I want to run a trolley layout with two lines that join at a switch and continue for about 2 sections of track before hitting a bumper and reversing. I don't want to have to constantly manually throw a switch to get the trolley to move over to the other line. Is there a way to have the switch automatically switch to the other line when the trolley passes the switch and hit the bumper and starts going forward?

Replies sorted oldest to newest

I have never done what you describe, but I bet it can be done using an insulated outer rail to activate the turnout.

I'll defer to the Forum mechanical experts, which I am not. Arnold

Easiest solution, put the switch machine button on the bumper and let the trolley push it.

Otherwise, I don’t see why you couldn’t rig up an isolated section of track to activate the the switch motor like an anti-derail would function.

Interesting idea about putting the switch on the bumper. Will see if the trolley generates enough force to do that. This would make life so much easier. Thanks!

I did that with a music spring wire. I run 3r trains back and forth 70' between loops at eye level. No switch machines, wires, toggles, electronics or relays to buy, install or fail. No drilling just remove a couple of spikes 7 ties in from the throw bar. Bend a "Z" in the wire end, insert it in the throw bar. Respike the wire along the stock rail then sit down with your favorite beverage and watch them run. It adds a background activity to my 2r RR.

Attachments

Tom Tee, how exactly does the wire throw the switch? I am still learning all the electrical ins and outs about trains.

What he did was make a spring switch. Just like the real thing on some railroads. The wheels push the points to the side and when the train passes it snaps back. You just have to watch out that you don't reverse movement halfway through otherwise one end of the car goes the alternate route.

Exactly. Different spring wires need moreor less length to provide soft point operation.

Thanks to all for the suggestions!

Richard, sorry to say, but if I understand the situation correctly, nobody has come up with the solution to your problem yet.

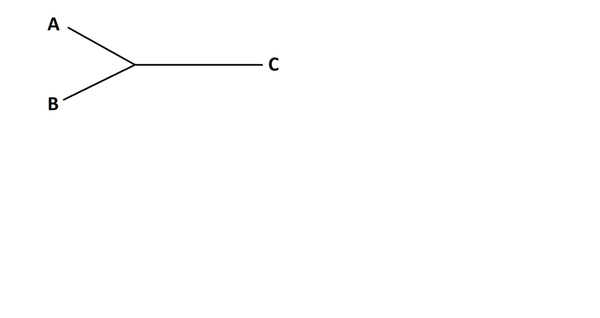

Let me restate the problem as I understand it. You have a switch in your trolley route. You want the trolley to use leg "A", then return and use leg "B" on the next trip. Repeat A, B, A, B...

This is a more complicated operational pattern than simple solutions can handle. Short of an electronic solution, I think it can be done with a couple relays and three insulated sections, one located on the A and B legs and one on the common leg.

Here's the logic: If A then B next, if B then A next, where A and B are the route last taken.

The way this works is one relay keeps track of A or B and the other relay throws the switch and latches or unlatches the first relay. Latching is when the power to the relay's coil is run through a set of the relay's contacts, thus holding it in the on condition. It doesn't matter which way it goes, but let's say B is latched and A is unlatched. This latching and unlatching is controlled by the insulated sections on the A and B legs. The third insulated section, on the common leg, would then tell the switch to throw in the direction indicated by the first relay, and reset the first relay to the next condition.

Sorry Tom, but a spring switch isn't going to work for this one, as there is no loop in the track plan. The shape is a "Y".

Big_Boy_4005 posted:Sorry Tom, but a spring switch isn't going to work for this one, as there is no loop in the track plan. The shape is a "Y".

Sorry Big Boy 4005,

It will work exactly like Tom said! No electrics needed!!!

Big Jim posted:Big_Boy_4005 posted:Sorry Tom, but a spring switch isn't going to work for this one, as there is no loop in the track plan. The shape is a "Y".

Sorry Big Boy 4005,

It will work exactly like Tom said! No electrics needed!!!

At least one of us doesn't understand the problem. A spring switch is always going to send the trolley on the same route. There is no way to make it alternate routes as the OP requested.

This is NOT a trailing point problem, this is a facing point problem, and a spring won't solve it.

I know what a spring switch is, and have a bunch of them on my layout, and they do what I want them to do, but this isn't it, unless I don't understand the problem. Tom's description of a spring switch is fine, but it is not the solution here.

Please read the original post again.

Rairoads used spring loaded switches for years,as well as trolley and traction companies.

This is something that can be made out of a manual switch and spring setup I'm sure.

The trailing point direction needs to be the reverse move,or the direction you run thru the switch.

mackb4 posted:Rairoads used spring loaded switches for years,as well as trolley and traction companies.

