Soldering. Oh yes I forgot that one. I learned how to solder with Dad's iron. It was not electric. You had to turn on the gas stove, and lay the business end of the iron in the hot flame. Then you had to know when it was hot enough, quickly move it to your work and make the solder joint. Yes it was time consuming and a bit trial and error. I'm not sure how well Mum liked soldering going on in the kitchen. ![]()

Oh wow! I never had to go that route - although my first cruddy radio shack iron wasn't much better - heated up so slow it was basically worthless.. I'd have been better off heating it under a flame!

The kids are lucky - I picked up a well used weller unit from a buisness liquidator about 15 years ago. Digital temp setting and readout. Its probably 25 years old, but it gets it done.

I was also teaching him about continuity and how to test track to see if the center rail is isolated using my multimeter.. Now, thats not to say he "retained" much of that lesson... 9 year old brains are kindof like my Husky out on a walk.... SQUIRREL!!

What defines "proper"? Why is one layout proper and another not?

Proper as in - permanent... as opposed to just setting up track and running for a day or two and then tearing it down. Something deliberately planned.

Think more along the British useage in common vernacular - "A proper breakfast as opposed to grabbing a bagel and coffee".

Now - before this thread devolves into debate as to what specifics constitute a "proper layout" - let me state that for my use - *this* layout and this use of the term means: thought out, planned and then executed to be at least semi-permanent and affixed to benchwork with some sort of cohesive scenery plan and theme.

Our theme (at the moment) is Steam/Diesel transition around the 1950's.. but we may take liberties as we go..

My parents (not extremely mechanically inclined) felt a need to lock "dissassembly" tools up to keep me out of them while unsupervised.

No pliers, wreches, or screwdrivers (Ha, they never caught on to the Boy Scout Knife's screwdriver.. but it was limited) I only had free reign over the floor grinder, hammer, saw, drill, woodburner, carving tools, & nails. All limits stemming from my pre-school removal of all near all of our doorknobs and pushing the square shaft in until the shaft and other knob was laying on the floor in each closed room. I got at least one tighter, but didn't know about lefty loose, righty tight yet. 🤣 Then there were those first reversed threads on the bicycle pedals ![]()

![]()

![]()

![]()

Anyhow, I took a HUGE risk, did not mind the rules, knew the box was open and repaired Mom's record player, broken for a few years, but she refused to let me try. The reject/start handle snapped, I made a small mending plate fit and added a tiny block of oak for a handle... it took total disassembling and reassembling in under 1-1/2 hrs to not be caught in the act. I stacked her fav records and after her return, played music until she noticed they were whole album sides playing.... after a scowl/grin, the boxes remained unlocked. (summer after 5th? ) ....I was the good one. My brother the cop and sister the social worker were the real trouble makers. They brought 7 strays home to live with us.

..... stray people ![]()

I have soldered with screwdrivers, nails/ and fat leather sewing machine needles; hat pins and even solid wire using propane torches/butane micro torches.... but I never used a team saw, and avoid table and cicular saws like they are sharks. I've seen too many short digits. I like chop saws though.

At the same time the coolest saw I ever ran was a Milwauke metal cutting circular saw. Imagine cutting 1/2" I-beam or bar stock with an only slightly heftier version of your normal circular saw. It took 7-10minutes on an automatic industrial chop saw at an early job (ran 4 at once)

All of a sudden giant gasoline driven cut off wheels messes are gone. Just "machine shop chips" to sweep up.

Tell the kids about weld flash & the build up of it, and drive it home not to watch torches, you may not be there when they see it at first... "eyeballs itch inside, and ache so bad you'll want to tear them out". (Grandfather's cobalt lensed, leather temple & cheek guard saftey glasses made this a very memerable lesson. Too cool.) Ha!, I recall hiding my eyes from the tv when Herman Munster and Lily were patriot welders. As an adult it's worse. I habitually turn my head, close my eyes, or nod to drop my mask down if I have a hat on, if welding or torchwork is on TV or anywhere near me really.

I even found myself doing it watching operating welding accessories on layout videos.

I have an uncle that had rebuilt and installed a V-8 in a car by second grade, mostly himself (huge kid, huge man... HE is the cherry picker if heads are off). He sold it and bought another. Repeat.

