked out. Not really that steep.

I measured when I got home - 8" rise, 9" step. I re-measured everything to inches. I'll scan it and get the inch measurements up tomorrow morning. I'm off by inches in a few places.

Originally Posted by Moonman:

So, if your table height is 30", the rise to 37.5 or 38.5 to the bridge and overpass at the alcove, the incline under the stairs should stay under 36.

Going around the stairs you would raise the table height 42" and 50.5" at the bridge and overpass. The large radius doesn't make it look silly.

What table height do you want to have? I vote for 42" and get some step stools for the littles.

I'm thinking 35" lower level and 42" upper level. That feels about right.

My vision of elevation is a bit different than the representation here in SCARM - obviously something that was difficult to convey in a pencil drawing - I'm actually thinking the reverse elevation-wise - My thought was that the level coming around the stairs would be at 35" and that the around the wall (east side) would be at 42". So inside the alcove, the stair track would tuck underneath and re-emerge, not go over the top and back across.

Where the east loop begins - my thought was that the inner loop would cross over itself - the lower level from the stairs would follow the outer level upper along the North wall.

To make things more interesting: the lower level outer loop (inside curve in the alcove) would feature a switch somewhere here to initiate a third track for a return loop which would follow along the Upper outer and lower inner along North Wall at 35" height. While moving along the North wall - the outer loop would begin it's descent - while the inner loop would begin it's climb to 42".

Once through the switch, the Outer lower loop - exiting the alcove, would somehow cross under the inner upper loop and the two would cross two separate bridges. Once across, the outer loop at 36" would include a switch to tuck under the upper inner loop to create the connecting end of the reverse loop.

If the east wall were at 42", that would create an upper level that I could surely put a cool yard in below with an entrance from the south inner loop that could span that 18' wall at 36" creating a nice two level effect.