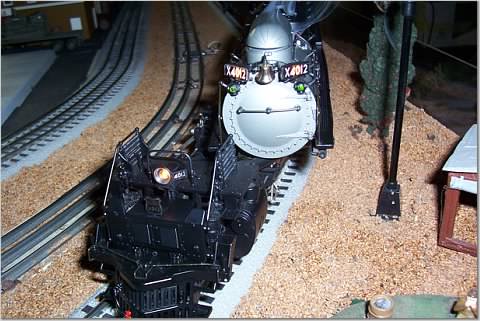

Well, after an amazingly warm welcome, I've decided to start a build thread. If you missed my intro, i'm a career railroader and model train collector. The locos and cars have set on shelves and static displays for too long and it's time to build a layout to run them. We have a dedicated home theater that has run it's course and is being gutted and sold off. This leaves me with a 21x21 area to create. I'll be running, among other locos, a MTH premier Big Boy and DD40X so I know I will need minimum O-72 curves.

I've purchased a new TIU (rev L) and remote so I should be good on DCS control. I'll be using MTH Realtrax as I already have a small assortment and it just seems easy to work with.

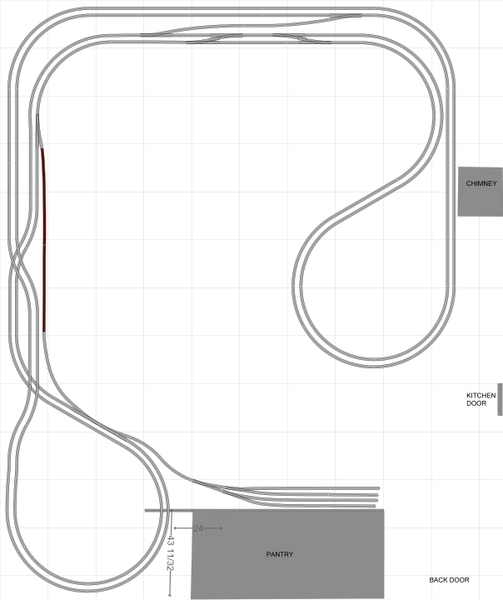

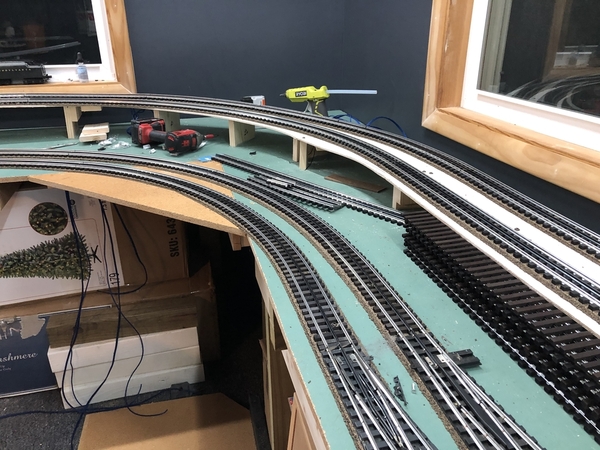

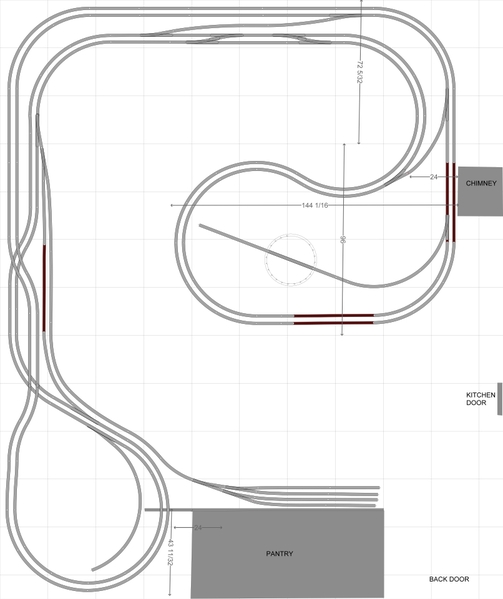

I'm using Anyrail software and have come up with a basic "flow" I want to build. Go easy on me, as this is just a design flow and by no means the final build. I would like a double main in most areas but do not want two tracks to just follow each other around the entire time. Inspiration is coming slower than I would like, but I have the desire, and some space, so it's a start. The general plan is to build along the walls and not make the room seem "crowded" or filled to capacity. I also have no desire to plan and build for 6 months before a train ever hits the track. I'd like to get a base layout running soon and while ugly, have it operational. Then inspiration can lead me to scenery and extras.

I'm going to attempt to attach what I've come up with so far as far as a "flow" desire goes.

Thanks in advance, and I am completely open to suggestions...