This is something that can be made out of a manual switch and spring setup I'm sure.

The trailing point direction needs to be the reverse move,or the direction you run thru the switch.

Nope. How does the switch change directions in the facing point movement? This is the crux of the problem. It must be an electrically powered switch. Spring won't do.

I was a computer science major in college. If there was one thing I learned from that experience, it was the "Universal problem solving algorithm". It is very simple, and has just four steps:

- Understand the problem!

- Have an idea

- Make sure your idea solves the problem

- Implement your idea

So far, suggestions offered have mainly failed on step one, not entirely understanding the problem.

Boilermaker1 posted:Easiest solution, put the switch machine button on the bumper and let the trolley push it.

Otherwise, I don’t see why you couldn’t rig up an isolated section of track to activate the the switch motor like an anti-derail would function.

This one actually made it to step three before running into trouble. How does the button know which way to throw the switch? A: You need a way to keep track of the current condition, then reset to the opposite at the end of each cycle.

If I seem a little passionate and perhaps defensive on this topic, it's because I have a good deal of experience dealing with relay logic to solve train movement problems like this one. To me this is a bit of a puzzle, one that I have never wanted to solve prior to this, but the gauntlet has been thrown.

I am not suggesting that mine is the only way to do this. However, of all the suggestions thus far, it's the only one that has solved the problem. I'm 99.9% sure this solution will work, as I have done a relay logic sequencing operation before, with a four track yard. This is just a two position task, as I explained in my first post here.

I'll put pencil to paper and draw a schematic as proof of the solution. It might take a day or so.

Coming from an electrical background myself, I can see how latching a relay would work - but I think there's an all mechanical answer out there, though it would require custom parts and such.

I keep thinking of marble runs - there's a device that does the motion we require, passes one direction, while setting itself for the opposite motion.

https://www.youtube.com/watch?v=oP1eIqCFhMo

Also one sprung switch wouldn't work, for the reasons listed.

But a Wye of sprung switches sends the trolley down both the legs in question - the problem here is, it doesn't go all the way to the top on one path.

Assume all switches are sprung to the right. The star indicates what I would normal consider the end of the line, from which the 2 routes diverge. As you can see, leaving from the bottom left, the trolley doesn't go to the star before heading to the start.

EDIT

I think I got it. We mentioned putting a switch button on the COMMON bumper-

Instead, put switches on the end of routes A and B, and wire it so it sends power to flip the switch the opposite way. Trolley goes down route A, hits bumper/switch, power sets switch for for route B. Trolley rolls though the switch, hits bumper and reverses, goes down route B. Repeat.

Attachments

The marble run was really cool, but I don't think it is applicable here. I also think you have the OP's track plan wrong. There's only one switch in the track, giving you three legs. Please correct me if I'm wrong, because everything I've said to this point is based on this track plan.

When the trolley gets to point C, you have to flip the switch the opposite direction. As I said earlier, you need to know where you came from. So when you reach A, you set the condition to B on the next throw. When you get to C, the switch throws routing you to B. When you get to B, you set the condition to A next, and arriving back at C completes the cycle. Repeat...

Attachments

OP, please post track plan.

Yeah, I get it, and that trackplan makes sense to the OP. I think my terminology fowled my idea.

To rephrase - Wire two buttons (electrical switches) at the bumpers at A & B, with wire all the way back to the turnout motor.

When the trolley hits point A, it will

1)change direction, running towards the turnout (switch)

2)Press the button (electrical switch), throwing the turnout (switch) toward route B

From there, the trolley heads towards C, running though the thrown turnout (switch) . After contacting the bumper at C, it reverses direction, and it will follow the turnout (switch) toward point B, where the opposite happens. Repeat.

Big Boy 45 has the layout down. The track configuration is a "Y". I like his and Lucky 13 thinking and analysis.

Thanks Richard.

Lucky, you can't throw the switch when the trolley is at A or B, because you still have to pass through it to get back to C, and once you get to C, it is thrown the way you last passed through, which means you go back to the leg you just left. Your method won't allow the trolley to use both routes. This fact demands that the throwing of the switch be triggered at C, so you need to keep track of where you came from, A or B.

That's the way the event sequence has to go.

I gave a good deal of thought to a mechanical solution, but couldn't think of a good way to throw the switch. It's a lot easier to direct the electrons to do the job, than an actual physical force.

I'm still working on the electrical schematic for this, I'm very rusty with relay logic, as I haven't used it in many years. I'm in the middle of step three of the algorithm. Richard, you get to do step four, but I'll be able to talk you through it.

BTW, I read the original post many times, and found it pretty clear, what the situation was. This is a tricky problem!