Looks like a hot rod waiting for her turn to show off! ![]()

Cut, cut, cut. We can't wrap this yet. The more pictures you post the more questions I come up with.

What are these wires for? I thought the pieces penetrating the side walls may have been stanchions for the hand rails but the wires look like power.

What are these wires for? I thought the pieces penetrating the side walls may have been stanchions for the hand rails but the wires look like power.

@coach joe posted:Cut, cut, cut. We can't wrap this yet. The more pictures you post the more questions I come up with.

What are these wires for? I thought the pieces penetrating the side walls may have been stanchions for the hand rails but the wires look like power.

Coach, ,…the wires are attached to the handrails, …those are the TMCC antennas,…the wires go to the radio board,…

Pat

Thanks Pat. That's what I was thinking they could be.

@Mark Boyce posted:Looks great, Pat!

John, when the time comes I hope you will update this thread with a look at what you add to the engine.

John definitely will as well as have a video on his channel at some point too. I wonder what cars John will run behind this puppy?

Upgraded smoke as well I hope?

Jon ![]()

@KOOLjock1 posted:Upgraded smoke as well I hope?

Jon

John will probably be doing that as he is an electronic wizard. Pat doesn't like playing with stuff like that unless he has to.

It would definitely have been a more robust conversion on my own C&O Hudson had I easy access to some of the parts used here. Specifically ,a flywheel equipped motor and a CV type drive shaft. Still, I'm pleased with the results on my ongoing project. I can only imagine how satisfied John will be with the fine workmanship performed by Pat.

Off topic slightly, I never was thrilled with the silver paint that simulated the stainless panels covering the loco and tender. I stripped it, scrubbed the bare metal then clear coated it all.

Bruce

@KOOLjock1 posted:Upgraded smoke as well I hope?

Jon

Jon, good point. I expect John will have that yellow belly belching out smoke with his great products. It will be a sight to behold!

For sure it'll get fan driven smoke, the Super-Chuffer, etc. I'll have to see if I can fit the drive electronics in the locomotive so I can do a wireless IR drawbar.

Can't wait to see her in action. I always thought this casting was just screaming for a Legacy style upgrade!

Jon ![]()

@gunrunnerjohn posted:For sure it'll get fan driven smoke, the Super-Chuffer, etc. I'll have to see if I can fit the drive electronics in the locomotive so I can do a wireless IR drawbar.

John, the weight I added is bolt on, you can move it or change it as you see fit, …..my only suggestion would be not to put weight directly on the boiler shell, ….I’ve seen that done before, and it caused shell sagging in short order,….that was done on a Yellow Belly, and the results were kinda ugly,…....but you can move the weight or change it to have room for boards and what not,…

Pat

Pat, I'll have to figure it out when I see it and have all the parts on the bench. I can also sprinkle some smaller weights around, I have been known to "take a shot" at that approach. ![]()

![]()

This added over a pound to the weight of the HHP-8, and really made a huge operational difference.

Attachments

@gunrunnerjohn posted:For sure it'll get fan driven smoke, the Super-Chuffer, etc. I'll have to see if I can fit the drive electronics in the locomotive so I can do a wireless IR drawbar.

It should fit John. Not a Cruise Commander but rather an R4LC on a motherboard plus a DCDE in my CV. A CC should be shorter and no higher.

Pete

Attachments

Looks good Pete, I need the extra space to cram my Super-Chuffer in there! ![]()

@gunrunnerjohn posted:Looks good Pete, I need the extra space to cram my Super-Chuffer in there!

It should fit under the smoke unit. My mount could be smaller but there is a board for an optical chuff switch under that mount. I wasn’t trying to be too economical with space.

Pete

May be I missed it, but does any one know who did the motor conversion ![]() ? I have the silver Lionel Commodore Vanderbilt and would love get that horrific Lionel motor replaced with a can motor.

? I have the silver Lionel Commodore Vanderbilt and would love get that horrific Lionel motor replaced with a can motor.

Interesting flywheel on your motor, what was the purpose of that shape? ![]()

@Junior posted:May be I missed it, but does any one know who did the motor conversion

? I have the silver Lionel Commodore Vanderbilt and would love get that horrific Lionel motor replaced with a can motor.

Look at the originator of this thread, Pat @harmonyards is the guy that does these Pittman motor upgrades.

Pat is THE MAN, Junior! 👍🏻

Hey! Thanks for all the quick responses everyone! Hmmmm....maybe I need to ask Santa for an addition to my Christmas list!

I think Pat has cornered the market on Pittman motors, he has piles of them just waiting to go into willing locomotives! ![]()

![]()

@Junior posted:Hey! Thanks for all the quick responses everyone! Hmmmm....maybe I need to ask Santa for an additional to my Christmas list!

Search up "Tales from the Harmon Shops" to see some of the other conversions/massive improvements to older engines. Be warned though, you may want to get all in. I already have had Pat do a Mohawk to a much better one, he has 2 Hudson's, I plan on getting both CV Hudson's to him, as well as a slew of other projects. I have been keeping a spare eye on some of the older Mohawk's about the place and am thinking on more modifications to the older ones. Some of the other projects in mind won't be going to Pat because there already is Pittman's in them and the details shouldn't need Pat's expertise. However, I will naturally consult him on options to anything that would be purchased in the future.

Good information for Junior, Dave. Yes, I saw a few of these threads and decided to get on the K-Line NYC Hudson platform even though I'm a Western Maryland/B&O fan. The NYC Hudson is a classic, not to mention the Mohawks, etc. As Pat mentioned above, he has my Hudson. Why not join into the frenzy?!

