Hello all

Fred Icken was one of the O scale pioneers ..beginning in 1927 ..some of his first pieces were a bit "basic" ...but he joined up with Barker in 1930 and the models took an up turn in design and performance. The Icken and Barker marriage lasted only till April of 1930 .....but the high quality ..and always improving continued with Fred Icken's work for the next several decades.

PRR engines were the go to steamers for early manufactures .. high stepping E6 and K4's ... looked great and could take a 36" radius curve ... space has always been a factor in selling O scale .

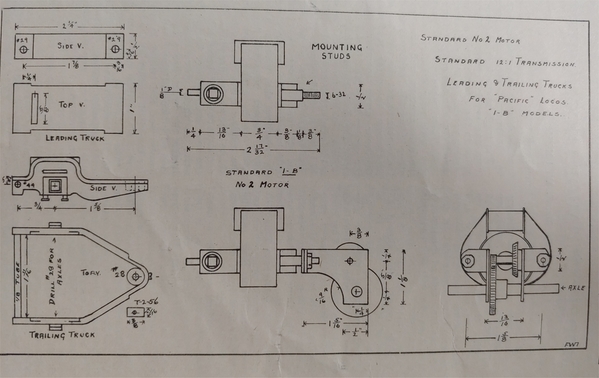

Fred Icken wrote a series of article for Modelmaker covering the new line of engines beginning August 1930 ... covering the E6 and K4 . Retail pricing E6 ..$60.00...K4 $90.00 ........big time money in 1930 .

Double gear reduction is similar to Paul Egolf's , who had been building scale models since 1924 . Icken did beef up the drive ...and would change it again for the fair engines of 1933.

Here we have a 1930-31 Icken-Barker ......and a 1931-32 Icken K 4 ...note more details ... price had climbed to the $150.00 range at this time .... video clip shows the pair double heading pulling 9 ( heavy) Walthers ..with original Walthers trucks ....

Cheers Carey

oh yes running outside 3rd rail ...which came into being about 1929 ..

![0715192250[1] 0715192250[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/93080578941050987/filePointer/93080578941051045/fodoid/93080578941051037/imageType/MEDIUM/inlineImage/true/0715192250%255B1%255D.jpg)

![0716190133a_HDR[1] 0716190133a_HDR[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/93080578941050987/filePointer/93080578941051046/fodoid/93080578941051038/imageType/MEDIUM/inlineImage/true/0716190133a_HDR%255B1%255D.jpg)

![0716190133b_HDR[1] 0716190133b_HDR[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/93080578941050987/filePointer/93080578941051047/fodoid/93080578941051039/imageType/MEDIUM/inlineImage/true/0716190133b_HDR%255B1%255D.jpg)

![0715192250[1] 0715192250[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/93080578941050987/filePointer/93080578941051045/fodoid/93080578941051037/imageType/SQUARE_THUMBNAIL/inlineImage/true/0715192250%5B1%5D.jpg)

![0716190133a_HDR[1] 0716190133a_HDR[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/93080578941050987/filePointer/93080578941051046/fodoid/93080578941051038/imageType/SQUARE_THUMBNAIL/inlineImage/true/0716190133a_HDR%5B1%5D.jpg)

![0716190133b_HDR[1] 0716190133b_HDR[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/93080578941050987/filePointer/93080578941051047/fodoid/93080578941051039/imageType/SQUARE_THUMBNAIL/inlineImage/true/0716190133b_HDR%5B1%5D.jpg)

![0716190123a[1] 0716190123a[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/93080578941050987/primaryPicture/true/filePointer/93080578941051044/fodoid/93080578941074258/imageType/SQUARE_THUMBNAIL/inlineImage/true/frame/FIRST/thumbnail.jpg)

![0715192240[1] 0715192240[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/93080578941050987/primaryPicture/true/filePointer/93080578941143234/fodoid/93080578941156871/imageType/SQUARE_THUMBNAIL/inlineImage/true/frame/FIRST/thumbnail.jpg)