Grandfather was TEACHING welding by 17 and had me acting as an automatic drillpress monkey pre-school....and Gramps (other side, train guy, "all his fault") was either logging or in the steel mill where he would contently remain. Invited to, but never stepping into the hassle of management preferring to work with his hands and yell at lazy workers about screwing him, the company, and the union on his own accord ![]() . (union means "team", no i )

. (union means "team", no i )

I sold woodwork for spending money. Early, it was woodburning signs, later clocks and odds & ends, a couple tables & a chair. (I made money in every school shop class I took; even drafting. I kept one table (still used) and a small fake electric guitar I would seranade the girls with in acts of hilarious public humiliation (it worked well enough ![]() ) I sold the rest. (a friend bought a table with my name on it at a yardsale about 20 years ago thinking it was stolen, as I had been robbed a few years prior.) (if you include my youth my already varied adult careers it all becomes very wide spread set of experiences)

) I sold the rest. (a friend bought a table with my name on it at a yardsale about 20 years ago thinking it was stolen, as I had been robbed a few years prior.) (if you include my youth my already varied adult careers it all becomes very wide spread set of experiences)

I wonder when Da Vinci's parents unlocked his toolbox 🤣

We got our switches... but we've all had the flu this week and I'm the current victim - so they won't be going in for a while... Hoping to feel better before Monday.

Get well soon!

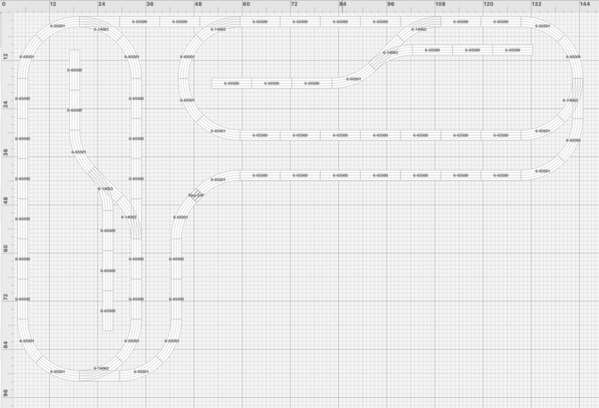

Was feeling a bit better on Sunday and laid out our track and switches (Pics to follow).. learned a lot... I learned that I need a bigger space to accomplish what I want. I'm back in bed sick today (wasn't feeling as well as I thought) , so - I got back to the drawing board... or railmodeller in this case.

This is based on the "Two Sheets to grow on" layout over at CTT website.. I think I'm going to see if I can add the required 4X4 expansion by moving things around in the basement...

Attachments

If you can fit an 8' x 12' x 4' wide L , the layout options really open up.

Here are some track plans from Thor Trains for an L - make O36 and maybe some O48 work.

Edit: Oops - forgot you changed to O - so O42 and O31

Well - turns out I can only fit a 3' extension... did the initial work measuring today.. But - its still waaaay more space.. I already modded the above layout to fit - easy as it was only about 3'6" of extension..

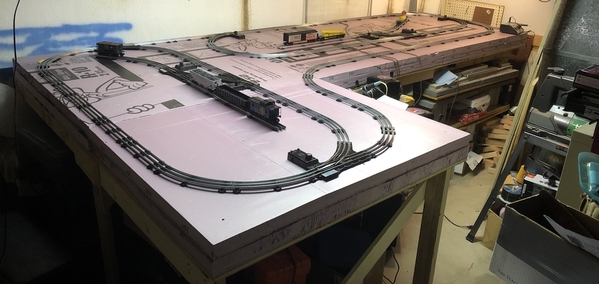

Started feeling a bit better toward the end of the day so I decided to finish the bench work, update my control area and lay track.. I’m tired!

Now this is what I call a layout! Still need several feed wires for blocks and sidings and no switches are wired...

Attachments

I'm glad you are feeling a lot better! The layout looks great!!

Is the wiring schematic included with the plans?

I was looking at it thinking what an interesting challenge it would be for conventional running having 3 trains on the table, 1 on each inner loop and one to run the perimeter line.

The two loop trains (local short lines) could run at once. Then, move one off and bring in the train on the outer.

Kill both loops and run only the outer, a high speed express.

Only wiring is what I come up with in my head... ![]()

I'm thinking something along those lines - isolating the loops and running the outside on a different block so I can park the trains inside a loop while running a mainline from town to town... Not sure - I'll play with it..

In a perfect world I would use block detection so as to keep the mainline running while stopping the looping trains. But I'm not that advanced yet.. ![]()

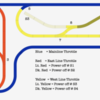

Looks like what I was thinking of Carl, Updated the track plan with blocks, switches, and power shut-off for the sidings..

I have no idea if I'm doing this right - or if there even is a "right" way... but this is how I see it at the moment..

Since I have two ZW's - (Only using two throttles on each, the other two on each for accessories):

ZW1 - T1 = Mainline

ZW1 - T2 = East Loop

ZW2 - T1 = West Loop

Then I can use simple SPST switches to turn on or of power to the four sidings.

Attachments

This has been troubling me - I am assuming that the train passes from one throttle control to another - that just seems strange... but then again - I'm the neophyte.

So - You just leave your mainline throttle set, and then speed up the loops to match before they pass into that block? How do you avoid jumpy speed changes?

