My parents (not extremely mechanically inclined) felt a need to lock "dissassembly" tools up to keep me out of them while unsupervised.

No pliers, wreches, or screwdrivers (Ha, they never caught on to the Boy Scout Knife's screwdriver.. but it was limited) I only had free reign over the floor grinder, hammer, saw, drill, woodburner, carving tools, & nails. All limits stemming from my pre-school removal of all near all of our doorknobs and pushing the square shaft in until the shaft and other knob was laying on the floor in each closed room. I got at least one tighter, but didn't know about lefty loose, righty tight yet. 🤣 Then there were those first reversed threads on the bicycle pedals

Anyhow, I took a HUGE risk, did not mind the rules, knew the box was open and repaired Mom's record player, broken for a few years, but she refused to let me try. The reject/start handle snapped, I made a small mending plate fit and added a tiny block of oak for a handle... it took total disassembling and reassembling in under 1-1/2 hrs to not be caught in the act. I stacked her fav records and after her return, played music until she noticed they were whole album sides playing.... after a scowl/grin, the boxes remained unlocked. (summer after 5th? ) ....I was the good one. My brother the cop and sister the social worker were the real trouble makers. They brought 7 strays home to live with us.

..... stray people

I have soldered with screwdrivers, nails/ and fat leather sewing machine needles; hat pins and even solid wire using propane torches/butane micro torches.... but I never used a team saw, and avoid table and cicular saws like they are sharks. I've seen too many short digits. I like chop saws though.

At the same time the coolest saw I ever ran was a Milwauke metal cutting circular saw. Imagine cutting 1/2" I-beam or bar stock with an only slightly heftier version of your normal circular saw. It took 7-10minutes on an automatic industrial chop saw at an early job (ran 4 at once)

All of a sudden giant gasoline driven cut off wheels messes are gone. Just "machine shop chips" to sweep up.

Tell the kids about weld flash & the build up of it, and drive it home not to watch torches, you may not be there when they see it at first... "eyeballs itch inside, and ache so bad you'll want to tear them out". (Grandfather's cobalt lensed, leather temple & cheek guard saftey glasses made this a very memerable lesson. Too cool.) Ha!, I recall hiding my eyes from the tv when Herman Munster and Lily were patriot welders. As an adult it's worse. I habitually turn my head, close my eyes, or nod to drop my mask down if I have a hat on, if welding or torchwork is on TV or anywhere near me really.

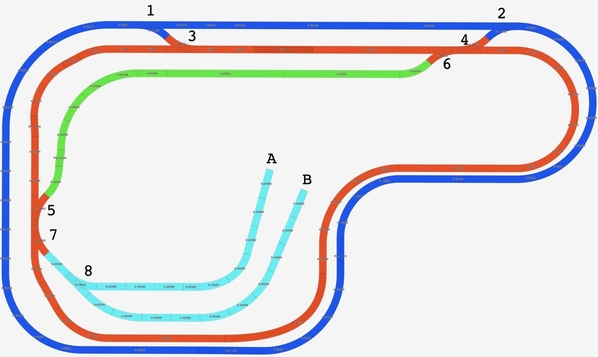

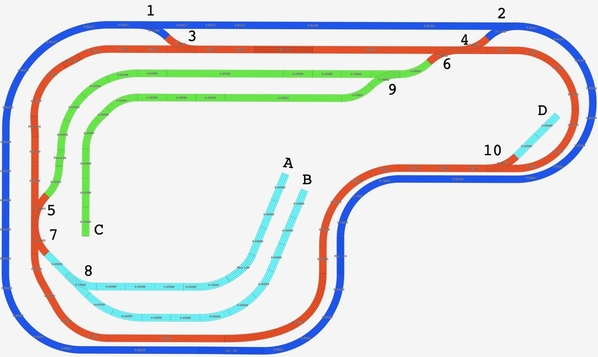

I even found myself doing it watching operating welding accessories on layout videos.

I have an uncle that had rebuilt and installed a V-8 in a car by second grade, mostly himself (huge kid, huge man... HE is the cherry picker if heads are off). He sold it and bought another. Repeat.

Grandfather was TEACHING welding by 17 and had me acting as an automatic drillpress monkey pre-school....and Gramps (other side, train guy, "all his fault") was either logging or in the steel mill where he would contently remain. Invited to, but never stepping into the hassle of management preferring to work with his hands and yell at lazy workers about screwing him, the company, and the union on his own accord  . (union means "team", no i )

. (union means "team", no i )

I sold woodwork for spending money. Early, it was woodburning signs, later clocks and odds & ends, a couple tables & a chair. (I made money in every school shop class I took; even drafting. I kept one table (still used) and a small fake electric guitar I would seranade the girls with in acts of hilarious public humiliation (it worked well enough  ) I sold the rest. (a friend bought a table with my name on it at a yardsale about 20 years ago thinking it was stolen, as I had been robbed a few years prior.) (if you include my youth my already varied adult careers it all becomes very wide spread set of experiences)

) I sold the rest. (a friend bought a table with my name on it at a yardsale about 20 years ago thinking it was stolen, as I had been robbed a few years prior.) (if you include my youth my already varied adult careers it all becomes very wide spread set of experiences)

I wonder when Da Vinci's parents unlocked his toolbox 🤣