GN Z-6 4-6-6-4 Tenshodo WOW 101 decoder install.

Well, glad this was the second complex install and not the first as it took a full day to get everything working.

Forgot to install the resistor for the engine marker lights and they burned out.

After replacing the LED's, I failed to check if the engine marker LED light wires were not touching the brass castings and they shorted out.

Then I did the same for the tender marker lights, not checking for being grounded and those burned out.

I started yesterday morning and finished this morning. Good thing this is a hobby as you couldn't pay me enough to do this as a job!

One nice thing about putting in 3 harnesses in the install:

Any problems, break up the components to at least find the general area at fault.

Also, maintenance will be much easier.

WOW also has two harnesses so swapping out a decoder is easy should it 'smoke'.

Short test video:

I love the coasting affect when power is reduced and the side rods clank and the brakes squeal.

Jor, a railroad friend, showed me how to reduce the chuff rate. For the most part, hit F8 four times and follow the instructions which is mostly option 3 and then keep hitting F1 until 4 chuffs a revolution. Had to hit a lot of F1's to reduce it.

Also, interesting was no chuff when testing the engine, on it's back, with just one set of drivers. I had to put some resistance to the drivers to cause the chuffing to work. The engine with the large can motor and the extremely quiet and smooth gear drive mechanism must not create enough current draw to start the chuffing.

This engine also goes into 'stealth' mode when the sound is turned off.

https://www.youtube.com/watch?...amp;feature=youtu.be

Cut a square out under the tender for the connection. Works nice this way as the 8 pin connector can slide into the bottom of the tender.

Slot is below the deck so not visible.

Pre-disassembly.

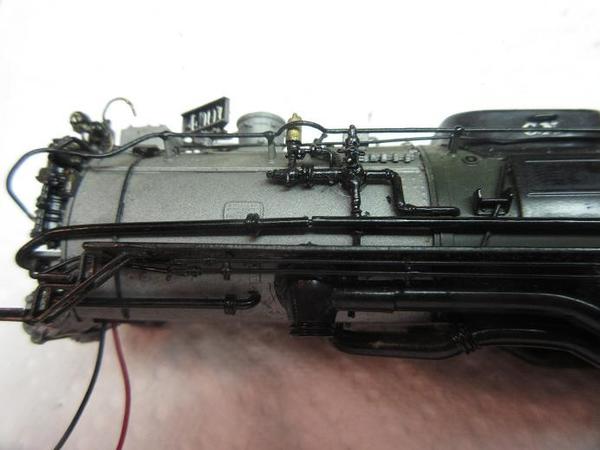

Lots of weight but, again, there happened to be a small hole along the boiler for the wires.

Marker lights drilled out.

Painting the insides helps keep the bare LED wires from contacting the brass casting and grounding out, unless you burn them out and, when pulling out the old ones the paint is also removed so the next time, they short out!

Holes for running board lights.

Tender marker lights and headlight drilled out.

Testing but I forgot to test if they are grounded.

Tender lights.

Forgot that installing the LED's, previously, added to the total time spent on the install.

Filed a small groove for the headlight wires.

Nice 'touch' by Tenshodo; the front of the firebox is screwed on instead of just the usual friction fit.

Lots of fun soldering 8 #30 wire to a connector less than a 1/2" wide!

Bench test motor and sound before doing lights.

Good thing that tender is large!

Another nice construction by Tenshodo: that main steam pipe has a telescopic tube so the front of the pipe can be removed when the smoke box front is removed (just above running boards and just back and below whistle).

Wire harness (4 pin) for the lights in the boiler section. One blue (hot) and 3 for grounds of LED's.

Two pin connector to make maintenance of the pilot easier to work on.

Another nice Tenshodo build is a wire maintaining straight and downward pressure of the trailing trucks.

Finally, all together.

Digital cameras don't like led's!

Running board lights.

Cab light and fire box glow.