You do your best to match voltages in conventional. A thermosistor/inrush limiter might be worth playing with. I've never really "played" with one but it's possibly a nice way to slow a gain in speed. But it may slow it too much initially too. I've seen complex uses and swaped them, just never played around with them.

(resistance is high at start, and tapers off as the component self heats. Lionel used them in post war stations with station stops so when the unit throws full power back at the loco, it doesn't jackrabbit start. These circuits also knocked voltage to about 5-6v to keep the e-unit active during a stop so it would not cycle)

The speed change between blocks gets easier as you get used to it IMO

Every little bit is progress!

Escher posted:This has been troubling me - I am assuming that the train passes from one throttle control to another - that just seems strange... but then again - I'm the neophyte.

So - You just leave your mainline throttle set, and then speed up the loops to match before they pass into that block? How do you avoid jumpy speed changes?

Your concern is valid - two things have to be to addressed when a train passes from one transformer to another

- First they absolutely must be in phase - see the attached from the 1954 Lionel Operator's manual to phase the two ZW's.

- The voltage must be close to avoid bridging - adding the two transformer amperage together when there is too great of a voltage difference

This why you see conventional operators have volt and amp gauges to monitor the outputs. There are some nice threads on this topic with some inexpensive analog meter sources.

The approach that I started with was trying to avoid these issues. But the track plan doesn't lend itself to that.

Your approach is not wrong, as the AC motored conventional equipment can tolerate the minor differences when traveling from one transformer block to another. Lighted cars will lose bulbs.

Definitely phase the two transformers and mark which side is hot on the plug. The side that plugs into the narrow slot on a modern outlet when the transformers are phased. The wide slot is neutral (train Common) and the round hole earth ground.

I would recommend that you build a gauge panel for the engineer to have the ability to monitor the output. I suppose they would only be needed for track power (A & D) , as you could preset B & C for fixed voltage accessory uses with a handheld meter.

Attachments

Carl, Those are some excellent reminders even for folks who have run trains for years or have been trained in electronics and have worked a career in the field; myself fitting into all these categories. In the anticipation of getting trains running, it is often easy to forget any of these and then wonder why there are troubles. Yes, the meter panel is a really good suggestion. And phasing is a must!

Thanks Gents - Lots to think about...

Plus - now I have to go check my ZW wiring. I have one cord that I need to replace - but I also have to check the previous cord I replaced to see if I have the prongs connected correctly. Never gave it a thought with AC before..

I'll likely wire up a panel with ammeters and volt meters for each throttle as well.

....aaaand I still need to order a couple more switches before Tinman closes up shop for the year!

Question - If I connect up the two loops via switches - as shown below - I would need another block for just the black area, correct? But each of the two new switches would be contained in the red or yellow blocks.. that would still allow independant control of red or yellow, and add the black connector block.. right?

I hope I'm saying that right..

Attachments

Escher posted:Thanks Gents - Lots to think about...

Plus - now I have to go check my ZW wiring. I have one cord that I need to replace - but I also have to check the previous cord I replaced to see if I have the prongs connected correctly. Never gave it a thought with AC before..

it doesn't matter - just plug them in and perform the phasing procedure - turn it around if not in phase - then mark the plug with a sharpie.

I'll likely wire up a panel with ammeters and volt meters for each throttle as well.

I though the would be too cluttered - 2 for each handle + 4 per transformer - I looked for link to cheapies but goodies, but didn't find it - I'll look again...

....aaaand I still need to order a couple more switches before Tinman closes up shop for the year!

Escher posted:Question - If I connect up the two loops via switches - as shown below - I would need another block for just the black area, correct? But each of the two new switches would be contained in the red or yellow blocks.. that would still allow independant control of red or yellow, and add the black connector block.. right?

I hope I'm saying that right..

I wouldn't put that in - It seemed to be under control power- wise without that connection - it complicates things even more

This is why I operate command only![]()

![]()

The black curve doesnt need a block of its own because the turnout positions keep it out of use if you choose. Apply power from either the red or yellow block.

Bulbs in cars can blow when fed from two rollers which are far apart and bridging two blocks. Single roller cars, not much of an issue at all.

This would be an issue if an engine uses two rollers too. (most do have two rollers, but on one mount and single wire from there, not an issue for rolling equipment, and the short time it bridges two blocks doesn't usually effect things enough for any concern.)

Never leave stock bridging blocks though. That gives time for issues to ramp up between transformers and bite you.

2 diesels trucks, both with rollers, or an extra roller mounted on a tender, etc., would benefit from a.....

The solution is a polyfuse. A tiny disc about the size of a quarter at their largest (for our uses anyhow). It is a very fast acting fuse that will reset very fast once it is ok to do so (milliseconds).

One for each roller set. Not too expensive at all.

Phasing is easy, and those instructions are ok.