Mark....I concur....this is great information. Thank you so much for sharing Dave!

The great thing is with both Pat, John and Pete is this topic, there is a ton of useful information from great minds as well as engineering the very cool. Pat will tell you, Pete is the master. John knows way more about electronics than any other person I know(may be others, but they're not currently in this topic). You should ask Pat how is his Hudson's coming along. He could make the entire NYC roster.

@harmonyards, Pat, does this mean that this Hudson is on its way back to John or is there just a bit more to do before heading out?

It'll be coming back soon, he's going to put his little Chuff-Generator mounting bracket on it, makes it easier to mount the C-G instead of on the motor.

@gunrunnerjohn posted:It'll be coming back soon, he's going to put his little Chuff-Generator mounting bracket on it, makes it easier to mount the C-G instead of on the motor.

The wonders of the Harmon Shops John, gotta love it. He did wonders on my 18009 Mohawk to make Alex's work a piece of cake.

I also did the same Mohawk for a customer, and Pat's excellent Pittman install made the rest pretty easy.

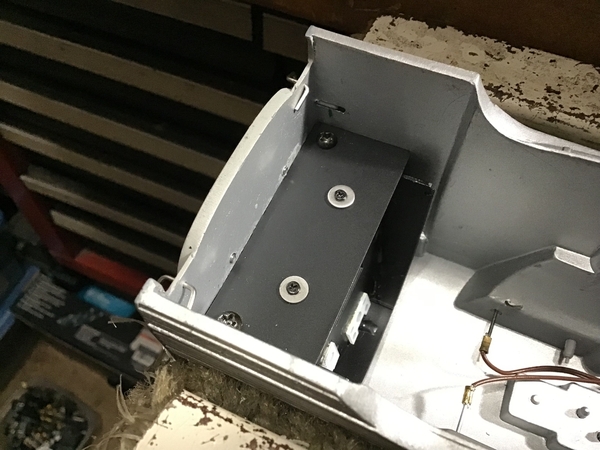

This is the bracket that John’s referring to, that I’ve added for him,….it overhangs the flywheel in just the right place to mount the chuff sensor ……also gives a convenient place to route wires, etc, so they ain’t getting tangled up in the rotating mass…..NOW, it’s ready to go home…..😄

Attachments

Awesome Pat.

Thank you Dave, ….do it right, or don’t do it,….😉

Pat

Just as long as it isn't me. When I do some projects, I get into the mode of trying to make it so right, that it winds up taking me a lot longer than I should. I have gotten a lot better with taking shorter than longer. Still though, I take a while to get things done when I've starter it. Yeah, it is done right, just takes a while.

@brwebster posted:It would definitely have been a more robust conversion on my own C&O Hudson had I easy access to some of the parts used here. Specifically ,a flywheel equipped motor and a CV type drive shaft. Still, I'm pleased with the results on my ongoing project. I can only imagine how satisfied John will be with the fine workmanship performed by Pat.

Off topic slightly, I never was thrilled with the silver paint that simulated the stainless panels covering the loco and tender. I stripped it, scrubbed the bare metal then clear coated it all.

Bruce

Bruce, ….Let’s see your Yellow Belly on here, …..take some pics of your build, and post them up on here, ….we’ll use this thread to share ideas, and swap design elements. Especially what you did to the paint. It’s always great when a thread becomes a useful tool for the modelers on here,…..I have no problem with any others that have modified ex-Pulmor engines sharing a thread ……instead of the thread just being a story, it becomes a resource, …..and that’s handy!…😉

Pat

I'd like to see the paint on the Yellow Belly too. ![]() After spending all the effort on this, if there' further improvement, might as well consider it.

After spending all the effort on this, if there' further improvement, might as well consider it. ![]()

You know it is always good to see some other things going on with an engine or an engine that is somewhat similar. I think that we have had a few of Pat's posts show just more than what he was working on, which I must say is most enjoyable. It is a good thing to have fresh takes and ideas on how to approach what was done to an engine. I can't wait to see what else comes on this as well.

An interesting thread. Dave’s reference to the 785 Hudson opens the door to a cosmetically altered Hudson pictured here. Scale pilot wheels and a full size tender were substituted in a conscious effort to move it a bit more from “Semi” to “Scale. As it's a fantasy engine, I also took the liberty of having a grey steam chest

This loco ran at the San Diego 3-Railers club for several years, electro-mechanical e-unit reverser and all. My Williams brass GS-4 had been successfully upgraded with a QSI sound system (forerunner to Mike’s Proto-1) in the early nineties, and I wanted the same for the 785. Pat Quinn of QSI stated that satisfactory chuff generation with their existing technology would be difficult to regulate because of the “dirtier” electrical environment in AC Pulmor motors. He asked if I would work with him to test any forthcoming AC motor sound system on a typical user layout. The prototype Pat developed went back and forth between Beaverton and SoCal several times before he said “that’s the best I can make it.” How far we have come with GRJ, et. al. ![]()

If I were still running trains in San Diego, I would indeed consider enrolling my 785 in Pat’s Motor Works Program, as I prefer can motors over “grinders.”

as I prefer can motors over “grinders.”

Attachments

My C&O Yellowbelly arrived home, Pat's work looks great. I had it apart checking for fit to see where things will fit. I have to say, the cab interior from the Vision Line Hudson really adds some POP! I'm trying to figure out how I'll light the gauges, firebox, etc.

It has to live on the shelf for a few days until I complete a couple of projects already filling up the workbench. ![]()

John, It just arrived, and you took it apart already!! ![]()