But to get a better grasp on why you do it, I suggest watching this link a few times (if it works) or ... Search youtube for lionel/phasing two transformers for use together. Mike isn't boring, over technical, etc.. I feel this is a great video for a novice or brush up on wave forms. About 20min.

Adriatic posted:Bulbs in cars can blow when fed from two rollers which are far apart and bridging two blocks.

I've never seen that, but wiring in cars between the two rollers can blow out/burn up when fed from rollers which are bridging two blocks, especially in the case of the Polar Express cars and similarly constructed ChiCom rolling stock.

That's right... too.

I should have mentioned that. But my bulbs blow very often when run across them.

I forgot a switch was open and cooked two more bulbs last month (one car 2-6v in series)

Cheap old bulk but still says something is up when they go two at a time, everytime. (I better make sure someone didn't vacuum and unplugged the Z.... no, I did that last time ... hey, I'm prtty sure you even pointed to that before on this matter Rob.)

I get the base theory the bulb isn't going to draw more amps because they might be available, and a wire melting and then a short are a more likely causes; but they are phased, no bad wires, and bulbs blow here.... a few melty plastic tabs etc. on mpc roller plates, but nothing detrimental to function of them either. (kinda impressive in a messed up way)

I figure there is a very fast spike in there. But why?, I'm kinda lost outside of maybe it is the smallest differences in phase timing during the change in the circuits or something. I.e. one cycle of being out of phase doubling voltage for just the one cycle or even half of one..? My theory on primaries vs secondary, phase, etc. and what else is happening here is kinda base stuff compared to You Rob. Especially phsically...tap postitions and combining of coils and thier tap positions or how phases and reading can be effected with something like 3 phase... bla bla bla...Design reasoning; that is where I have the most gaps and listen hard; definitely not my strongest suit.

My experience with multi-transformer set up and using it is roughly 5 years younger than me though. I saw a lot of bulbs do this on Gramps layouts as well before I added constant lighting to the daily runners. It had something to do with the blocks, that I do know (he also ran 2 ZW as one unit so that's all I know....my experiences say bulbs blow too. He really knew, I was just the smart shop monkey ![]() )

)

Point is bulbs are just the first thing that comes to mind now. But a bulb lost is not a loom; so not really the most important aspect; You're right.

Interesting.... For years I have ran many "layout" setups, some temporary while changing design, with use of two PW ZWs wired to various blocks. All I have ever done for blocks is isolate the center rail with a fiber/plastic pin designed for that. Or, sometimes, simply left a gap between rails. Even as far back as the 80s on my Houston area layouts, this worked fine for years on a given layout. Never have I blown any bulbs, or experienced any electrical issues crossing isolated pins while traversing blocks. Maybe an occasional change in speed, but nothing detrimental. Interesting...…. to say the least.

Jesse TCA

texastrain posted:Interesting.... For years I have ran many "layout" setups, some temporary while changing design, with use of two PW ZWs wired to various blocks. All I have ever done for blocks is isolate the center rail with a fiber/plastic pin designed for that. Or, sometimes, simply left a gap between rails. Even as far back as the 80s on my Houston area layouts, this worked fine for years on a given layout. Never have I blown any bulbs, or experienced any electrical issues crossing isolated pins while traversing blocks. Maybe an occasional change in speed, but nothing detrimental. Interesting...…. to say the least.

Jesse TCA

Thank you Jesse for joining in - I recall your large layout - your experience is the input that Escher needs -

Have any thoughts on how the layout should be wired? Escher has not kept the inner loops in a way that they can be isolated. Another pair of switches for each loop would do that. Any ideas would help. Maybe a link to your layout photos.

Have you kept the transformers phased?

I like this new plan a lot more than the previous!

There may be difficulty railing fresh stock with the turnout placements along the close edge. I always consider everyones styles and experiences differ though, and I don't discount them easily. Have you considered that railing within the switches might be difficult? (assuming that's where most of the stock would be swapped out)

Just food for thought. You can get better operation if you can locate the switches for the crossover on the curves, something like this. You don’t really need two double crossovers on a layout this size. FWIW, like Mark, I also like this design more.

Attachments

I like Dave's White-out and Magic Marker job even better. His placement of just one set of crossovers is good. I didn't think of it earlier

Mark Boyce posted:I like Dave's White-out and Magic Marker job even better. His placement of just one set of crossovers is good. I didn't think of it earlier

I did white-out because I’m on my iPad and not the laptop, so no SCARM. 🤪

BTW, I love the new iPad Pro, but have significantly mixed feelings about Apple. Having a heck of a time moving music and photos from the laptop. Can’t just copy them to an SD card and load them. 😠

In reference to the alternate placement of the single set of crossovers - I will take a look at changing the position - not sure if it will work or not with the spacing we have... but I'll check..